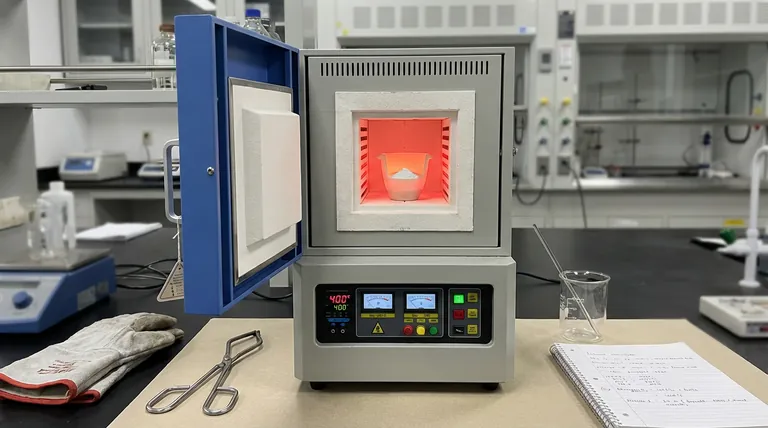

The primary function of the laboratory oven or muffle furnace is to execute a precise air annealing treatment at 400°C for 4 hours immediately following hydrothermal synthesis. This thermal processing step is the mandatory bridge that transforms raw precursor chemicals into a functional composite material suitable for high-performance applications.

The furnace is not merely for drying; it is essential for driving the chemical dehydration of precursors into crystalline nanorods and solidifying the physical bond between the TiO2 and alpha-Ga2O3 layers.

Driving Essential Phase Transformations

Converting the Precursor

The hydrothermal synthesis process does not immediately yield the final alpha-Ga2O3 material. Instead, it produces an intermediate precursor known as gallium oxide hydroxide (GaOOH).

The Dehydration Mechanism

The heat from the furnace triggers a critical chemical reaction. By maintaining a steady temperature of 400°C, the furnace drives the dehydration of the GaOOH precursor.

Achieving Crystallinity

This dehydration process is what ultimately forces the phase transformation. It converts the intermediate material into highly structured, crystalline alpha-Ga2O3 nanorods.

Enhancing the Heterojunction Interface

Strengthening the Physical Bond

Beyond chemical changes, the annealing process serves a structural purpose. The thermal treatment significantly enhances the bonding strength at the interface where the TiO2 and alpha-Ga2O3 meet.

The Criticality of the Interface

This contact point, known as the heterojunction interface, is the most critical area of the composite. A weak bond here results in poor electron transfer and structural instability.

Impact on Device Utility

The integrity of this interface is directly linked to the final application. Strong interfacial bonding is explicitly cited as vital for the performance of the resulting photodetector.

Understanding the Risks of Imprecision

The Necessity of Specific Parameters

The requirement for "precision" equipment is dictated by the specific parameters of 400°C for 4 hours. This is not a generalized heating step; it is a calibrated recipe.

Consequences of Deviation

Failing to maintain this specific temperature profile risks incomplete phase transformation. If the GaOOH is not fully dehydrated, the material will lack the crystalline alpha-Ga2O3 nanorods required for the device to function.

Optimizing for Photodetector Performance

To ensure successful synthesis of TiO2-alpha-Ga2O3 composites, consider your equipment choice based on the following goals:

- If your primary focus is Material Purity: Ensure your furnace can maintain a stable 400°C to guarantee the complete dehydration of GaOOH into crystalline alpha-Ga2O3.

- If your primary focus is Device Reliability: Prioritize the annealing duration (4 hours) to maximize the bonding strength at the heterojunction interface, ensuring robust photodetector performance.

Precision thermal treatment is the definitive step that turns a chemical mixture into a high-performance electronic component.

Summary Table:

| Process Phase | Primary Goal | Temperature/Time | Outcome |

|---|---|---|---|

| Phase Transformation | Dehydration of GaOOH | 400°C | Formation of crystalline alpha-Ga2O3 nanorods |

| Interfacial Bonding | Heterojunction Strengthening | 4 hours | Enhanced electron transfer & device stability |

| Final Application | Device Optimization | Post-Synthesis | High-performance photodetector functionality |

Elevate Your Material Research with KINTEK Precision

Don't compromise your TiO2-alpha-Ga2O3 composite performance with inconsistent thermal profiles. KINTEK provides the high-precision Muffle, Tube, and Vacuum furnace systems necessary to achieve exact phase transformations and robust heterojunction interfaces.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to meet your unique laboratory requirements for 400°C annealing and beyond. Contact us today to discuss how our specialized high-temp furnaces can ensure the success of your next synthesis project.

References

- Wenxing Zhang, Wanjun Li. A Facile Synthesis of TiO2–α-Ga2O3-Based Self-Powered Broad-Band UVC/UVA Photodetector and Optical Communication Study. DOI: 10.3390/ma17164103

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the use of a stainless steel high-pressure autoclave affect ZnS/CeO2@CNT formation? Optimize Catalyst Growth

- How does an annealing furnace work? A Guide to Controlled Heat Treatment

- How do high-power IR furnaces compare to traditional equipment for nanocomposites? Unlock Superior Material Control

- What are the primary advantages of using powder metallurgy for Ti and TiZr alloys? Achieve Ultimate Structural Precision

- What is the primary function of drying bovine horn biomass for PVC biocomposites? Optimize Material Strength

- Why is thermal insulation applied to cylindrical components in thermal stress tests? Enhance Calculation Precision

- What role does high-flow nitrogen play in ITO thin film annealing? Protect Conductivity & Surface Purity

- What factors should be considered when selecting a furnace based on processing requirements? Optimize Your Thermal Process with the Right Equipment