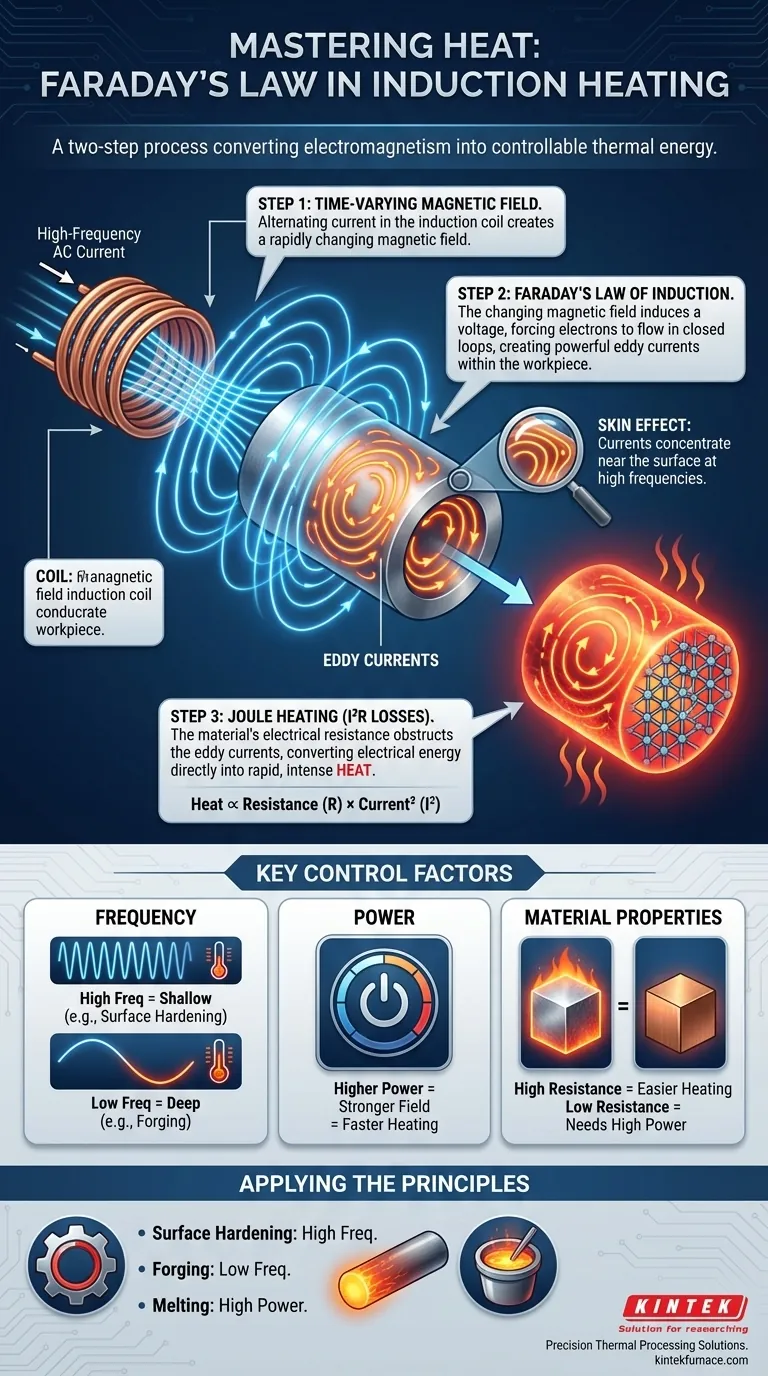

In essence, induction heating works because of a two-step process initiated by Faraday's Law. First, a rapidly changing magnetic field is used to induce powerful electrical currents, called eddy currents, directly within a conductive part. Second, the material's natural electrical resistance obstructs these currents, causing immense friction at an atomic level, which instantly generates clean, controllable heat.

Induction heating translates the principles of electromagnetism into thermal energy. It uses a magnetic field as a medium to generate electrical currents inside a target material, and then leverages that material's own resistance to turn those currents into heat.

The Core Principle: From Magnetism to Current

Induction heating is a non-contact method that begins with generating a specific type of magnetic field. The process is governed by fundamental laws of physics.

Step 1: Creating a Time-Varying Magnetic Field

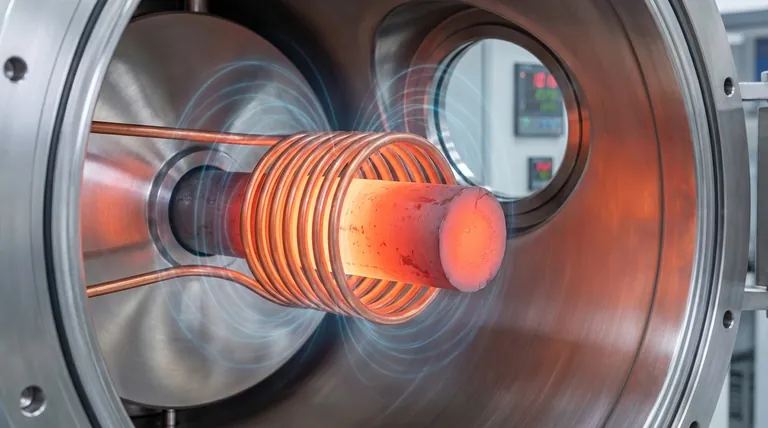

The process starts with an induction coil, typically made of copper tubing. A high-frequency alternating current (AC) is passed through this coil.

This AC current produces a highly concentrated and rapidly changing magnetic field in the space around and within the coil.

Step 2: Faraday's Law of Induction

When a conductive workpiece (like a piece of steel) is placed inside this magnetic field, the field lines pass through it.

Because the magnetic field is alternating, its strength and direction are constantly changing. According to Faraday's Law of Induction, this change induces a voltage, or electromotive force, within the workpiece.

Step 3: The Birth of Eddy Currents

This induced voltage forces electrons to flow within the conductive material. Because the workpiece is a solid object, these currents swirl in closed loops.

These swirling, internal currents are known as eddy currents. They are the direct result of Faraday's Law acting on the workpiece.

The Mechanism of Heating: From Current to Heat

The creation of eddy currents is only half the story. The actual heating comes from the interaction of these currents with the material itself.

The Role of Electrical Resistance

No material is a perfect conductor; every metal has some degree of electrical resistance. This resistance acts like friction to the flow of electrons.

As the powerful eddy currents are forced to flow through the resistive metal, they overcome this "friction," and the electrical energy is converted directly into thermal energy.

Joule Heating (I²R Losses)

This phenomenon is known as Joule heating. The amount of heat produced is directly proportional to the material's resistance (R) and the square of the current's magnitude (I²).

Because the induced eddy currents can be very large, the resulting I²R losses generate rapid and intense heat precisely where the currents are flowing.

The Skin Effect

At the high frequencies used in induction heating, the eddy currents do not flow uniformly through the part. They tend to concentrate in a thin layer near the surface.

This is called the skin effect. It causes the surface of the part to heat up much more rapidly and intensely than its core, making induction heating ideal for applications like surface hardening.

Understanding the Key Factors

The effectiveness and nature of induction heating are not random. They are controlled by several key parameters that an engineer can manipulate.

Impact of Frequency

The frequency of the alternating current is a critical control lever. Higher frequencies create a stronger skin effect, concentrating the heat on the surface for shallow, rapid heating. Lower frequencies allow the magnetic field to penetrate deeper, heating more of the material's volume.

Impact of Power

The power applied to the induction coil determines the strength of the magnetic field. A stronger field induces a higher voltage, which in turn creates larger eddy currents and generates heat more quickly.

Impact of Material Properties

The material of the workpiece plays a huge role. Materials with higher electrical resistance (like steel or titanium) heat up much more easily than materials with low resistance (like copper or aluminum). Magnetic materials like steel also benefit from hysteresis heating at lower temperatures, which adds to the overall effect.

Making the Right Choice for Your Application

Understanding these principles allows you to precisely control the heating process for different industrial goals.

- If your primary focus is surface hardening a steel gear: Use a high frequency (50 kHz to 400 kHz) to concentrate the heat in a thin layer on the teeth, followed by a rapid quench.

- If your primary focus is heating a large billet for forging: Use a lower frequency (1 kHz to 10 kHz) to ensure the heat penetrates deep into the material's core for uniform malleability.

- If your primary focus is melting a highly conductive metal like copper: You must use a very high-power system to generate a magnetic field strong enough to induce significant heating currents.

By mastering these electromagnetic principles, you can apply heat with surgical precision, exactly when and where it is needed.

Summary Table:

| Principle | Role in Induction Heating |

|---|---|

| Faraday's Law | Induces voltage and eddy currents in a conductive workpiece. |

| Joule Heating (I²R Losses) | Converts electrical energy from eddy currents into heat. |

| Skin Effect | Concentrates heat at the surface for precise thermal control. |

| Frequency | Controls the depth of heat penetration (high for surface, low for deep). |

Master precise thermal processing with KINTEK's advanced induction heating solutions.

Understanding the principles of electromagnetic induction is the first step. Applying them with the right equipment is what delivers results. KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions.

Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements—whether you are surface hardening, forging, or melting.

Ready to harness the power of induction heating with surgical precision? Contact our experts today to discuss how we can tailor a solution for your specific material and application.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications