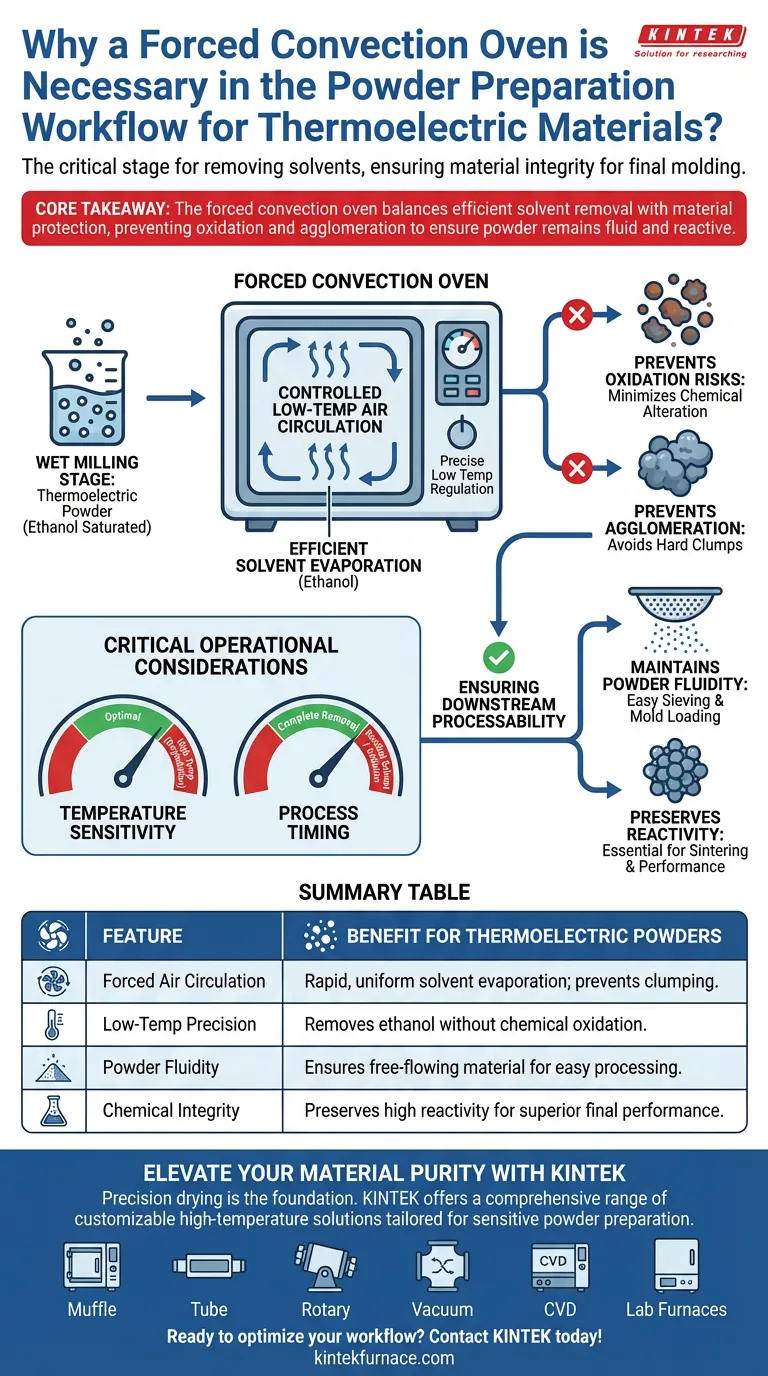

A forced convection oven is the critical mechanism for removing solvents, such as ethanol, following the wet milling stage of thermoelectric powder preparation. By utilizing controlled, low-temperature air circulation, it ensures the complete evaporation of liquids without compromising the powder's chemical integrity or physical consistency.

Core Takeaway: The forced convection oven balances efficient solvent removal with material protection. It prevents the two biggest risks during drying—oxidation and agglomeration—ensuring the powder remains fluid and reactive for the final molding process.

The Role of Controlled Drying in Processing

Efficient Solvent Removal

After wet milling, thermoelectric powders are saturated with solvents like ethanol. You cannot proceed to molding until this liquid is entirely removed.

A forced convection oven circulates hot air to accelerate evaporation. This ensures the drying process is both rapid and uniform throughout the batch.

