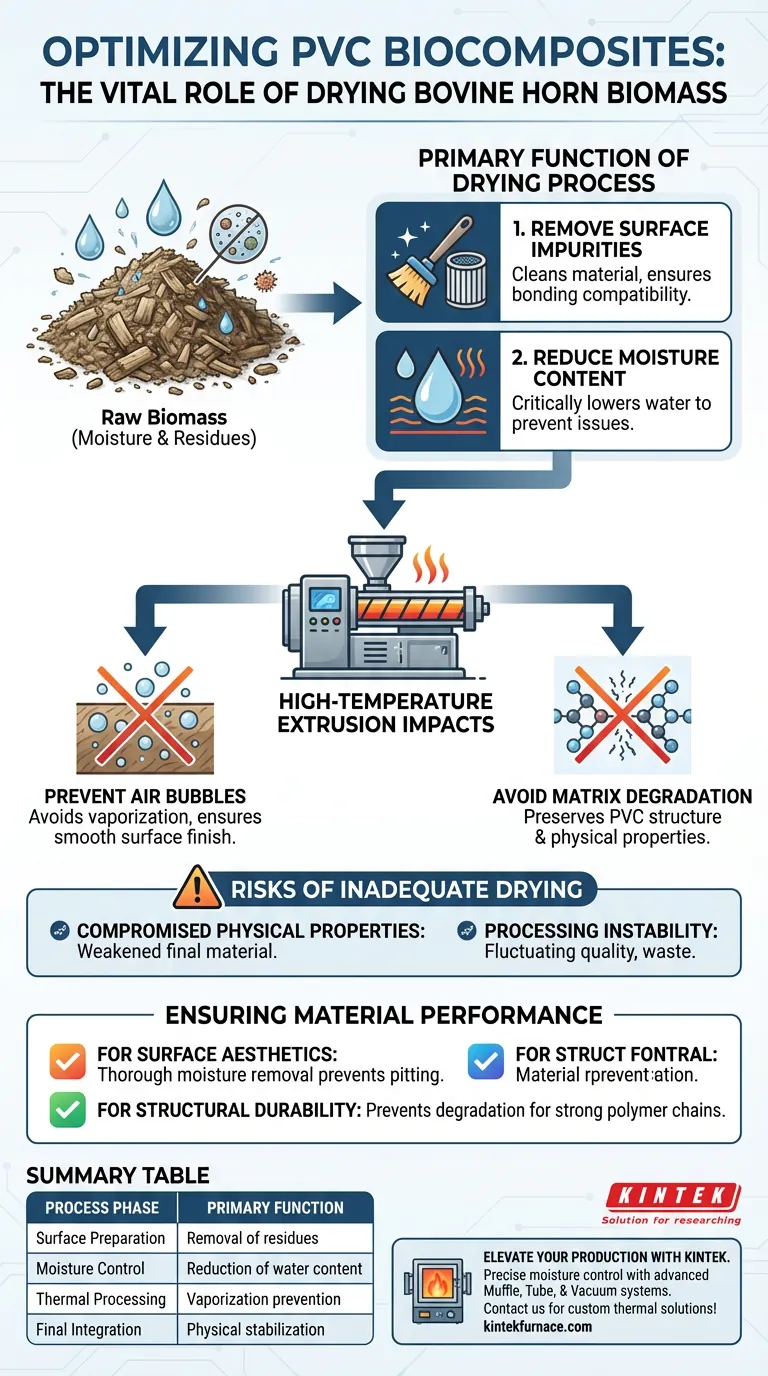

The primary function of the drying process for bovine horn biomass is to remove surface residues and critically reduce moisture content prior to composite formation. This step ensures the cleanliness of the raw material and prevents water vapor from compromising the PVC matrix during high-temperature extrusion.

Moisture control is the defining factor in biocomposite quality; failure to dry the biomass leads to air voids and matrix degradation, directly weakening the physical properties of the final material.

The Role of Drying in Material Preparation

Removal of Surface Impurities

Before the biomass can be integrated into the polymer, it must be chemically and physically stable. Drying serves as a purification step, effectively removing surface residues that could interfere with bonding.

