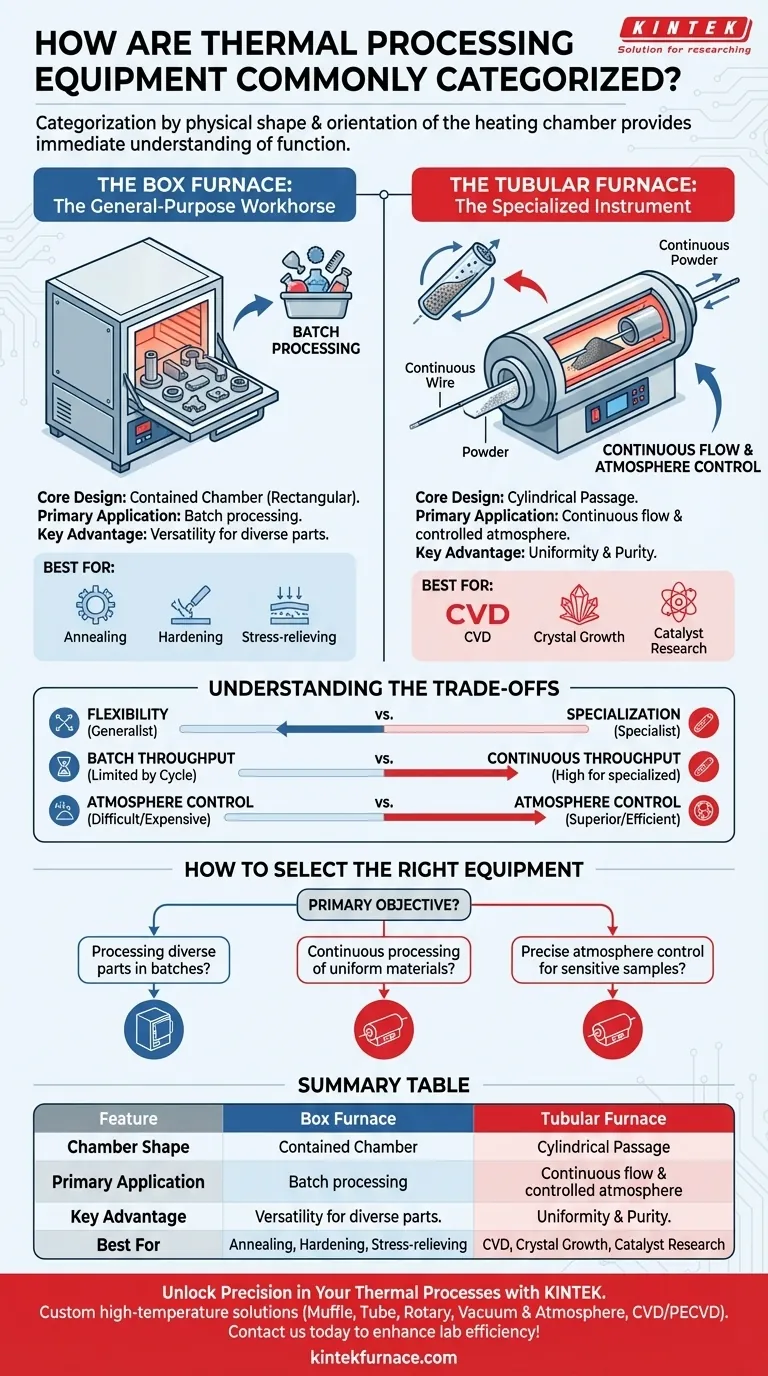

In the field of material science and manufacturing, thermal processing equipment is most commonly categorized by the physical shape and orientation of its heating chamber. This straightforward classification, primarily distinguishing between box furnaces and tubular furnaces, provides an immediate understanding of the equipment's intended function and operational capabilities.

While categorization by shape seems simple, it's a fundamental distinction that dictates the equipment's primary application—from batch processing of diverse parts in a box furnace to the continuous, uniform processing of materials in a tubular furnace.

