At its core, a batch furnace operates by heating and cooling a stationary load of material within a single, sealed chamber. This method is defined by its sequential, all-in-one process: parts are loaded, the furnace chamber is brought to a specific temperature for a set time, and then it is cooled in a controlled manner before the parts are removed. Its primary advantages are exceptional flexibility in handling diverse jobs and precise control over the entire thermal cycle.

A batch furnace is not designed for speed or mass production, but for control. It excels in applications where process flexibility and treatment uniformity are more critical than raw throughput, making it a cornerstone for custom or high-value manufacturing.

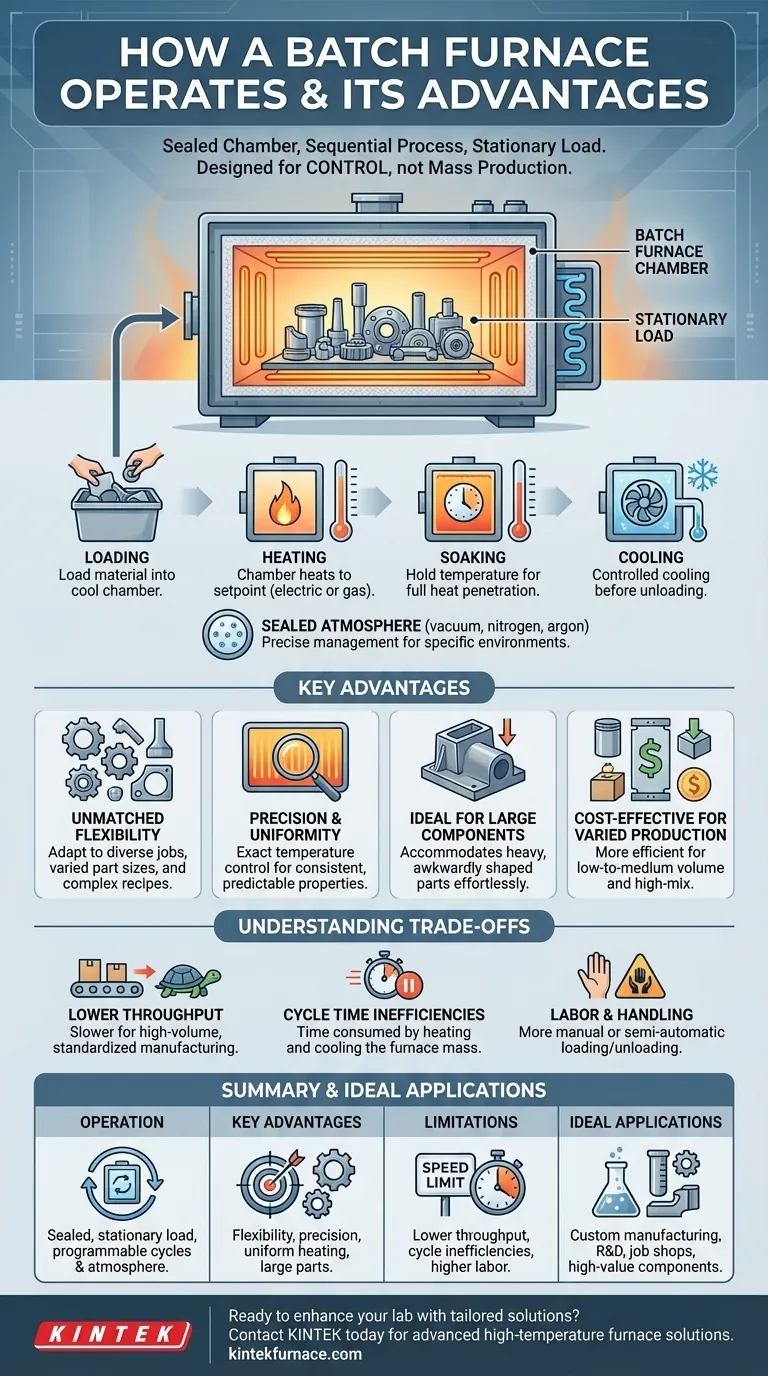

How a Batch Furnace Operates: The Core Principles

The operation of a batch furnace is simple in concept but allows for sophisticated process control. The entire heat treatment cycle is completed on a single "batch" of material before the next one begins.

The Stationary Batch Concept

Unlike a continuous furnace where parts move through different temperature zones, a batch furnace keeps the material stationary. The entire chamber environment—temperature and atmosphere—is changed around the static load.

This design is inherently versatile. A single furnace can be used for a wide variety of part sizes, weights, and material grades without mechanical reconfiguration.

Controlled Thermal Cycling

The process follows a distinct, programmable sequence:

- Loading: The material is placed inside the cool furnace chamber.

- Heating: Heating elements (electric or gas-fired) raise the chamber temperature to a predetermined setpoint.

- Soaking: The furnace holds this temperature for a specified duration to ensure the heat fully penetrates the entire batch.

- Cooling: The heat is turned off, and the batch cools down, either slowly inside the insulated furnace or through a more rapid, controlled process like forced air or liquid quenching.

Precise Atmosphere Management

Because the chamber is sealed for the duration of the cycle, the internal atmosphere can be tightly controlled. This is critical for processes that require a specific environment, such as a vacuum, an inert gas like nitrogen or argon, or an active gas to prevent oxidation or achieve a specific surface treatment.

The Key Advantages of Batch Processing

The batch method delivers several distinct benefits that make it the ideal choice for many applications.

Unmatched Flexibility

This is the hallmark advantage. A batch furnace can process a small run of large-castings one day and a different batch of small, complex components with a completely different heat treatment recipe the next. This adaptability is invaluable for job shops and R&D.

Precision and Uniformity

The static nature of the process allows for extremely precise control over heating and cooling rates. This ensures that every part within the batch, regardless of its position, experiences a highly uniform thermal cycle, leading to consistent and predictable material properties.

Ideal for Large or Heavy Components

Batch furnaces are exceptionally well-suited for processing very large, heavy, or awkwardly shaped parts that would be difficult or impossible to move through a continuous furnace system. The entire chamber is designed to accommodate the load.

Cost-Effectiveness for Varied Production

For low-to-medium volume production or when dealing with a high mix of different products, a batch furnace is more cost-effective. It avoids the significant capital investment and energy costs associated with keeping a large continuous furnace at a constant operating temperature.

Understanding the Trade-offs and Limitations

No single technology is a universal solution. Understanding the trade-offs of a batch furnace is critical for making an informed decision.

Lower Throughput

The most significant trade-off is production speed. The start-stop, one-batch-at-a-time nature of the process makes it inherently slower and less efficient for high-volume, standardized manufacturing compared to a continuous furnace.

Cycle Time Inefficiencies

The total cycle time includes heating the furnace from a low temperature, soaking, and then cooling it down. This heating and cooling of the furnace's own thermal mass for every batch can be time-consuming and less energy-efficient than a continuous system that remains hot.

Labor and Handling

Each batch must be manually or semi-automatically loaded and unloaded. This can require more operator intervention compared to the highly automated material handling systems often used with continuous furnaces.

How to Choose the Right Furnace for Your Process

The choice between a batch furnace and other types depends entirely on your production goals, material, and required process.

- If your primary focus is flexibility and process control: The batch furnace is the superior choice for handling diverse parts, complex heat treatment cycles, and high-value components.

- If your primary focus is high-volume, standardized production: A continuous furnace will deliver far greater throughput and energy efficiency for a single, repeatable process.

- If your primary focus is rapid heating or melting of metals: An induction furnace, which heats the material directly via an electromagnetic field, offers unmatched speed and is often cleaner.

- If your primary focus is small-scale lab work or sample testing: A tube furnace provides a highly controlled environment for processing small, contained samples and is not designed for production parts.

Ultimately, selecting the correct thermal processing technology is about aligning the equipment's capabilities with your specific manufacturing or research objectives.

Summary Table:

| Aspect | Details |

|---|---|

| Operation | Heats and cools a stationary load in a sealed chamber with programmable thermal cycles and atmosphere control. |

| Key Advantages | