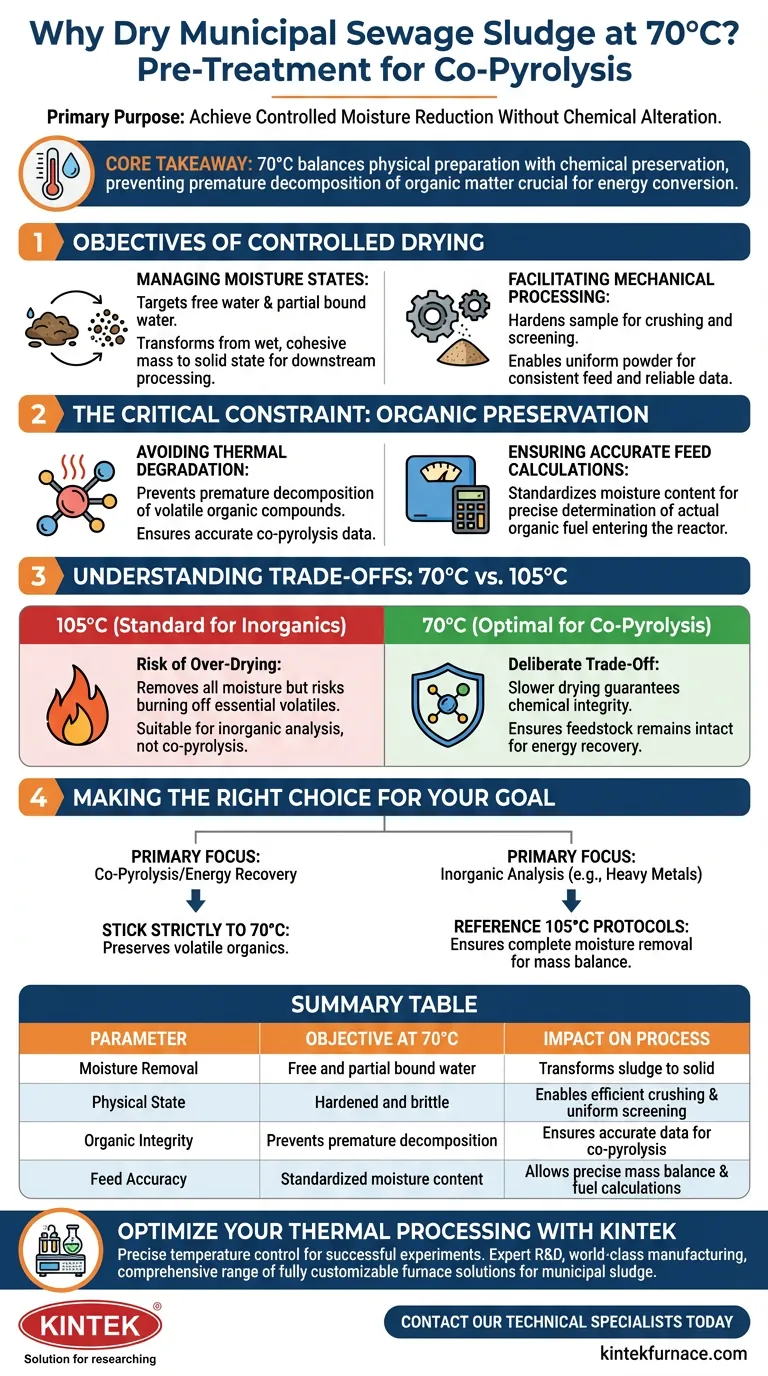

The primary function of setting an industrial drying oven to 70°C during the pre-treatment of municipal sewage sludge is to achieve a controlled reduction of moisture—specifically removing free water and a portion of bound water—without chemically altering the sample. This specific temperature prepares the sludge for mechanical crushing and screening, ensuring the material is physically manageable while preserving the organic components required for accurate co-pyrolysis.

Core Takeaway Drying municipal sewage sludge is a balance between physical preparation and chemical preservation. While higher temperatures remove water faster, 70°C is the specific threshold chosen to prevent the premature decomposition of organic matter, ensuring the feedstock remains chemically intact for subsequent energy conversion processes like co-pyrolysis.

The Objectives of Controlled Drying

Managing Moisture States

The goal at 70°C is not necessarily to achieve the "bone-dry" state used in some analytical chemistry protocols, but rather to remove free water and a specific fraction of bound water.

By targeting these moisture types, the sludge is transformed from a wet, cohesive mass into a solid state. This reduction in volume and stickiness is the foundational step for all downstream physical processing.

