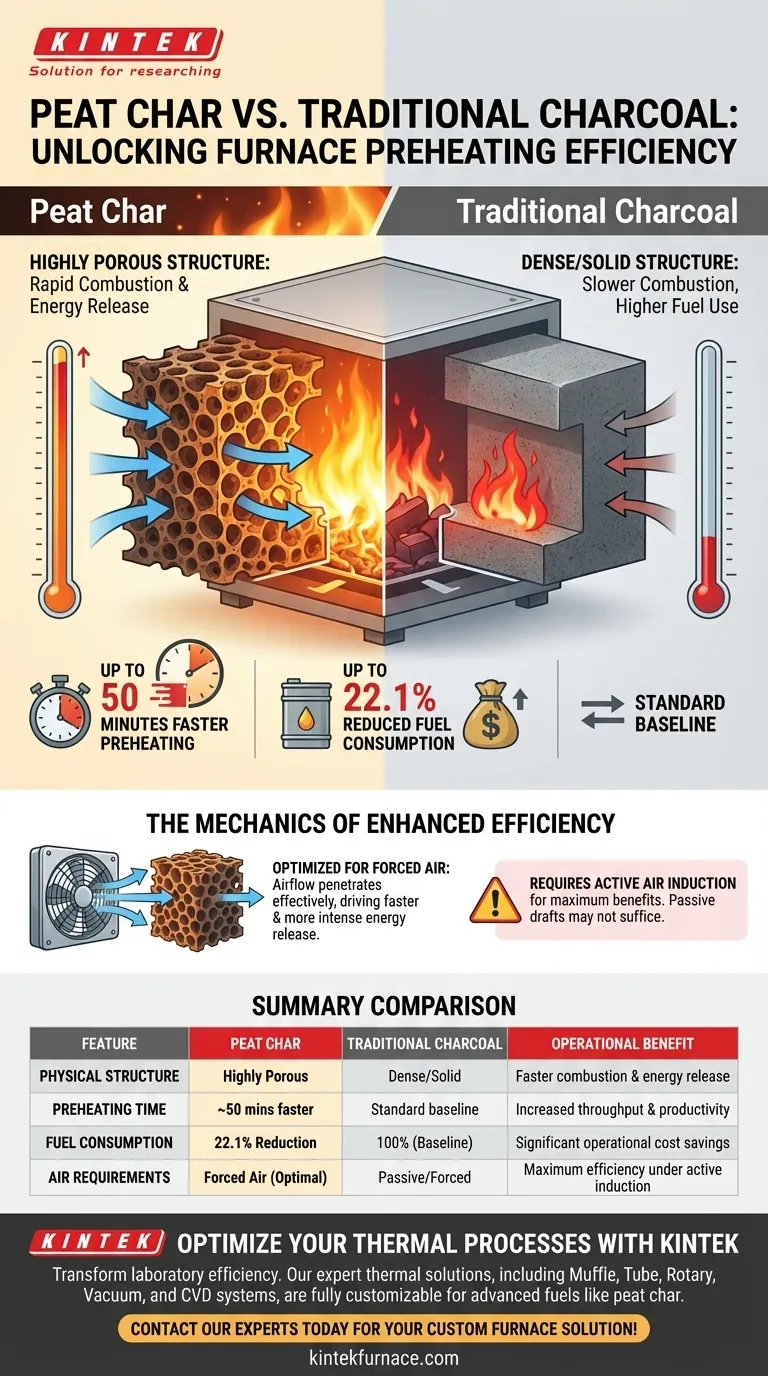

Peat char offers significant operational advantages over traditional charcoal when used for furnace preheating, primarily due to its distinct physical properties. By leveraging its unique porous structure, peat char can accelerate the preheating process to reduce time by approximately 50 minutes and lower overall fuel consumption by up to 22.1 percent.

The superior efficiency of peat char stems from its high porosity, which allows for more rapid combustion and energy release, particularly when utilized under forced air conditions.

