Ultrasonic spray pyrolysis is a precision manufacturing technique designed to overcome the limitations of traditional mechanical atomization. By utilizing ultrasonic waves to atomize precursor solutions into extremely fine droplets before reducing them in a furnace, this equipment provides a superior method for creating high-quality metal powders.

The core value of ultrasonic spray pyrolysis lies in its precision control. It transforms liquid solutions into ultra-fine, highly spherical, and pure metal powders with a uniformity that is essential for modern, high-performance material applications.

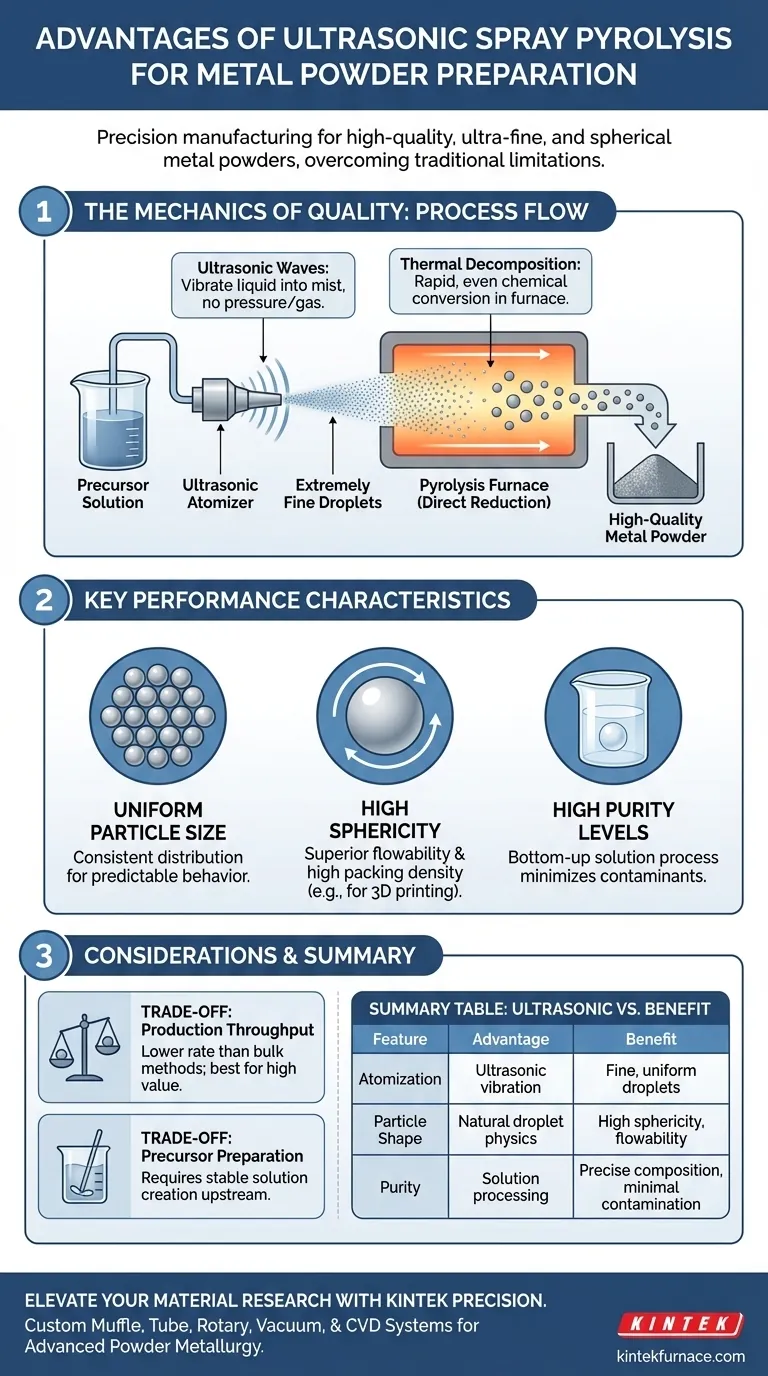

The Mechanics of Quality

The Role of Ultrasonic Atomization

The fundamental advantage of this equipment is the use of ultrasonic waves rather than pressure or gas to break down fluids.

This mechanism vibrates the liquid precursor solution at specific frequencies.

The result is the generation of a mist composed of extremely fine droplets, which serves as the foundation for the final powder's quality.