Facilitating Mechanical Processing

Wet sludge is difficult to handle; it clumps, smears, and clogs machinery. The 70°C drying phase hardens the sample sufficiently to allow for crushing and screening.

Once dried, the sludge can be ground into a uniform powder. This uniformity is essential for ensuring a consistent feed rate and reliable data during later experimental stages.

The Critical Constraint: Organic Preservation

Avoiding Thermal Degradation

This is the most critical reason for choosing 70°C over the standard 105°C used for other materials. Municipal sewage sludge contains volatile organic compounds that are sensitive to heat.

If the temperature is set too high (e.g., above 100°C), there is a significant risk of premature decomposition of these organic components. If the organics degrade during the drying phase, the data collected during the subsequent co-pyrolysis process will be skewed and inaccurate.

Ensuring Accurate Feed Calculations

For co-pyrolysis (the thermal decomposition of the sludge mixed with other fuels), you must know the precise amount of "actual" fuel entering the reactor.

Drying at 70°C standardizes the moisture content, allowing for an accurate calculation of the feed amount. It removes the variable weight of water without reducing the weight of the organic fuel, ensuring mass balance calculations remain valid.

Understanding the Trade-offs

Temperature vs. Composition

It is common in laboratory settings to use 105°C for drying materials like paper sludge or oil sludge. At 105°C, the objective is the complete removal of all free moisture to establish a dry base for chemical analysis or incineration.

However, this higher temperature is applied to materials where the primary concern is often inorganic analysis (like heavy metals) or where the organic structure is more stable.

The Risk of Over-Drying

Applying the 105°C standard to municipal sewage sludge meant for pyrolysis is a common pitfall.

While it ensures better flowability and total moisture removal, it risks burning off the very volatiles you intend to study. The 70°C setting is a deliberate trade-off: you accept a slower drying process to guarantee the chemical integrity of the sample.

Making the Right Choice for Your Goal

To ensure your pre-treatment aligns with your experimental objectives, consider the following:

- If your primary focus is Co-Pyrolysis/Energy Recovery: Stick strictly to 70°C. This temperature dries the sample sufficiently for grinding while preserving the volatile organics essential for the reaction.

- If your primary focus is Inorganic Analysis (e.g., Heavy Metals): You may reference protocols using 105°C. This ensures complete moisture removal for mass balance, provided organic preservation is not the priority.

Precision in temperature selection is the difference between a dry sample and a chemically altered one.

Summary Table:

| Parameter | Objective at 70°C | Impact on Process |

|---|---|---|

| Moisture Removal | Free and partial bound water | Transforms sludge from cohesive mass to solid |

| Physical State | Hardened and brittle | Enables efficient crushing and uniform screening |

| Organic Integrity | Prevents premature decomposition | Ensures accurate data for subsequent co-pyrolysis |

| Feed Accuracy | Standardized moisture content | Allows for precise mass balance & fuel calculations |

Optimize Your Thermal Processing with KINTEK

Precise temperature control is the difference between a successful experiment and a compromised sample. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique municipal sludge or industrial material needs.

Whether you require delicate drying at 70°C or high-temperature pyrolysis, our equipment ensures the chemical integrity of your feedstock.

Ready to elevate your research accuracy? Contact our technical specialists today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Mahboub Saffari, Rezvan Mashayekhi. The fate and mobility of chromium, arsenic and zinc in municipal sewage sludge during the co-pyrolysis process with organic and inorganic chlorides. DOI: 10.1038/s41598-025-87169-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How do regenerative burners enhance the energy efficiency of billet heating furnaces? Boost Performance by 50%

- How does the extended isothermal calcination in a furnace contribute to crystalline quality? Boost Material Purity

- Why is a laboratory oven required for drying samples at 80°C for MoO3/Ti-Felt? Ensure Electrode Structural Integrity

- Why is the adsorption of dioxins more effective using carbon nanotubes (CNTs)? 3x Superior Efficiency Explained

- What role does an oscillating furnace play in the synthesis of quaternary Ge-Se-Tl-Sb glass alloys? Ensure Homogeneity

- What key data does a Simultaneous Thermal Analyzer (STA) provide for lignite combustion? Assess Fire Risk with Precision

- What are the technical functions of carrier gases in VTD? Master Vapor Transport Deposition Control

- What are the advantages of Flash Lamp Annealing (FLA)? Unlock High-Performance Films on Heat-Sensitive Substrates