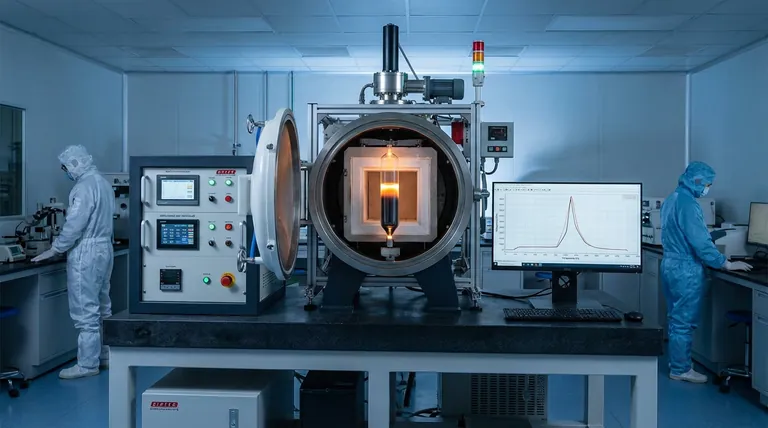

The primary equipment differentiator for the Traveling Heater Method (THM) is the requirement for an extremely stable, multi-zone temperature control system. Unlike the Bridgman method, which focuses on directional solidification of a melt, THM equipment must precisely maintain a central, tellurium-rich solvent zone while managing specific lower thermal gradients at the crystal interfaces.

The complexities of THM equipment are necessary to support continuous dissolution and precipitation. This precise thermal management enables the growth of large-volume Cadmium Zinc Telluride (CZT) single crystals with superior uniformity and lower defect densities compared to standard melt techniques.

The Critical Role of Multi-Zone Temperature Control

To understand the equipment requirements, one must look at the function the hardware must perform. THM is a solution growth technique, not a simple melt technique.

Maintaining the Solvent Zone

The core requirement of THM hardware is the ability to create and sustain a specific central melting zone.

According to the technical data, this zone is tellurium-rich. The equipment must keep this zone at a constant temperature to act as a stable solvent for the polycrystalline source material.

Precise Gradient Management

Beyond the central zone, the furnace must control the temperature profile at the boundaries.

The system is required to maintain lower temperature gradients at both ends of the heater. This contrasts with methods that may utilize steeper gradients to force crystallization.

Stability is Paramount

The reference emphasizes that the control system must be "extremely stable."

Fluctuations in temperature can disrupt the dissolution and precipitation process. High-precision controllers are essential to ensure the interface remains consistent throughout the growth cycle.

Contrasting with the Bridgman Method

While the Bridgman method generally utilizes a furnace with a temperature gradient to move a liquid-solid interface, THM equipment creates a distinct environment.

Continuous Dissolution and Precipitation

Bridgman equipment is designed to solidify a stoichiometric melt. THM equipment, however, is engineered to support a continuous cycle.

The hardware enables solutes to dissolve at the top interface of the solvent zone and precipitate at the bottom. This requires a moving heater (or moving ampoule) that allows the solvent zone to traverse the material.

Defect Density Control

The ultimate goal of the THM equipment configuration is quality over speed.

By maintaining a distinct solvent zone, the equipment facilitates the growth of crystals with higher uniformity. This setup specifically targets the reduction of defect density, a common challenge in Bridgman-grown CZT.

Understanding the Trade-offs

While THM offers superior crystal quality, the equipment requirements introduce specific challenges that must be weighed against the simpler Bridgman approach.

Increased Complexity

The need for multi-zone control significantly increases the complexity of the furnace design. Calibrating multiple zones to maintain a precise, moving solvent zone is more technically demanding than establishing a static gradient.

Sensitivity to Fluctuations

Because the process relies on dissolution and precipitation within a narrow zone, the equipment is less forgiving. Any instability in the power supply or thermal control can lead to inclusions or structural defects in the final crystal.

Making the Right Choice for Your Goal

The choice between THM and Bridgman equipment often comes down to the required specifications of the final CZT material.

- If your primary focus is crystal uniformity: THM equipment is essential, as the stable multi-zone control minimizes segregation and ensures consistent material properties.

- If your primary focus is minimizing defects: The THM process is superior, offering the precise thermal environment needed to achieve low defect density in large-volume single crystals.

Success in CZT preparation via THM relies entirely on the precision and stability of your thermal control architecture.

Summary Table:

| Feature | Traveling Heater Method (THM) | Bridgman Method |

|---|---|---|

| Core Mechanism | Continuous dissolution/precipitation | Directional solidification of melt |

| Temperature Control | Multi-zone, extremely stable solvent zone | Static or moving thermal gradient |

| Thermal Gradient | Lower gradients at interfaces | Typically steeper gradients |

| Crystal Quality | Superior uniformity, lower defect density | Higher risk of segregation/defects |

| Design Complexity | High (precise moving solvent zone) | Moderate (directional solidification) |

Optimize Your Crystal Growth with KINTEK Precision

High-performance CZT production demands unparalleled thermal stability. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, and Vacuum furnace systems engineered to maintain the precise multi-zone control required for THM processes.

Whether you need standard lab equipment or a customizable high-temp furnace tailored to your unique research needs, our team provides the hardware necessary to achieve superior material uniformity.

Ready to elevate your lab's capabilities? Contact us today to discuss your technical requirements.

References

- Z. J. Li, Zeqian Wu. Research on the Technological Progress of CZT Array Detectors. DOI: 10.3390/s24030725

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the significance of the two-step carbonization process for EN-LCNF? Unlock High-Performance Energy Storage

- Why is an aging station required for Ni-doped LaFeO3 gas sensors? Ensure Stability and Precision

- What is the function of a Mass Flow Controller (MFC)? Achieve Precise Ethanol Vapor Delivery for Graphene Synthesis

- Why is a vacuum drying oven required for precursor mixtures? Achieve Stable, High-Quality Powder Processing

- How does a batch furnace operate and what are its advantages? Boost Precision and Flexibility in Heat Treatment

- What are the advantages of using ultrasonic spray pyrolysis for metal powder? Achieve High Purity & Sphericity

- Why is carbon dioxide utilized for the in-situ gasification regeneration of NiCuCe catalysts? Enhance Catalyst Longevity

- What is the purpose of equipping the condensation section of a sodium heat pipe with a specialized insulation cover?