Temperature control precision is the defining variable regarding the structural integrity of cubic boron arsenide (c-BAs) crystals during their extended growth cycles. Because the formation of c-BAs relies on a gradual process of diffusion and deposition, any deviation in furnace temperature disrupts the equilibrium, leading directly to dislocations and compositional inhomogeneity within the crystal lattice.

The successful growth of c-BAs is less about reaching a peak temperature and more about maintaining unwavering stability over time. Precision prevents the lattice defects that occur when the delicate balance between diffusion and deposition is disturbed.

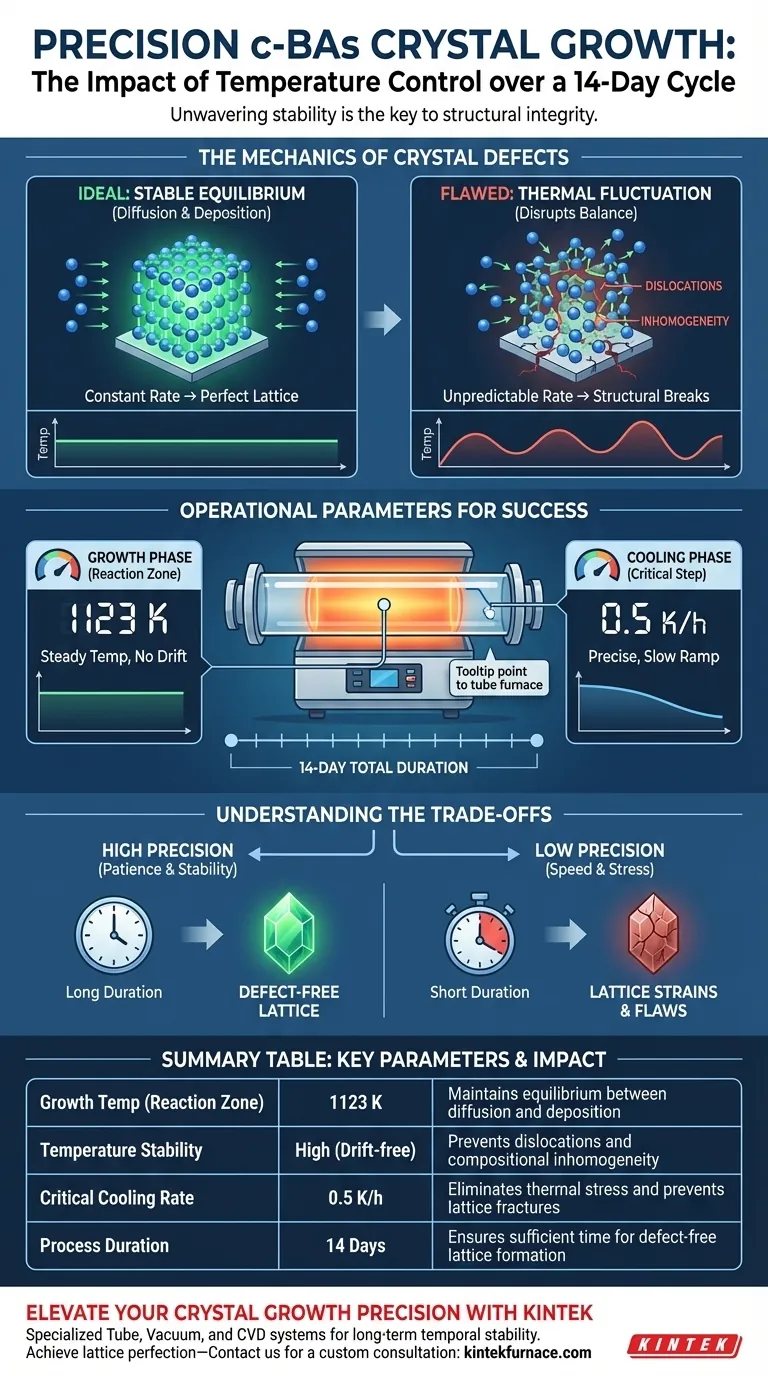

The Mechanics of Crystal Defects

The Role of Diffusion and Deposition

The growth of cubic boron arsenide is not instantaneous; it is a cumulative process driven by diffusion and deposition.

