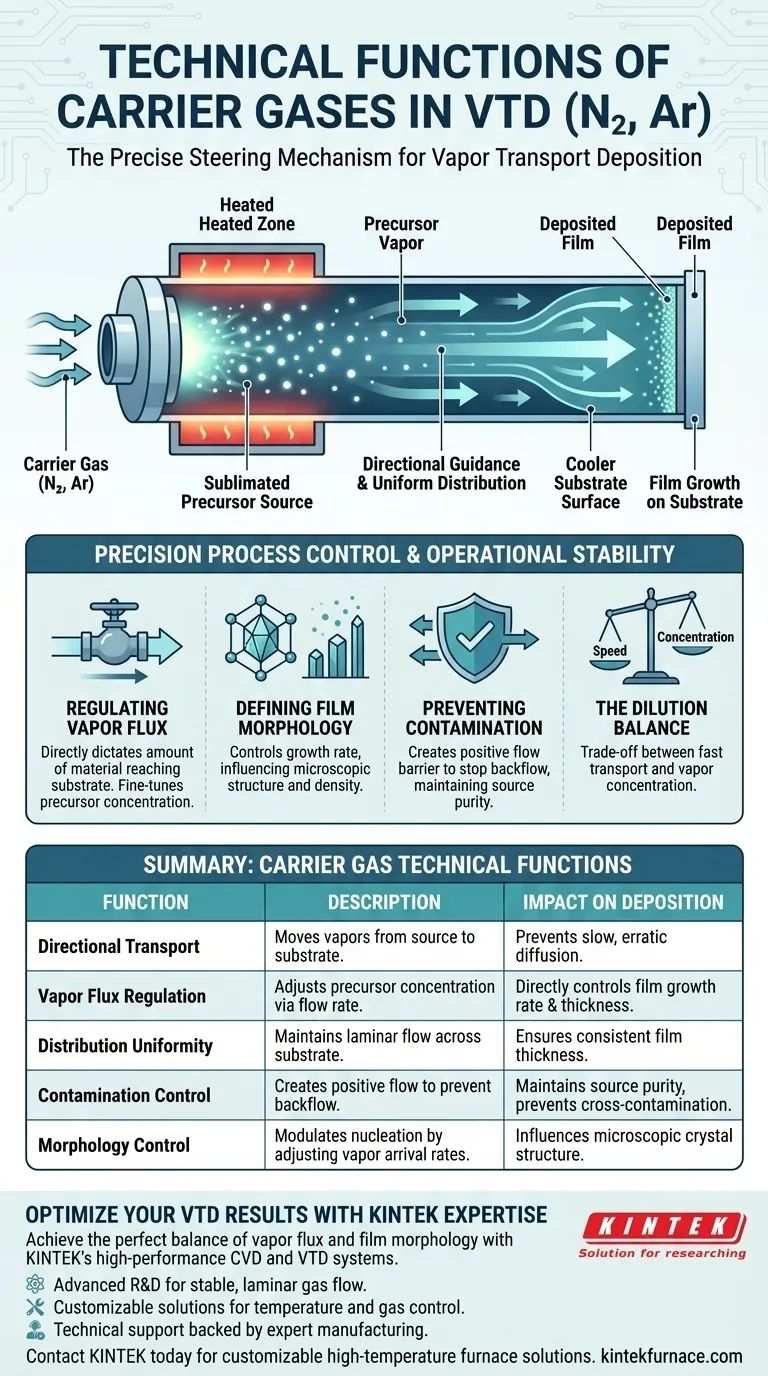

Carrier gases serve as the precise steering mechanism of the deposition process. In Vapor Transport Deposition (VTD), inert gases like nitrogen (N2) or argon (Ar) function primarily as both a transport medium and a diluent for sublimated precursor vapors. They are technically responsible for moving vapors efficiently from the source to the substrate while enabling the regulation of the deposition environment.

By manipulating the carrier gas, you directly control the density and velocity of the vapor reaching the substrate. This makes the gas flow the primary lever for determining the film's growth rate, structural morphology, and overall consistency.

The Mechanics of Vapor Transport

Directional Guidance

The fundamental role of the carrier gas is to provide directional transport. It physically carries sublimated precursor vapors from the source zone toward the cooler substrate surface. Without this driven flow, vapor movement would be reliant on diffusion, which is often too slow or erratic for controlled deposition.

Ensuring Uniform Distribution

Beyond simple movement, the gas aids in the uniform distribution of the vapor. By maintaining a laminar or controlled flow profile, the gas ensures that the precursor material spreads evenly across the substrate. This is critical for achieving consistent film thickness across the entire sample area.

Precision Process Control

Regulating Vapor Flux

The flow rate of the carrier gas directly dictates the vapor flux—the amount of material reaching the substrate per unit of time. By adjusting this flow, you can fine-tune the concentration of the precursor in the reaction chamber. This allows for dynamic control over how much material is available for deposition at any given moment.

Defining Film Morphology

Because the carrier gas controls the flux, it consequently regulates the film growth rate. The rate at which material arrives determines how the film nucleates and grows. Precise management of the gas flow allows engineers to influence the microscopic structure (morphology) of the final film.

Operational Stability and Trade-offs

Preventing Contamination

A critical, often overlooked function of the carrier gas is preventing precursor backflow. A continuous positive flow creates a barrier that stops downstream vapors or reaction byproducts from drifting back into the source region. This maintains the purity of the source material and prevents cross-contamination within the system.

The Dilution Balance

While higher flow rates improve transport speed, the carrier gas also acts as a diluent. There is a trade-off between transporting material quickly and diluting the vapor concentration too heavily. finding the correct balance is necessary to maintain an efficient deposition rate without starving the substrate of material.

Optimizing Your Deposition Strategy

To achieve high-quality films, you must view the carrier gas as a variable tool rather than a static setting.

- If your primary focus is film uniformity: Prioritize a stable, optimized flow rate that ensures the vapor is spread progressively and evenly across the substrate surface without turbulence.

- If your primary focus is morphology control: Use the gas flow rate to modulate the vapor flux, slowing it down or speeding it up to influence the crystal structure and growth density of the film.

Mastering the dynamics of your carrier gas is essential for strictly controlling the physical properties of your deposited material.

Summary Table:

| Technical Function | Description | Impact on Deposition |

|---|---|---|

| Directional Transport | Moves sublimated vapors from source to substrate. | Prevents reliance on slow/erratic diffusion. |

| Vapor Flux Regulation | Adjusts precursor concentration via flow rate. | Directly controls film growth rate and thickness. |

| Distribution Uniformity | Maintains laminar flow across the substrate. | Ensures consistent film thickness across the sample. |

| Contamination Control | Creates positive flow to prevent vapor backflow. | Maintains source purity and prevents cross-contamination. |

| Morphology Control | Modulates nucleation by adjusting vapor arrival rates. | Influences the microscopic crystal structure of the film. |

Optimize Your VTD Results with KINTEK Expertise

Achieving the perfect balance of vapor flux and film morphology requires precision-engineered equipment. KINTEK provides high-performance CVD and Vapor Transport Deposition systems specifically designed to handle complex gas dynamics.

Why partner with KINTEK?

- Advanced R&D: Systems engineered for stable, laminar gas flow to ensure superior film uniformity.

- Customizable Solutions: Our muffle, tube, and vacuum furnaces are tailored to your specific temperature and gas control needs.

- Technical Support: Backed by expert manufacturing to help you master precursor transport and deposition rates.

Ready to elevate your material research? Contact KINTEK today to discuss your laboratory's high-temperature furnace requirements and find the perfect customizable solution for your unique application.

Visual Guide

References

- Dachang Liu. Vapor Transport Deposition Technology for Perovskite Films. DOI: 10.1002/admi.202500064

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What functions does glucose perform in lithium-ion sieve synthesis? Enhance Carbothermal Reduction for LiMnO2 Purity

- What are the primary functions of a high-precision dilatometer in hot ductility? Optimize Steel Casting Precision

- Why are raw materials compacted into briquettes for vacuum carbothermal reduction? Optimize Your Magnesium Production

- What role does a vacuum oven play in determining the moisture content of mercury-depleted coal adsorbents? Key Insights

- What is the primary function of a constant temperature drying oven in ceramic powder pretreatment? Get Expert Results

- What role does quartz sand filler play in a crystal growth furnace? Enhance Thermal Symmetry and Yield

- Why must (MnFeNiCo)3O4 materials undergo a secondary calcination? Key Steps to Optimizing FCC Spinel Structure

- What are the equipment requirements for THM vs Bridgman? Achieve Ultra-Stable CZT Crystal Growth