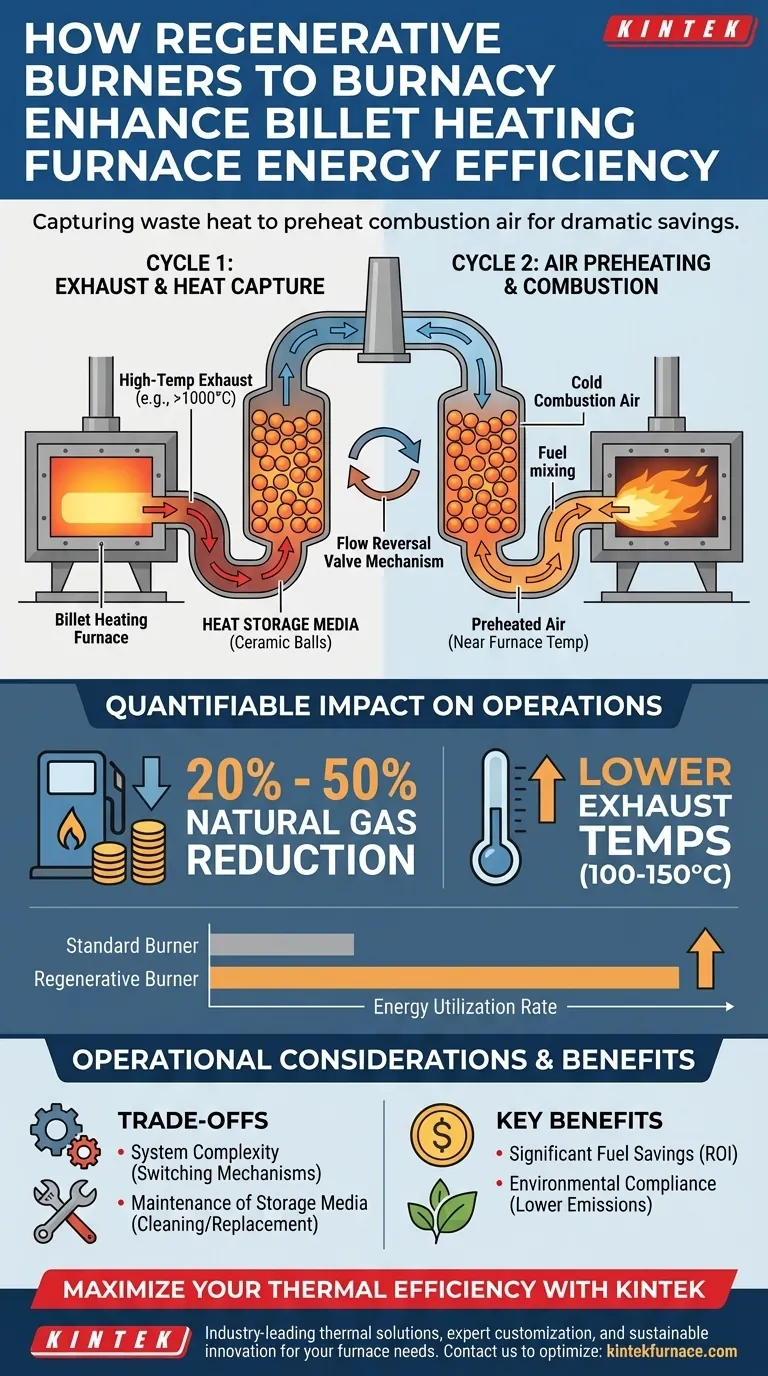

Regenerative burners dramatically improve energy efficiency by capturing the thermal energy typically lost in exhaust gases and recycling it directly back into the combustion process. Through the use of heat storage media, such as ceramic balls, these systems recover sensible heat from flue gases to preheat incoming combustion air, bringing it to temperatures nearly equal to those inside the furnace chamber.

By implementing deep waste heat utilization, regenerative burners can reduce natural gas consumption by 20% to 50% and lower exhaust gas temperatures to a range of 100-150°C, maximizing the heat retained within the furnace.

The Mechanism of Heat Recovery

Utilizing Heat Storage Media

The core of this efficiency lies in the heat storage media, often composed of ceramic balls. These materials possess high thermal capacity, acting as a temporary "battery" for thermal energy.

Capturing Sensible Heat

As high-temperature flue gases exit the furnace, they pass through this bed of storage media. The ceramic material absorbs the sensible heat from the gases, effectively trapping energy that would otherwise be vented into the atmosphere.

Preheating Combustion Air

When the cycle reverses, fresh, cold combustion air is forced through the now-hot ceramic bed. The stored heat is transferred to the air, preheating it to temperatures approaching the furnace's operating temperature before combustion even begins.

Quantifiable Impact on Operations

Significant Fuel Reduction

Because the combustion air enters the burner already hot, significantly less fuel is required to bring the flame to the target temperature. This process leads to a reduction in natural gas consumption by 20% to 50%, depending on the specific furnace conditions.

Lowering Exhaust Temperatures

A clear indicator of this system's efficiency is the temperature of the gas finally exiting the stack. Regenerative burners reduce exhaust gas temperatures to a range of 100-150°C.

Increased Energy Utilization Rates

This low exhaust temperature confirms that the vast majority of thermal energy generated has been extracted and kept within the system. This results in a drastic increase in the facility's overall energy utilization rate.

Operational Considerations and Trade-offs

System Complexity

While efficient, regenerative systems are mechanically more complex than standard burners. They require reliable switching mechanisms to cycle air and exhaust flows through the media beds.

Maintenance of Storage Media

The ceramic balls or media can accumulate particulates or degrade over time. Regular inspection is required to ensure airflow remains unobstructed and heat transfer remains efficient.

Making the Right Choice for Your Goal

Implementing regenerative burners is a significant capital improvement that yields long-term operational savings.

- If your primary focus is Operating Cost Reduction: Expect a direct correlation between installation and a 20-50% drop in fuel bills, providing a clear ROI calculation.

- If your primary focus is Environmental Compliance: Leverage the reduced exhaust temperatures (100-150°C) to lower thermal pollution and decrease your facility's overall carbon footprint.

Adopting regenerative technology transforms waste heat from a byproduct into a valuable asset, fundamentally changing the economics of billet heating.

Summary Table:

| Key Performance Metric | Regenerative Burner Impact |

|---|---|

| Fuel Savings | 20% - 50% reduction in natural gas |

| Exhaust Gas Temp | Lowered to 100-150°C |

| Preheat Method | Ceramic ball heat storage media |

| Primary Benefit | Deep waste heat recovery & utilization |

| Key Component | Ceramic thermal storage beds |

Maximize Your Thermal Efficiency with KINTEK

Ready to transform your furnace operations? KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you need specialized Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temp furnaces are fully customizable to meet your unique processing needs.

Why choose KINTEK?

- Drastic Cost Reduction: Lower fuel consumption and operational overhead.

- Expert Customization: Tailored high-temp systems for specific industrial and lab applications.

- Sustainable Innovation: Reduce your carbon footprint with advanced heat recovery technology.

Don't let valuable energy escape through the stack. Contact us today to optimize your heating process!

Visual Guide

References

- M.V. Hubynskyi, D.Yu. Uhriumov. ENERGY-SAVING TECHNOLOGIES IN PIPE PRODUCTION. DOI: 10.34185/1991-7848.2025.01.20

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a forced air drying oven for NAB alloys? Essential Prep for High-Purity Nickel-Aluminum Bronze

- What is the function of zone melting purification equipment in the preparation of CsPbBr3 perovskite single crystals? Key for 6N.

- What is the importance of a laboratory oven's programmed heating for epoxy-polyimide curing? Essential Thermal Control

- What is the role of high-purity argon gas in ultrafine magnesium powder production? Control Particle Size & Purity

- What are the advantages of using a vacuum drying oven for precursors on carbon paper? Maximize Material Performance

- What is the basic principle of a sintering furnace? Transform Powder into Dense, Strong Components

- How does Faraday's Law of Induction work in induction heating? Achieve Precise, Non-Contact Thermal Processing

- Why is a forced convection oven necessary in the powder preparation workflow? Optimize Your Thermoelectric Materials