Precise temperature control equipment serves as the stabilizing foundation for nuclear waste leaching tests. Its primary function is to maintain an exact, constant temperature—often around 90°C—over extended periods of time. This consistency is mandatory to accurately simulate the environmental conditions of groundwater erosion that occur in underground storage sites.

Reliable temperature regulation transforms a simple chemical test into a robust simulation of geological reality. By strictly maintaining thermal constants, researchers can distinguish the true chemical durability of a waste matrix from environmental noise, ensuring that safety assessments are based on accurate release rate data.

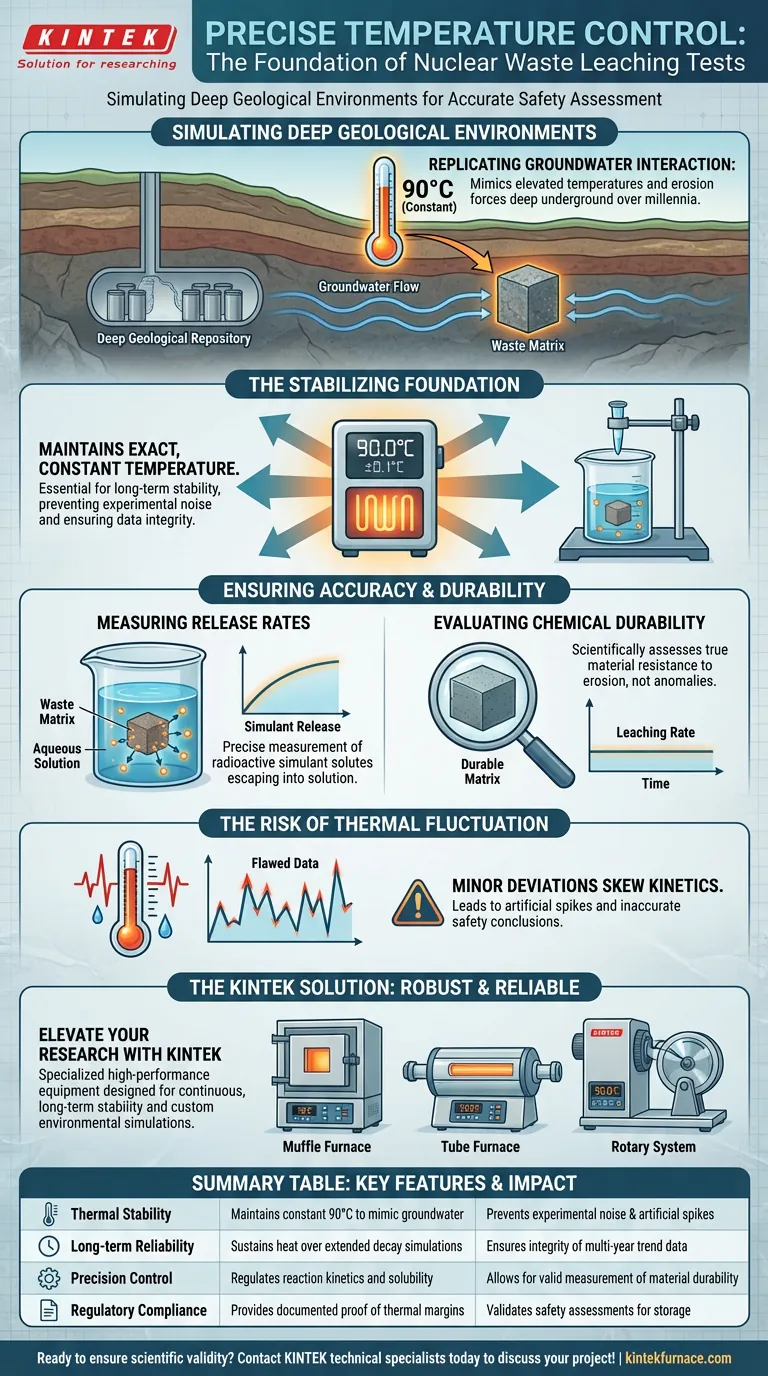

Simulating Deep Geological Environments

To predict how nuclear waste will behave over thousands of years, researchers must replicate the specific conditions of its final resting place.

Replicating Groundwater Interaction

Deep underground, waste matrices are exposed to groundwater at elevated temperatures.

Precise equipment allows scientists to mimic this thermal environment, such as a sustained 90°C. This ensures the test faithfully represents the erosion forces the matrix will face in a real-world repository.

