The buried-sintering method significantly degrades the piezoelectric performance of (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 (BCZT) ceramics when compared to exposed-sintering. While standard sintering relies on high temperatures to densify the material, burying the sample in compact BCZT powder creates an oxygen-deficient environment that fundamentally alters the material's defect chemistry, leading to reduced polarization and piezoelectric capability.

Core Takeaway Buried-sintering acts as a barrier to oxidation, artificially increasing the concentration of oxygen vacancies within the ceramic. This results in a "hardening" effect that stabilizes the material but directly causes a significant decrease in the piezoelectric coefficient ($d_{33}$) and polarization intensity.

The Mechanism of Buried Sintering

Limiting Atmospheric Interaction

In the buried-sintering method, BCZT samples are completely embedded within compact BCZT powder.

This physical barrier isolates the samples from the ambient atmosphere inside the furnace.

Inhibition of Oxidation

The primary consequence of this isolation is the inhibition of the oxidation process.

Unlike exposed-sintering, where the material interacts freely with air, the buried samples are starved of the oxygen necessary to maintain ideal stoichiometry during the high-heat phase.

Impact on Defect Chemistry

Increased Oxygen Vacancies

Because the oxidation process is inhibited, the chemical balance of the ceramic shifts.

This environment promotes a higher concentration of oxygen vacancies within the crystal lattice.

The Consequence of Defects

These vacancies are not benign; they act as defects that alter how the material responds to electrical fields.

High concentrations of oxygen vacancies are the root cause of the performance shifts observed in buried samples.

Performance Outcomes: The "Hardening" Effect

Reduced Piezoelectric Coefficient ($d_{33}$)

The most critical drawback of the buried method for BCZT is a significant decrease in the piezoelectric coefficient ($d_{33}$).

For applications requiring high sensitivity or strong electromechanical coupling, buried-sintering is detrimental.

Lower Polarization Intensity

The oxygen vacancies likely pin domain walls, restricting their movement.

This restriction manifests as reduced polarization intensity, making the material less responsive to external electric fields compared to exposed-sintered samples.

Material Hardening

The combination of increased oxygen vacancies and reduced domain mobility results in "material hardening."

While "hard" ferroelectrics can have lower losses, in this specific context, the hardening comes at the expense of the material's primary functional properties (piezoelectricity).

Understanding the Trade-offs

Kinetics vs. Chemistry

Standard sintering requires temperatures between 1300°C and 1500°C to ensure proper grain growth and pore elimination.

However, even if the furnace provides perfect kinetic conditions and temperature uniformity, the chemical atmosphere dictates the final performance.

The Cost of Isolation

Buried sintering might seem like a protective measure, but it introduces a chemical deficit.

By preventing the material from "breathing" (oxidizing), you trade potential surface protection for a significant loss in functional performance.

Making the Right Choice for Your Goal

Based on the impact of oxygen vacancies on BCZT performance, here is how you should approach your sintering strategy:

- If your primary focus is maximizing piezoelectricity ($d_{33}$): Avoid buried-sintering; use exposed-sintering to ensure full oxidation and minimize oxygen vacancies.

- If your primary focus is material hardening: Buried-sintering can be utilized to intentionally introduce oxygen vacancies, though you must accept the trade-off of lower polarization.

To achieve peak piezoelectric performance in BCZT ceramics, you must prioritize an oxygen-rich sintering environment over the isolation provided by powder embedding.

Summary Table:

| Feature | Exposed Sintering (Recommended) | Buried Sintering (Deficient) |

|---|---|---|

| Oxygen Access | High (Open atmosphere) | Low (Inhibited oxidation) |

| Oxygen Vacancies | Low (Ideal stoichiometry) | High (Defect-prone) |

| $d_{33}$ Coefficient | Superior (High sensitivity) | Significant decrease |

| Polarization | High intensity | Reduced (Domain pinning) |

| Material State | Optimized functional properties | "Hardened" (Lower performance) |

Unlock High-Performance Ceramic Processing with KINTEK

Don't let improper sintering atmospheres compromise your BCZT ceramic quality. At KINTEK, we understand that precise atmospheric control is just as critical as temperature uniformity.

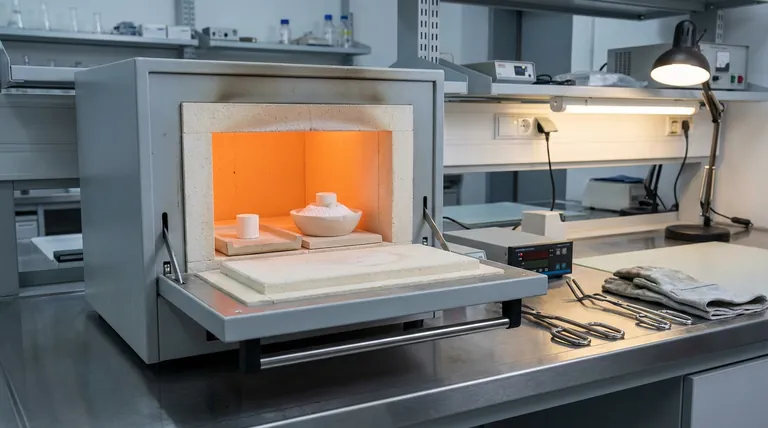

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temperature furnaces, including:

- Muffle Furnaces for standard exposed-sintering.

- Vacuum and CVD Systems for precise atmospheric manipulation.

- Tube and Rotary Furnaces for versatile thermal processing.

- Customizable Systems tailored to your unique research or production needs.

Ensure your materials reach their maximum piezoelectric potential with our industry-leading thermal solutions. Contact our technical experts today to find the perfect furnace for your laboratory.

References

- Zihe Li, Chris Bowen. Porous Structure Enhances the Longitudinal Piezoelectric Coefficient and Electromechanical Coupling Coefficient of Lead‐Free (Ba<sub>0.85</sub>Ca<sub>0.15</sub>)(Zr<sub>0.1</sub>Ti<sub>0.9</sub>)O<sub>3</sub>. DOI: 10.1002/advs.202406255

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How do industrial heat treatment furnaces ensure 55Si2 spring steel stability? Optimize Your Tempering Process

- Why is it necessary to use a vacuum drying oven for porous graphene cathodes? Ensure Peak Battery Performance

- How does a PID intelligent segmented temperature control system impact diamond tools? Precision Sintering Explained

- Why are DEZ and GEME selected for Ge:ZnO ALD? Unlock Precise Atomic Doping and Thermal Stability

- Why must Sm:YAG ceramics undergo air annealing? Restoring Optical Clarity and Restructuring Defects

- What is the significance of using a high-precision gas mass flow controller for hydrogen flow? | Master Uniform Thermal Reduction

- What role does graphite paper play in magnesium vapor condensation experiments? A Key to High-Purity Collection & Analysis

- What is the purpose of using a laboratory drying oven for catalyst recycling? Optimize Performance & Data Integrity