The primary function of a specialized insulation cover or heat shield on a sodium heat pipe’s condensation section is to regulate the rate of heat dissipation during the startup process. By significantly reducing the heat exchange coefficient between the pipe and the surrounding environment, the shield prevents excessive heat loss. This ensures the internal temperature remains high enough to fully melt the sodium working medium, allowing the system to overcome the "frozen startup" limit and reach full thermal activation.

Core Takeaway: High-aspect-ratio sodium heat pipes often fail to start because heat escapes the condensation end faster than it can melt the working fluid. An insulation cover acts as a thermal damper, retaining sufficient energy to ensure a smooth transition from a frozen state to stable operation.

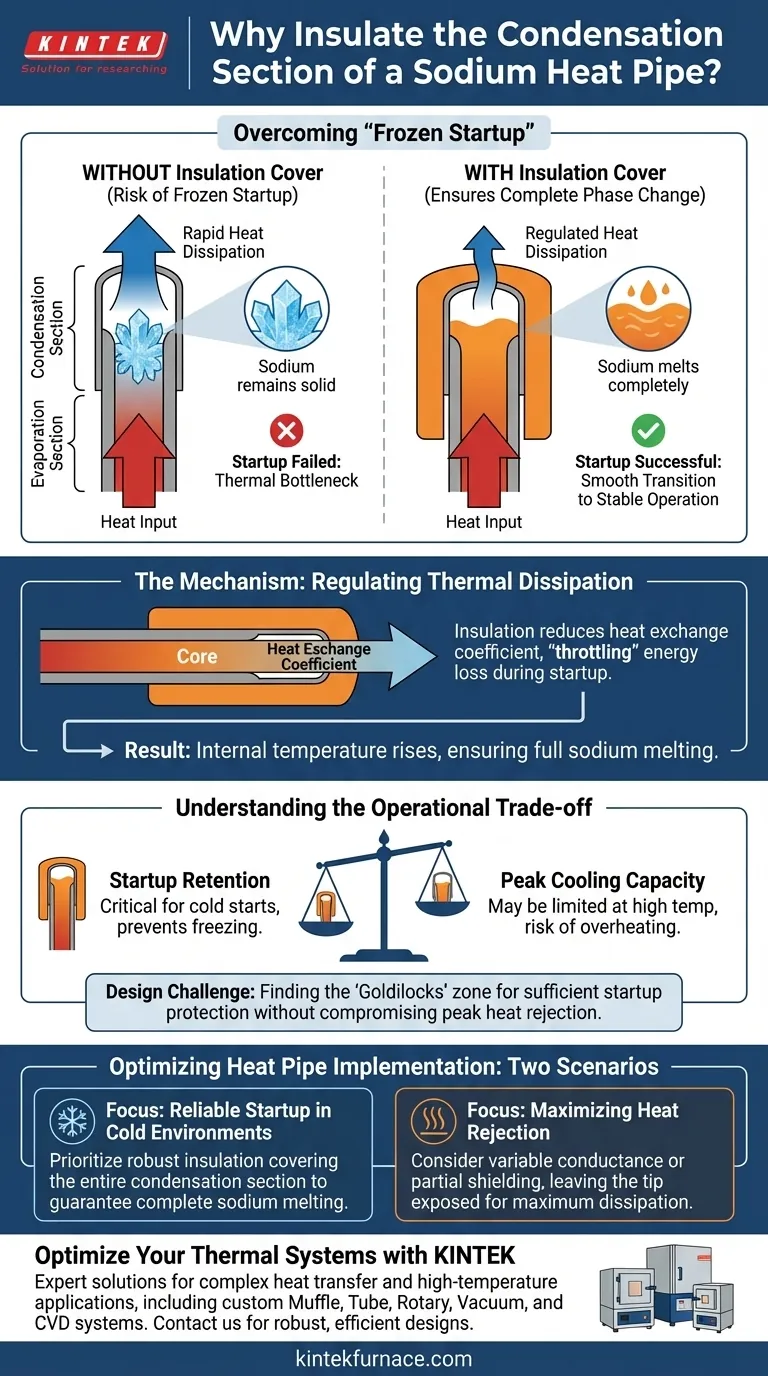

Overcoming the Frozen Startup Challenge

The Risk of Excessive Heat Dissipation

For sodium heat pipes, particularly those with a high aspect ratio (long and thin), the condensation section represents a large surface area for potential heat loss.