The Necessity of Long-Term Stability

Nuclear waste decay is a slow process, and safety evaluations must look far into the future.

These tests run over long durations to capture meaningful trend data. The temperature control equipment must operate without failure or fluctuation throughout this period to maintain the integrity of the simulation.

Ensuring Data Accuracy and Chemical Durability

The core purpose of the test is to measure how radioactive materials escape the waste matrix.

Measuring Release Rates

Researchers analyze how quickly radioactive simulants act as solutes, moving from the solid matrix into the surrounding aqueous solution.

Temperature control allows for the precise measurement of these release rates. Because solubility and reaction rates are temperature-dependent, stable heat is crucial for valid measurements.

Evaluating Chemical Durability

The ultimate goal is a scientific evaluation of the matrix's chemical durability.

If the temperature varies, the leaching rate changes, making it impossible to judge the material's quality. Steady temperature ensures that the data reflects the matrix's actual resistance to erosion, rather than experimental anomalies.

Understanding the Trade-offs

While high-precision equipment is essential, it introduces specific operational demands that must be managed to avoid data corruption.

The Risk of Thermal Fluctuation

Even minor deviations in temperature can drastically skew reaction kinetics.

If the equipment fails to hold the set point, the release rate of simulants may spike or drop artificially. This leads to flawed conclusions regarding the safety of the waste form.

Complexity vs. Reliability

Maintaining a specific temperature like 90°C indefinitely requires robust hardware.

Standard laboratory ovens may not suffice for these rigorous protocols. Specialized equipment designed for continuous, long-term operation is required to prevent drift and ensure the scientific validity of the evaluation.

Making the Right Choice for Your Evaluation

When selecting equipment or designing protocols for leaching tests, aligning your tools with your data requirements is critical.

- If your primary focus is regulatory compliance: Ensure your equipment can document and prove thermal stability within a tight margin of error over the entire test duration.

- If your primary focus is material development: Prioritize equipment that allows you to easily adjust and hold different temperature set points to stress-test the matrix under various theoretical conditions.

Precise temperature control is not merely a feature; it is the control variable that makes the scientific evaluation of nuclear waste safety possible.

Summary Table:

| Key Feature | Role in Leaching Tests | Impact on Data Accuracy |

|---|---|---|

| Thermal Stability | Maintains constant 90°C to mimic groundwater | Prevents experimental noise & artificial spikes |

| Long-term Reliability | Sustains heat over extended decay simulations | Ensures integrity of multi-year trend data |

| Precision Control | Regulates reaction kinetics and solubility | Allows for valid measurement of material durability |

| Regulatory Compliance | Provides documented proof of thermal margins | Validates safety assessments for repository storage |

Elevate Your Radioactive Waste Research with KINTEK

Precise thermal management is the cornerstone of reliable nuclear safety assessments. At KINTEK, we understand that even a minor temperature drift can compromise years of research. Backed by expert R&D and manufacturing, we offer a comprehensive range of high-performance lab equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—specifically designed to maintain the rigorous stability required for leaching and durability tests.

Whether you are conducting regulatory compliance checks or developing next-generation waste matrices, our systems are fully customizable to meet your unique environmental simulation needs.

Ready to ensure the scientific validity of your thermal evaluations? Contact our technical specialists today to discuss your project requirements!

Visual Guide

References

- S. V. Yudintsev, V. I. Malkovsky. Thermal Effects and Glass Crystallization in Composite Matrices for Immobilization of the Rare-Earth Element–Minor Actinide Fraction of High-Level Radioactive Waste. DOI: 10.3390/jcs8020070

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why are rotary evaporators or industrial ovens recommended for handling Boron Carbide mixed slurries containing solvents?

- What is the purpose of using an industrial-grade oven for segmented drying? Optimize Electrode Integrity & Adhesion

- What is the primary purpose of operating a laboratory oven at 383 K for 24 hours? Precision Drying for Carbon Prep

- What is the significance of programmed temperature control in TiO2 thin film conversion? Master Structural Precision

- Why is precise temperature control essential for aluminum alloy solidification? Unlock Superior Material Strength

- What is the purpose of using a thermal evaporation coating system? Enhancing I-V Testing Accuracy for Nanocomposites

- What are the complexities and maintenance requirements of continuous furnaces? Optimize High-Volume Production with Expert Insights

- What role does a high-performance blast drying oven play in the hydrothermal reaction stage of CoO/CoSe nanoparticles?