This ensures that only clean, compatible biological material enters the processing phase.

Reduction of Moisture Content

Bovine horn biomass naturally retains water, which is incompatible with hydrophobic polymers like PVC. The central mechanical goal of this process is to significantly lower the moisture content of the raw material.

By extracting this moisture beforehand, you prepare the biomass for the thermal stresses of the manufacturing process.

Critical Impacts on High-Temperature Extrusion

Preventing Air Bubble Formation

During the extrusion process, materials are subjected to high temperatures that far exceed the boiling point of water. If moisture remains within the biomass, it will vaporize instantly, generating air bubbles within the composite.

These voids interrupt the material structure, creating weak points and ruining the surface finish.

Avoiding Matrix Degradation

Water does not just create voids; it actively reacts with the polymer matrix under heat. Excess moisture during extrusion causes matrix degradation, breaking down the PVC chains.

This chemical breakdown compromises the structural integrity of the composite, leading to a product with inferior physical properties.

The Risks of Inadequate Drying

Compromised Physical Properties

The ultimate trade-off in this process is between preparation time and final material strength. Skimping on the drying phase directly results in a failure to preserve the physical properties of the composite.

Processing Instability

Inconsistent drying leads to inconsistent extrusion. If the biomass is not uniformly dry, the manufacturing process becomes unpredictable, resulting in fluctuating quality and increased material waste.

Ensuring Material Performance

To maximize the quality of your PVC biocomposites, prioritize the drying phase based on your specific performance requirements:

- If your primary focus is surface aesthetics: Ensure thorough moisture removal to eliminate the vaporization that causes visible air bubbles and surface pitting.

- If your primary focus is structural durability: Prioritize drying to prevent matrix degradation, ensuring the PVC polymer chains remain intact and strong.

The success of a PVC biocomposite relies less on the mixing and more on the rigorous preparation of the biomass components.

Summary Table:

| Process Phase | Primary Function | Impact on Quality |

|---|---|---|

| Surface Preparation | Removal of residues | Ensures bonding compatibility with PVC |

| Moisture Control | Reduction of water content | Prevents air voids and surface pitting |

| Thermal Processing | Vaporization prevention | Protects polymer chains from degradation |

| Final Integration | Physical stabilization | Maximizes structural integrity and durability |

Elevate Your Biocomposite Production with KINTEK

Precise moisture control is the foundation of high-performance PVC biocomposites. At KINTEK, we understand that material preparation requires rigorous thermal precision. Our expert R&D and manufacturing teams provide advanced Muffle, Tube, and Vacuum systems specifically designed to stabilize biological additives and prevent matrix degradation.

Whether you need customizable high-temp furnaces or specialized drying solutions, we help you eliminate processing instability and maximize material durability. Contact us today to find the perfect thermal solution for your lab!

Visual Guide

References

- Hamza Ennadafy, Naoual Belouaggadia. Thermogravimetric Analysis of Rigid PVC and Animal-Origin Bio-Composite: Experimental Study and Comparative Analysis. DOI: 10.18280/ijht.420105

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

People Also Ask

- How are thermal processing equipment commonly categorized? Choose the Right Furnace for Your Lab

- Why Use a Vacuum Drying Oven for Ti3C2 MXene@NiS or Co4S3? Prevent Oxidation and Preserve Catalyst Integrity

- What is the purpose of adding metal oxides such as copper oxide (CuO) in RAB? Enhancing Air Brazing & Ceramic Bonding

- What advantages does peat char offer compared to traditional charcoal? Boost Your Furnace Efficiency by 22%

- How does a Zinc Oxide (ZnO) catalyst affect PET pyrolysis? Optimize Yields & Efficiency

- What is the specific function of hydrogen and helium in quartz glass melting? Optimize Your High-Temp Processes

- How do heating and stirring support chemical synthesis? Optimize Reaction Kinetics and Thermodynamics

- Why is electromagnetic induction heating considered environmentally friendly? Zero Emissions & High Efficiency