The Mechanics of Enhanced Efficiency

The Role of Porosity

The fundamental advantage of peat char lies in its unique porous structure. unlike denser fuels, this structure creates a larger surface area for combustion reactions to occur.

Optimized for Forced Air

This physical characteristic is particularly effective under forced air conditions. The airflow penetrates the porous material more effectively, driving a faster and more intense release of energy compared to traditional charcoal.

Quantifiable Operational Benefits

Accelerated Temperature Rise

In high-temperature furnace applications, time is a critical resource. The rapid combustion of peat char significantly accelerates the rise in temperature.

This acceleration translates to a reduction in preheating times of approximately 50 minutes, allowing operations to reach working temperatures much faster.

Reduced Fuel Consumption

Speed does not come at the cost of efficiency; in this case, they are correlated. Because the furnace reaches temperature more quickly, less total fuel is required for the preheating phase.

Data indicates that using peat char can decrease fuel consumption by up to 22.1 percent, offering a substantial reduction in operational costs.

Understanding the Operational Requirements

The Necessity of Forced Air

While peat char is highly efficient, the primary reference explicitly notes these benefits occur under forced air conditions.

This suggests that to fully realize the rapid temperature rise and fuel savings, the furnace setup must utilize active air induction. Systems relying solely on passive drafts may not exploit the porosity of peat char to the same degree.

Making the Right Choice for Your Goal

When evaluating fuel sources for furnace preheating, consider your specific operational constraints and priorities.

- If your primary focus is rapid turnaround: Switch to peat char to potentially shave nearly an hour off your preheating schedule.

- If your primary focus is cost reduction: Utilize peat char to lower your fuel overhead by roughly 20 percent per cycle.

- If your primary focus is equipment compatibility: Ensure your furnace utilizes forced air induction to maximize the benefits of the char's porous structure.

Leveraging the right fuel structure is the most direct path to optimizing thermal efficiency.

Summary Table:

| Feature | Peat Char | Traditional Charcoal | Operational Benefit |

|---|---|---|---|

| Physical Structure | Highly Porous | Dense/Solid | Faster combustion & energy release |

| Preheating Time | ~50 mins faster | Standard baseline | Increased throughput & productivity |

| Fuel Consumption | 22.1% Reduction | 100% (Baseline) | Significant operational cost savings |

| Air Requirements | Forced Air (Optimal) | Passive/Forced | Maximum efficiency under active induction |

Optimize Your Thermal Processes with KINTEK

Ready to transform your laboratory's efficiency? Whether you are looking to shave an hour off your heating schedule or drastically reduce fuel overhead, choosing the right equipment is vital.

KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our extensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems are fully customizable to handle advanced fuels like peat char, ensuring you maximize every percent of energy efficiency.

Contact our experts today to find your custom furnace solution!

Visual Guide

References

- Paul M. Jack. Feeling the Peat: Investigating peat charcoal as an iron smelting fuel for the Scottish Iron Age. DOI: 10.54841/hm.682

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a pyrolysis device play in the synthesis of porous carbon for supercapacitors? Essential Thermal Secrets

- How does a high-temperature sintering furnace ensure structural integrity? Expert Thermal Management Guide

- What is the purpose of setting an industrial drying oven to 70°C for sludge? Preserve Volatiles & Optimize Pre-treatment

- What is the function of a forced air drying oven for biochar? Optimize Moringa Oleifera Shell Pre-treatment

- What is the function of the nitrogen source in biomass pyrolysis? Optimize Bio-Oil Yield and Ensure Process Safety

- What are the drawbacks of cold compacting and sintering? Higher Porosity and Weaker Mechanical Properties

- What is the significance of calculating AC impedance in the power control of indirect heating resistance furnaces?

- What role does sodium silicate (Na2SiO3) play as a phase transition additive? Optimize Molten Salt Separation