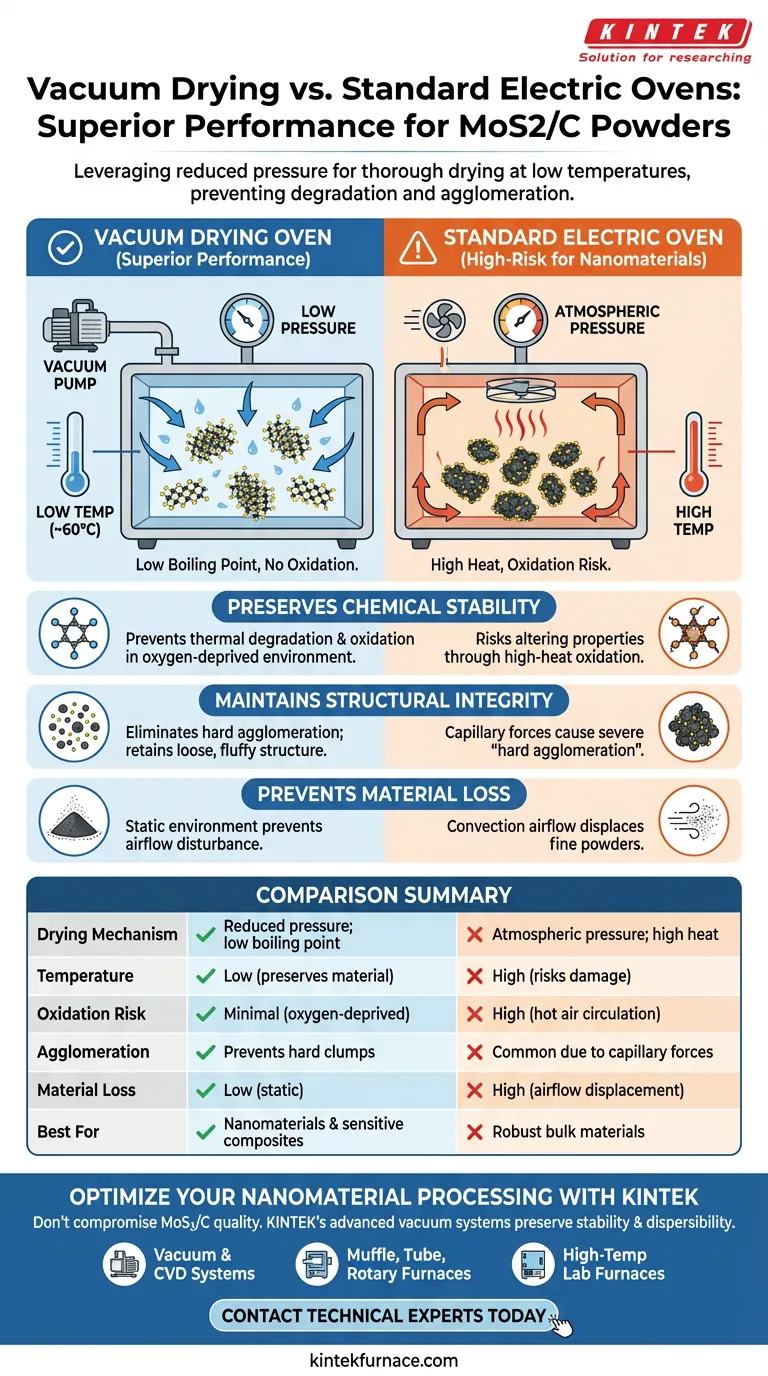

Vacuum drying ovens provide superior performance by leveraging reduced pressure to lower the boiling point of solvents. This allows MoS2/C powders to dry thoroughly at significantly lower temperatures, which prevents the oxidation and thermal degradation often caused by the high heat of standard electric ovens. Furthermore, the vacuum environment exerts negative pressure that actively extracts trace liquids from particle pores, preventing the severe hard agglomeration that compromises the material's dispersibility.

By decoupling drying efficiency from high temperatures, vacuum ovens preserve the chemical stability and nanostructure of MoS2/C powders, whereas standard thermal drying risks altering the material's fundamental properties through oxidation and capillary stress.

The Mechanics of Low-Temperature Preservation

Lowering the Boiling Point

Standard electric ovens rely on atmospheric pressure, requiring high temperatures to evaporate solvents.

A vacuum oven reduces the internal pressure of the chamber. This drop in pressure significantly lowers the boiling point of water and other solvents, allowing volatilization to occur at much lower temperatures (e.g., 60 °C).

Preventing Thermal Degradation

MoS2/C is a composite material that can degrade or change chemically when exposed to excessive heat.

By operating at lower temperatures, vacuum drying prevents thermal stress that could damage the carbon matrix or alter the crystalline structure of the Molybdenum Disulfide (MoS2).

Eliminating Oxidation Risks

Standard ovens typically circulate hot air, which exposes the powder to oxygen during the heating process.

Vacuum drying removes air from the chamber. This oxygen-deprived environment is critical for preventing the oxidation of the MoS2/C surface, ensuring the chemical composition remains stable.

Preserving Structural Integrity

Overcoming Capillary Forces

In a standard drying process, as liquid evaporates from pores, surface tension creates strong capillary forces.

These forces pull nanoparticles together, resulting in "hard agglomeration"—dense clumps that are difficult to break apart later.

Extracting Liquid from Pores

The negative pressure in a vacuum oven facilitates the rapid removal of trace liquids deep within the particle pores.

By removing this liquid quickly and efficiently, the vacuum process minimizes the duration and intensity of capillary forces.

Maintaining High Dispersibility

Because hard agglomerates are prevented, the final MoS2/C powder retains a loose, fluffy structure.

This ensures high dispersibility, which is essential for the material's performance in applications like catalysis or battery electrodes, where surface area is paramount.

Common Pitfalls and Trade-offs

The Risk of Airflow Disturbance

Standard electric ovens often use convection fans to distribute heat.

For ultra-fine powders like MoS2/C, this airflow can physically blow the powder away, leading to material loss. Vacuum ovens operate statically, eliminating this risk.

Speed vs. Complexity

Standard ovens are generally simpler to operate and allow for continuous airflow.

Vacuum ovens require sealing and pump operation, making them a batch process that requires more setup but delivers the critical quality needed for nanomaterials.

Making the Right Choice for Your Goal

While standard ovens are sufficient for bulk drying of robust materials, MoS2/C requires precision.

- If your primary focus is preserving active surface area: Choose the vacuum oven to prevent pore collapse and hard agglomeration caused by capillary forces.

- If your primary focus is chemical purity: Choose the vacuum oven to eliminate the risk of oxidation and thermal degradation inherent in high-temperature air drying.

- If your primary focus is preventing material loss: Choose the vacuum oven to avoid the airflow disturbances of convection heating that displace fine powders.

For high-performance nanomaterials like MoS2/C, vacuum drying is not just an alternative; it is a technical necessity for retaining material integrity.

Summary Table:

| Feature | Vacuum Drying Oven | Standard Electric Oven |

|---|---|---|

| Drying Mechanism | Reduced pressure; lower boiling point | Atmospheric pressure; high heat |

| Temperature | Low (prevents thermal degradation) | High (risks oxidation/damage) |

| Oxidation Risk | Minimal (oxygen-deprived environment) | High (continuous hot air circulation) |

| Agglomeration | Prevents hard clumps; maintains porosity | Common due to high capillary forces |

| Material Loss | Low (static drying environment) | High (airflow can displace fine powders) |

| Best For | Nanomaterials & sensitive composites | Robust bulk materials |

Optimize Your Nanomaterial Processing with KINTEK

Don't let oxidation or agglomeration compromise the quality of your MoS2/C powders. KINTEK’s advanced vacuum systems are designed to preserve the chemical stability and dispersibility of your most sensitive materials. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of customizable solutions including:

- Vacuum & CVD Systems for precise atmosphere control.

- Muffle, Tube, and Rotary Furnaces for diverse lab requirements.

- High-Temp Lab Furnaces tailored to your unique research needs.

Ready to elevate your material performance? Contact our technical experts today to find the perfect drying solution for your laboratory.

Visual Guide

References

- One-Pot Hydrothermal Synthesis and Electrochemical Performance of Subspheroidal Core–Shell Structure MoS2/C Composite as Anode Material for Lithium-Ion Batteries. DOI: 10.3390/en17071678

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What are the advantages and disadvantages of microwave drying for iron ore briquettes? Expert Process Insights

- How does the electric arc furnace contribute to carbon neutrality? Decarbonizing Steel with EAF Technology

- What is the purpose of treating EAF dust in a dryer? Ensure Precise Material Characterization & Data Integrity

- What are the advantages of Spark Plasma Sintering (SPS)? Enhance Thermoelectric Performance in Copper Sulfide

- What role does a PID controller play in the calcination process of eggshells? Precision Control for Pure Calcium Oxide

- How does a temperature-controlled experimental platform support the testing of Mn3O4 memristor stability?

- What is the function of ZrCp(NMe2)3? Master Precision Surface Passivation in Area-Selective ALD

- Why is the calcination step essential for Copper Ferrite? Unlock High Purity & Superior Crystallinity