For the crystal lattice to form correctly, these physical processes must occur at a constant, predictable rate.

Consequences of Thermal Fluctuation

If the temperature fluctuates, the rate of deposition changes unpredictably.

This instability prevents the atoms from settling into their ideal positions, resulting in dislocations (structural breaks) or compositional inhomogeneity (uneven distribution of elements).

Operational Parameters for Success

Maintaining the Reaction Zone

To ensure uniformity, the furnace must maintain a constant reaction zone temperature throughout the growth phase.

Primary success has been observed at a steady temperature of 1123 K. Holding this temperature without drift is essential for the long-term stability of the crystal structure.

The Importance of Cooling Rates

The growth cycle concludes with a critical cooling phase that determines the final lattice perfection.

A precise, slow cooling rate of 0.5 K/h is required. This gradual reduction allows the crystal structure to settle without inducing thermal stress or fractures.

Understanding the Trade-offs

Time vs. Structural Integrity

Achieving a defect-free lattice requires patience; the 0.5 K/h cooling rate significantly extends the total process time.

Attempting to accelerate this cycle to save time will almost invariably result in a lower-quality crystal with significant lattice strains.

Equipment Stability vs. Duration

Maintaining precision over a two-week cycle places immense stress on standard heating elements and controllers.

Standard furnaces may drift over long periods; therefore, equipment capable of long-term temporal stability is a non-negotiable requirement for this specific material.

Optimizing Your Growth Strategy

To ensure high-quality c-BAs growth, align your equipment capabilities with these specific thermal requirements:

- If your primary focus is Lattice Perfection: Prioritize a controller capable of executing the 0.5 K/h cooling ramp without stepping or overshooting.

- If your primary focus is Compositional Uniformity: Ensure your furnace can hold the reaction zone at exactly 1123 K for the full duration of the diffusion phase without fluctuation.

Precision in temperature control is not merely a feature of the furnace; it is the architect of the crystal's quality.

Summary Table:

| Parameter | Ideal Value | Impact on c-BAs Growth |

|---|---|---|

| Growth Temp (Reaction Zone) | 1123 K | Maintains equilibrium between diffusion and deposition |

| Temperature Stability | High (Drift-free) | Prevents dislocations and compositional inhomogeneity |

| Critical Cooling Rate | 0.5 K/h | Eliminates thermal stress and prevents lattice fractures |

| Process Duration | 14 Days (2 Weeks) | Ensures sufficient time for defect-free lattice formation |

Elevate Your Crystal Growth Precision with KINTEK

Success in synthesizing cubic boron arsenide demands unwavering thermal stability that standard lab equipment simply cannot provide. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Vacuum, and CVD systems designed for long-term temporal stability and ultra-precise ramp control.

Whether you need a horizontal tube furnace capable of maintaining 1123 K for weeks or a controller that masters 0.5 K/h cooling rates without stepping, our customizable high-temperature solutions are engineered for your most sensitive research.

Achieve lattice perfection—Contact KINTEK today for a custom consultation!

Visual Guide

References

- Jae‐Hoon Kim, Joon Sang Kang. Isotope‐Enriched Cubic Boron Arsenide with Ultrahigh Thermal Conductivity. DOI: 10.1002/advs.202502544

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is Physical Vapor Deposition (PVD)? Master Thin Film Coating for Enhanced Materials

- Why is a precision furnace required after TiO2-alpha-Ga2O3 synthesis? Master Phase Transformation & Interface Bonding

- Why is a mixture of Argon (Ar) and Hydrogen (H2) required during beryl heat treatment? Master Color Transformation

- Why is carbon dioxide utilized for the in-situ gasification regeneration of NiCuCe catalysts? Enhance Catalyst Longevity

- What are the process advantages of using an electric melting furnace with an adjustable thermostat? Optimize Copper Scrap Refining

- What is the function of the slow cooling feature in a furnace for Li2.7Sc0.1Sb? Master Single-Crystal Quality

- What are the specific functions of a flowing 5% H2/Ar gas mixture? Master Thermal Reduction of Nanoparticles

- Why is rapid air cooling preferred over furnace cooling for TS-Ir/MnO2? Optimize Catalyst Lattice Strain