If this section is directly exposed to the environment during startup, heat flows out too rapidly. This creates a thermal bottleneck where the energy input at the evaporation end is insufficient to maintain the temperature required at the condensation end.

Ensuring Complete Phase Change

The working medium (sodium) must be in a liquid or vapor state to circulate and transfer heat effectively.

Without shielding, the rapid heat loss can keep the condensation section temperature too low. This prevents the sodium from melting completely or causes it to re-solidify before it can return to the evaporation section, leading to startup failure or stalling.

The Mechanism of Thermal Regulation

Modifying the Heat Exchange Coefficient

The insulation cover works by altering the thermal boundary of the heat pipe.

Technically, it reduces the heat exchange coefficient between the condensation section and the external environment. This effectively "throttles" the rate at which energy leaves the system.

Facilitating Smooth Activation

The ultimate goal of this regulation is to secure a smooth transition curve.

By retaining heat during the critical initial moments, the shield allows the internal pressure and temperature to build gradually. This enables the heat pipe to transition safely through the frozen startup phase until it reaches a self-sustaining operating temperature.

Understanding the Operational Trade-offs

Impact on Steady-State Cooling

While insulation is vital for startup, it inherently limits the heat pipe's ability to shed heat once it is fully active.

If the insulation is too heavy, it may restrict the condensation section's capacity to reject heat during peak operation, potentially leading to overheating of the source.

Balancing Startup vs. Performance

The design challenge lies in finding the "Goldilocks" zone.

The shielding must be substantial enough to prevent freezing during startup, but permeable or limited enough to allow necessary heat transfer once the system reaches its nominal high-temperature operating range.

Optimizing Heat Pipe Implementation

To apply this to your specific thermal management project, consider your system's constraints:

- If your primary focus is reliable startup in cold environments: Prioritize a robust insulation cover that encompasses the entire length of the condensation section to guarantee the sodium melts completely.

- If your primary focus is maximizing heat rejection capacity: Investigate variable conductance solutions or partial shielding that protects the tip of the condenser while leaving the rest exposed for maximum dissipation.

By carefully managing the thermal boundary at the condensation section, you transform a potentially unstable component into a robust, self-starting thermal management system.

Summary Table:

| Feature | Impact on Sodium Heat Pipe Performance |

|---|---|

| Primary Function | Regulates heat dissipation rate during the critical startup phase |

| Thermal Mechanism | Reduces the heat exchange coefficient at the condensation section |

| Startup Benefit | Overcomes "frozen startup" limits by ensuring sodium fully melts |

| Internal Effect | Maintains high enough internal temperature/pressure for circulation |

| Design Trade-off | Must balance startup thermal retention with peak heat rejection needs |

Optimize Your Thermal Systems with KINTEK

Struggling with complex heat transfer challenges or frozen startup failures? At KINTEK, we understand the precision required for high-temperature applications. Backed by expert R&D and manufacturing, we offer advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to your unique thermal management needs.

Let our experts help you design a robust, efficient system today.

Contact KINTEK for Custom Solutions

Visual Guide

References

- Shuaijie Sha, Junjie Wang. Experimental and numerical simulation study of sodium heat pipe with large aspect ratio. DOI: 10.2298/tsci231030059s

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a vacuum drying oven provide superior performance for MoS2/C powders? Preserve Purity and Nanostructure

- How does Vacuum Degassing (VD) influence spinel inclusions in heavy rail steel? Controlling Refractory Erosion

- Why is precise temperature control necessary for drying plum stone raw materials? Enhance Biochar Quality & Grinding

- What thermochemical environment does an entrained flow reactor provide? Simulate Industrial Biomass Combustion

- What is the primary function of the low-temperature pyrolysis process? Ensure Safe Battery Recycling with Pretreatment

- What is the effect of sintering BZCYYb electrolyte pellets at 1000°C? Boost Your PCFC Performance Today

- Why is a high-pressure digestion tank essential for ZnO/rGO hydrothermal synthesis? Achieve superior interfacial coupling

- What is the purpose of adding metal oxides such as copper oxide (CuO) in RAB? Enhancing Air Brazing & Ceramic Bonding