The Box Furnace: The General-Purpose Workhorse

Box furnaces, also known as muffle furnaces, are defined by their cabinet-like, rectangular heating chamber. This design directly informs their role as versatile tools for batch processing.

The Core Design: A Contained Chamber

A box furnace consists of an insulated chamber, heating elements, and a front-opening door. This simple, accessible design is analogous to a conventional oven, but engineered for much higher temperatures and greater precision.

Primary Application: Batch Processing

The defining use case for a box furnace is batch processing. Materials or parts are placed inside the chamber, the door is closed, and a specific heating and cooling cycle (a "recipe") is executed. Once the cycle is complete, the chamber is opened and the batch is removed.

Key Advantage: Versatility

The open, unrestrictive nature of the chamber allows for the treatment of a wide variety of parts with different shapes and sizes. This makes the box furnace an indispensable tool in research labs, small-scale production, and tool rooms for applications like annealing, hardening, and stress-relieving.

The Tubular Furnace: The Specialized Instrument

A tubular furnace features a cylindrical chamber, typically made of ceramic or a high-temperature metal alloy, around which heating elements are wrapped. This design is optimized for uniformity and controlled environments.

The Core Design: A Cylindrical Passage

Materials are either placed within the tube or passed through it. The enclosed, cylindrical geometry is fundamental to its primary functions.

Primary Application: Continuous Flow and Atmosphere Control

Tubular furnaces excel in two key areas. First, they are ideal for continuous processing of materials like wires, fibers, or powders that can be fed through the tube. Second, their small, easily sealed volume makes them superior for processes requiring a tightly controlled atmosphere (e.g., inert gas like argon or a reactive gas).

Key Advantage: Uniformity and Purity

The cylindrical design naturally promotes excellent temperature uniformity along the central heated zone. This, combined with the ability to easily purge and fill the tube with high-purity gas, makes it the standard for sensitive applications like crystal growth, chemical vapor deposition (CVD), and catalyst research.

Understanding the Trade-offs: Shape Dictates Function

Choosing between a box and a tubular furnace is not about which is "better," but which is correct for the task. The physical design creates inherent advantages and limitations.

Flexibility vs. Specialization

A box furnace is a generalist. It can handle almost any part that fits inside, making it highly flexible. A tubular furnace is a specialist, optimized for uniform samples or processes requiring strict atmosphere control.

Batch Throughput vs. Continuous Throughput

Throughput in a box furnace is limited by the time it takes to complete one full batch cycle. For the right material, a tubular furnace can operate continuously, offering potentially higher throughput for specialized production.

Atmosphere Control

While a box furnace can be modified for a controlled atmosphere, it is difficult and expensive to purge the large volume and maintain gas purity. A tubular furnace achieves superior atmosphere control with less effort and lower gas consumption.

How to Select the Right Equipment for Your Goal

Your process requirements will point directly to the correct equipment category. Consider your primary objective to make a clear decision.

- If your primary focus is processing diverse parts in batches: A box furnace offers the necessary flexibility and accessibility for various shapes and sizes.

- If your primary focus is continuous processing of uniform materials: A tubular furnace is designed for high-throughput, continuous flow applications like treating wires or powders.

- If your primary focus is precise atmosphere control for sensitive samples: A tubular furnace provides the most effective, efficient, and pure environment.

Understanding this fundamental design difference is the first step toward mastering thermal processing.

Summary Table:

| Feature | Box Furnace | Tubular Furnace |

|---|---|---|

| Chamber Shape | Rectangular | Cylindrical |

| Primary Application | Batch processing of diverse parts | Continuous flow and atmosphere control |

| Key Advantage | Versatility for various shapes and sizes | Uniform heating and superior atmosphere purity |

| Best For | Annealing, hardening, stress-relieving | CVD, crystal growth, catalyst research |

Unlock Precision in Your Thermal Processes with KINTEK

Struggling to choose the right furnace for your lab's unique experiments? KINTEK specializes in high-temperature solutions tailored to your needs. Our diverse product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we ensure our equipment precisely meets your specific requirements, whether for batch processing or advanced atmosphere control.

Don't let equipment limitations hold back your research—contact us today to discuss how our advanced furnace solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety