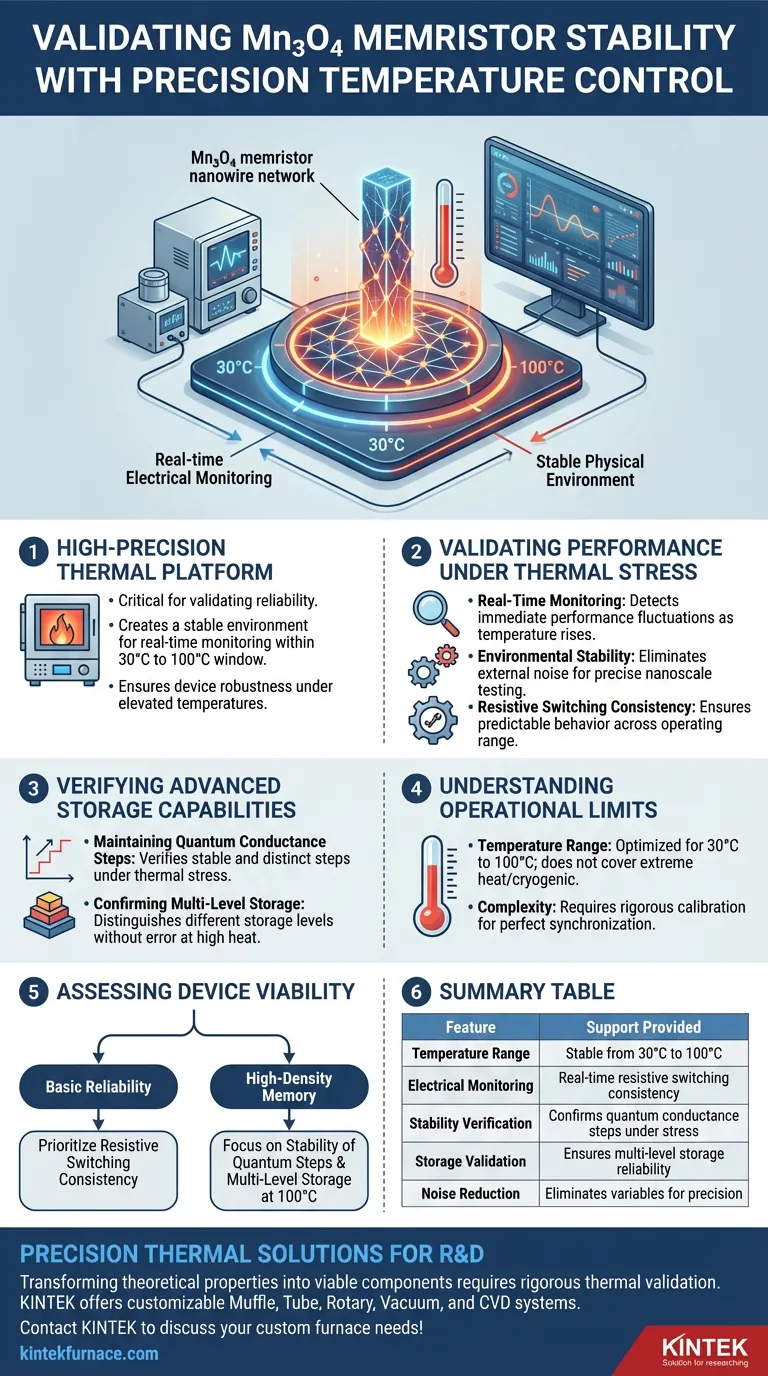

A high-precision temperature-controlled platform serves as the critical foundation for validating the reliability of Mn3O4 memristors. It creates a stable physical environment that allows for real-time electrical monitoring within a specific thermal window of 30 °C to 100 °C.

The core function of this platform is to prove device robustness; it verifies that Mn3O4 nanowire networks can maintain stable quantum conductance steps and multi-level storage capabilities even when subjected to elevated temperatures.

Validating Performance Under Thermal Stress

Real-Time Electrical Monitoring

The platform's primary role is to enable continuous observation of the device's electrical behavior.

By monitoring the device in real-time, researchers can detect immediate fluctuations in performance as the temperature rises.

Establishing Environmental Stability

Testing nanoscale devices requires the elimination of external variables.

This platform provides a stable physical environment, ensuring that any observed changes in the Mn3O4 nanowire networks are due to thermal conditions rather than environmental noise.

Analyzing Resistive Switching Consistency

The utility of a memristor depends on its ability to switch states reliably.

The platform tests the consistency of resistive switching in Mn3O4 networks. This ensures the device behaves predictably across the entire 30 °C to 100 °C operating range.

Verifying Advanced Storage Capabilities

Maintaining Quantum Conductance Steps

Mn3O4 memristors utilize quantum conductance steps for their operation.

The temperature-controlled platform verifies that these delicate quantum steps remain stable and distinct at higher temperatures. This confirms the fundamental physics of the device hold up under stress.

Confirming Multi-Level Storage

For high-density memory applications, a device must support multi-level storage.

The testing setup confirms that the memristor can distinguish between different storage levels without error, even when the thermal environment changes.

Understanding the Operational Limits

The Temperature Range Constraint

The platform is optimized for a specific range of 30 °C to 100 °C.

While this covers standard electronic operating temperatures, it does not validate performance for extreme industrial heat or cryogenic applications.

Complexity of Real-Time Analysis

Achieving high precision in temperature control often adds complexity to the experimental setup.

Ensuring that real-time electrical data is perfectly synchronized with temperature changes requires rigorous calibration of the platform.

Assessing Device Viability for Your Application

To determine if this testing approach aligns with your development goals, consider the following:

- If your primary focus is basic device reliability: Prioritize the data regarding resistive switching consistency to ensure the device does not fail under standard heating.

- If your primary focus is high-density memory development: Focus heavily on the stability of quantum conductance steps and multi-level storage metrics at the upper limit (100 °C).

Thermal validation is the critical step that transforms a theoretical material property into a viable, real-world electronic component.

Summary Table:

| Feature | Support Provided for Mn3O4 Memristors |

|---|---|

| Temperature Range | Stable testing environment from 30°C to 100°C |

| Electrical Monitoring | Real-time observation of resistive switching consistency |

| Stability Verification | Confirms quantum conductance steps under thermal stress |

| Storage Validation | Ensures multi-level storage reliability at high heat |

| Noise Reduction | Eliminates external environmental variables for nanoscale precision |

Precision Thermal Solutions for Your Advanced Electronics R&D

Transitioning theoretical material properties into viable, real-world components requires rigorous thermal validation. At KINTEK, we understand the precision required for testing nanoscale devices like Mn3O4 memristors.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique experimental constraints. Whether you are validating resistive switching consistency or high-density memory storage, our equipment provides the stable physical environment your research demands.

Ready to elevate your lab's testing capabilities? Contact KINTEK today to discuss your custom high-temperature furnace needs!

Visual Guide

References

- Keval Hadiyal, R. Thamankar. Quantized Conductance and Multilevel Memory Operation in Mn<sub>3</sub>O<sub>4</sub> Nanowire Network Devices Combined with Low Voltage Operation and Oxygen Vacancy Induced Resistive Switching. DOI: 10.1002/aelm.202500159

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the primary objective of processing high-purity quartz? Achieve 99.998% Purity for Tech Applications

- What is the role of a high-temperature reaction furnace in flame fusion? Master Alumina Spheroidization

- What is the purpose of mixing aluminum and iron powders at a specific atomic ratio? Optimize Al-Fe Alloy Phases

- How does the introduction of SiO2 as an additive improve the sintering process of solid electrolytes? Boost Densification

- What is the role of industrial thermometers in monitoring thermal stress? Ensure Safety via High-Precision Data

- What is the benefit of accessing furnace technical guides? Optimize Your Research with Precise Equipment Data

- What is the purpose of using an industrial oven for low-temperature drying? Expert Glass Processing Guide

- Why is instantaneous heating required for N-GC-X catalyst synthesis? Achieve Superior 2D Nanosheet Morphology