Controlled Low Temperatures

Speed cannot come at the cost of material degradation. These ovens allow for precise temperature regulation.

By operating at low temperatures, the oven removes the solvent without subjecting the material to excessive heat. This protects the fundamental properties of the thermoelectric compound.

Preventing Material Degradation

Minimizing Oxidation Risks

Thermoelectric materials can be highly sensitive to environmental factors. Exposure to high heat in an uncontrolled environment often leads to oxidation.

Oxidation alters the chemical reactivity of the powder. The forced convection oven mitigates this risk by drying the powder gently, preserving its chemical purity for the next stages of fabrication.

Preventing Agglomeration

When powders dry unevenly or slowly, particles tend to stick together. This creates hard clumps, or agglomerates, which are difficult to process.

The constant circulation of air prevents moisture pockets from lingering. This ensures the particles dry individually rather than fusing into a solid cake.

Ensuring Downstream Processability

Maintaining Powder Fluidity

The steps following drying are sieving and mold loading. Both require the material to behave like a fluid.

Because the oven prevents clumping, the resulting powder remains free-flowing. This "fluidity" allows the powder to pass easily through sieves and fill molds evenly.

Preserving Reactivity

The physical state of the powder dictates how well it sinters or forms during molding.

By avoiding oxidation and agglomeration, the oven ensures the powder maintains high chemical reactivity. This is essential for achieving the desired thermoelectric performance in the final solid component.

Critical Operational Considerations

Temperature Sensitivity

While the oven is designed to prevent oxidation, operator settings are crucial. Even with forced convection, setting the temperature too high can negate the protective benefits and degrade the material.

Process Timing

The goal is to remove ethanol completely. Removing the powder too early leaves residual solvent, which can cause defects during molding. Leaving it too long at temperature may eventually introduce oxidation risks.

Making the Right Choice for Your Goal

To maximize the quality of your thermoelectric materials, align your drying parameters with your specific processing needs.

- If your primary focus is material purity: Keep the oven temperature low to ensure the ethanol evaporates without triggering chemical oxidation.

- If your primary focus is handling efficiency: rely on the uniform air circulation to prevent agglomeration, ensuring the powder is immediately ready for sieving without additional grinding.

The forced convection oven is not just a drying tool; it is a preservation stage that bridges wet processing and final consolidation.

Summary Table:

| Feature | Benefit for Thermoelectric Powders |

|---|---|

| Forced Air Circulation | Rapid, uniform solvent evaporation and prevention of particle clumping (agglomeration). |

| Low-Temp Precision | Removes ethanol/solvents without reaching temperatures that cause chemical oxidation. |

| Powder Fluidity | Ensures dried material remains free-flowing for easy sieving and mold loading. |

| Chemical Integrity | Preserves high chemical reactivity for superior sintering and final performance. |

Elevate Your Material Purity with KINTEK

Precision drying is the foundation of high-performance thermoelectric materials. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab furnaces tailored for sensitive powder preparation.

Whether you need to eliminate oxidation or ensure uniform particle consistency, our customizable high-temperature solutions provide the control your research demands.

Ready to optimize your workflow? Contact KINTEK today to find the perfect furnace for your unique needs!

Visual Guide

References

- Effect of Sb Doping on the Thermoelectric Properties of MNiSn (M=Ti, Zr, Hf) Half-Heusler Alloys Fabricated by a Rapid Solidification Process. DOI: 10.3365/kjmm.2025.63.4.243

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the role of an industrial high-speed ball mill in kaolin pretreatment? Enhance Reactivity & Surface Area

- What are the complexities and maintenance requirements of continuous furnaces? Optimize High-Volume Production with Expert Insights

- What are the primary technical objectives of CoCrFeMnNi alloy annealing? Master Recrystallization & Phase Control

- Why is a homogeneous reactor used for crystallization? Achieve 100% Thermal Uniformity for Pure Crystals

- What is the function of a laboratory drying oven in processing NdFeB waste? Ensure Purity in Rare Earth Recovery

- What technical advantages does a custom high-temperature furnace provide for in-situ diffraction on molten sulfur?

- What role does precise temperature control play in nuclear waste leaching tests? Ensure Accurate Safety Evaluations

- How does the buried-sintering method affect BCZT ceramics performance? Optimize Your Sintering for Peak Piezoelectricity