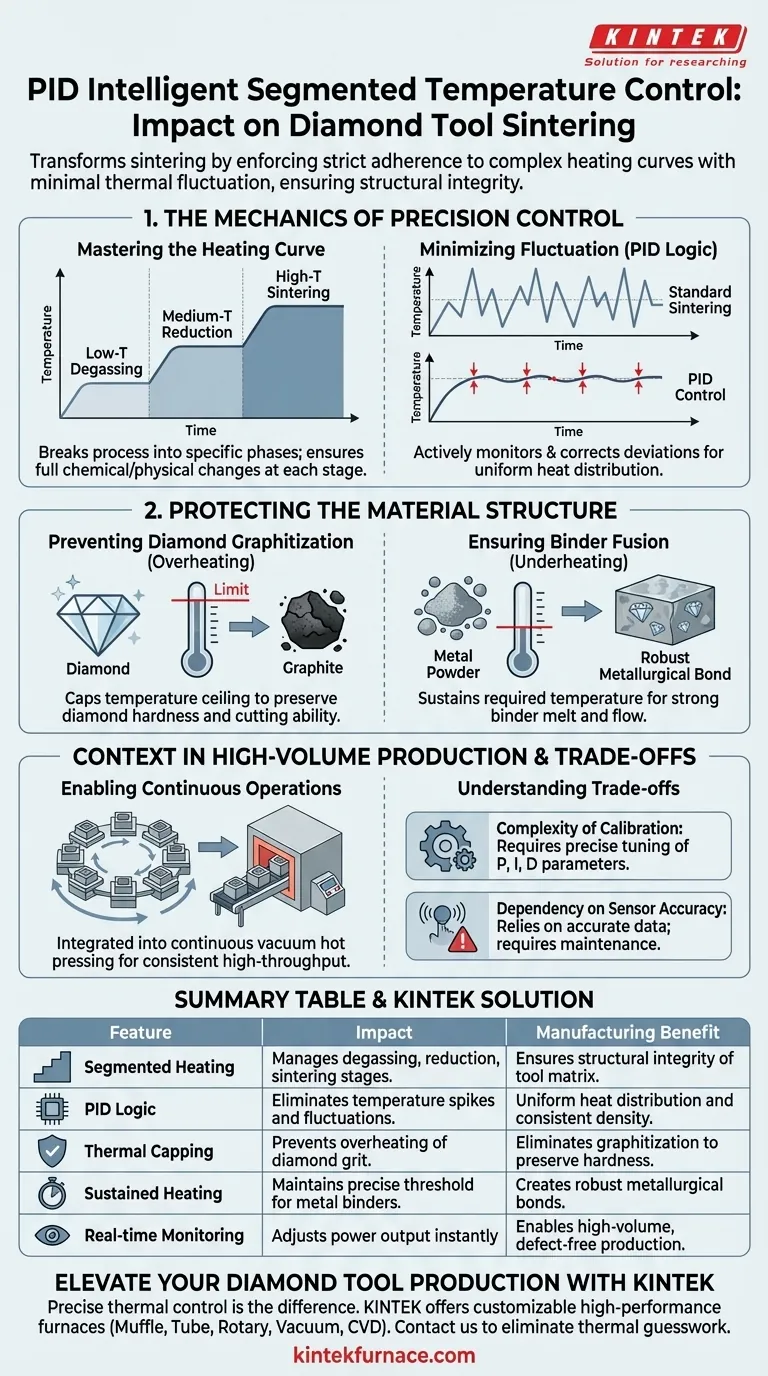

A PID intelligent segmented temperature control system fundamentally transforms the sintering process by enforcing strict adherence to complex heating curves with minimal thermal fluctuation. This technology allows for the precise management of distinct processing stages—low-temperature degassing, medium-temperature reduction, and high-temperature sintering—ensuring the structural integrity of the final diamond tool.

The core value of this system lies in its ability to eliminate the "thermal guess-work" that leads to product failure. By preventing both overheating (which destroys diamonds) and underheating (which results in weak bonding), it guarantees consistent density and performance across production batches.

The Mechanics of Precision Control

Mastering the Heating Curve

Standard temperature controllers often treat heating as a single linear event. A segmented PID system breaks the process down into specific phases.

It automatically adjusts power output to accommodate the specific requirements of low-temperature degassing, medium-temperature reduction, and high-temperature sintering. This ensures the chemical and physical changes required at each stage occur fully before moving to the next.

Minimizing Temperature Fluctuation

In standard sintering, temperature spikes are common. PID (Proportional-Integral-Derivative) logic actively monitors and corrects these deviations in real-time.

By keeping temperature fluctuations to a minimum, the system ensures uniform heat distribution within the mold. This stability is the difference between a high-grade professional tool and a defective product.

Protecting the Material Structure

Preventing Diamond Graphitization

The most critical risk in diamond tool manufacturing is "over-burning." If the temperature spikes too high, the diamond particles can degrade into graphite.

Graphitization renders the diamond useless as a cutting agent. PID control caps the temperature ceiling precisely, preserving the hardness and cutting ability of the diamond grit.

Ensuring Binder Fusion

Conversely, "under-burning" occurs when the temperature fails to reach the necessary threshold for the metal binder to melt and flow.

If the binder does not fuse correctly, it cannot hold the diamond particles securely. The PID system ensures the sintering temperature is reached and sustained long enough to create a robust metallurgical bond.

Context in High-Volume Production

Enabling Continuous Operations

While the PID system handles the heat, it is often integrated into multi-station continuous vacuum hot pressing equipment.

These systems use a rotating table to synchronize loading, heating, and pressing in a pipeline operation. The PID controller ensures that as molds move rapidly between stations, the thermal profile remains consistent, enabling the production of tens of thousands of units annually without quality variation.

Understanding the Trade-offs

Complexity of Calibration

While highly effective, PID systems require precise tuning. If the Proportional, Integral, and Derivative parameters are not calibrated correctly for the specific thermal mass of the mold, the system can still oscillate or react too slowly.

Dependency on Sensor Accuracy

The "intelligence" of the system is only as good as its data. These systems rely heavily on thermocouples or pyrometers.

If a sensor drifts or fails, the PID logic will execute perfectly based on bad data, leading to a batch of ruined tools. Regular sensor maintenance is mandatory to maintain the system's value.

Making the Right Choice for Your Manufacturing

To maximize the benefits of intelligent temperature control, align your equipment settings with your specific production goals:

- If your primary focus is Maximum Tool Life: Prioritize the precision of the high-temperature sintering stage to prevent even microscopic graphitization of the diamonds.

- If your primary focus is High Throughput: Focus on the system's recovery time, ensuring the controller can stabilize temperatures instantly as the multi-station table rotates new molds into the heating zone.

True process control is not just about getting hot; it is about applying the exact amount of energy needed to forge a bond without compromising the abrasive.

Summary Table:

| Feature | Impact on Diamond Tool Sintering | Manufacturing Benefit |

|---|---|---|

| Segmented Heating | Manages degassing, reduction, and sintering stages | Ensures structural integrity of the tool matrix |

| PID Logic | Eliminates temperature spikes and fluctuations | Uniform heat distribution and consistent density |

| Thermal Capping | Prevents overheating of diamond grit | Eliminates graphitization to preserve hardness |

| Sustained Heating | Maintains precise threshold for metal binders | Creates robust metallurgical bonds and retention |

| Real-time Monitoring | Adjusts power output instantly during rotation | Enables high-volume, defect-free production |

Elevate Your Diamond Tool Production with KINTEK

Precise thermal control is the difference between a high-grade tool and a defective product. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique sintering requirements.

Whether you are aiming for maximum tool life through precise high-temperature control or high throughput with multi-station automation, our advanced lab and industrial furnaces provide the stability your materials demand.

Ready to eliminate thermal guesswork? Contact KINTEK today to discuss your custom furnace solutions!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What role does natural zeolite play as a catalyst in LDPE pyrolysis? Boost Yield and Efficiency in Plastic Recycling

- What are the advantages of solution combustion synthesis? Optimize (MnFeNiCoX)3O4 High-Entropy Oxide Catalyst Production

- Why is a high-purity argon flow required during the thermal reduction of nitrogen-doped graphene oxide?

- How does a heated substrate platform mitigate the coffee ring effect? Enhance Ag2Se Printing Precision

- What is the role of high-purity helium in electromagnetic levitation? Key for Rapid Thermal Regulation

- Why is a constant flow of CO2 maintained during biochar pyrolysis? Unlock Precision Material Engineering

- How does a precision pressure-controlled oxidation device increase carbon chain yield? Optimize Your Annealing Process

- What is the function of a vacuum drying oven in CMS synthesis? Ensure High-Purity Precursor Integrity