Direct Reduction

Once atomized, these droplets are introduced directly into a pyrolysis furnace.

Here, the droplets undergo thermal decomposition and reduction.

Because the starting material is a fine mist, the chemical conversion happens rapidly and evenly throughout the droplet volume.

Key Performance Characteristics

Uniform Particle Size Distribution

One of the most critical challenges in powder metallurgy is achieving consistency.

Ultrasonic equipment produces droplets of a nearly identical size.

Consequently, the resulting metal or alloy powders exhibit a uniform particle size distribution, ensuring predictable behavior in final applications.

High Sphericity

The physics of droplet formation naturally favors a spherical shape.

This geometry is retained as the droplet dries and reacts in the furnace.

High sphericity improves the flowability of the powder and allows for higher packing density, which is vital for processes like 3D printing and sintering.

High Purity Levels

The process begins with a solution rather than a bulk solid, allowing for high control over chemical composition.

This "bottom-up" approach minimizes the introduction of foreign contaminants.

The result is high purity ultra-fine powder, meeting the strict standards required for advanced alloy development.

Understanding the Trade-offs

Production Throughput

While this method excels in quality, it is generally a solution-based process.

This often means the production rate (volume per hour) may be lower compared to coarse, bulk industrial atomization methods.

It is best reserved for high-value applications where quality trumps raw tonnage.

Precursor Preparation

The process relies on the ability to create a stable precursor solution.

Users must ensure their target metal or alloy can be dissolved effectively.

This adds a chemical preparation step upstream that is not present in melt-based atomization.

Aligning Technology with Production Goals

To determine if ultrasonic spray pyrolysis is the right solution for your facility, consider your specific material requirements.

- If your primary focus is High-Performance Materials: This equipment is ideal, as it delivers the purity and uniformity required for critical applications like aerospace or medical devices.

- If your primary focus is Powder Flowability: The high sphericity offered by this process provides excellent flow characteristics for additive manufacturing.

- If your primary focus is Alloy Complexity: The solution-based approach allows for precise mixing of elements at the molecular level before powder formation.

By prioritizing particle control over bulk volume, ultrasonic spray pyrolysis enables the creation of next-generation materials that standard methods simply cannot match.

Summary Table:

| Feature | Advantage of Ultrasonic Spray Pyrolysis | Benefit to Metal Powder |

|---|---|---|

| Atomization Method | Ultrasonic wave vibration (no pressure/gas) | Extremely fine, uniform droplet formation |

| Particle Shape | Natural droplet physics | High sphericity for superior flowability |

| Purity Level | Bottom-up solution processing | Minimal contamination and precise composition |

| Size Distribution | Consistent droplet frequency | Uniform particles for predictable sintering |

| Alloy Control | Molecular-level solution mixing | High precision for complex material development |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of advanced powder metallurgy with KINTEK’s high-performance laboratory solutions. Backed by expert R&D and world-class manufacturing, we offer specialized Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique ultrasonic spray pyrolysis and thermal processing needs.

Whether you are developing next-generation alloys for aerospace or optimizing powders for 3D printing, our team provides the technical expertise and equipment precision you require. Contact KINTEK today to discuss your custom furnace solution and see how we can bring unparalleled uniformity and purity to your production process.

Visual Guide

References

- Srečko Stopić. Feature Papers in Extractive Metallurgy. DOI: 10.3390/met15070751

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Spark Plasma Sintering SPS Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- What role does a vacuum drying oven play in the post-processing of Fe3O4 magnetic nanoparticles? Ensure Phase Purity

- What is the function of a Mass Flow Controller (MFC)? Achieve Precise Ethanol Vapor Delivery for Graphene Synthesis

- What role do RTP or continuous sintering furnaces play in solar cell electrode formation? Optimize Your Firing Process

- What is the effect of sintering BZCYYb electrolyte pellets at 1000°C? Boost Your PCFC Performance Today

- Process conditions for HEA cladding thermal experiments: Ensuring 800°C stability and 1680-hour endurance.

- How do continuous furnaces differ from batch furnaces? Choose the Right Furnace for Your Production Needs

- What is the significance of a laboratory vacuum drying oven in the treatment of hybrid membranes? | Optimize Performance

- How do quartz-capped vials facilitate the pyrolysis of magnetic chitosan carbon? Master Localized Reducing Atmospheres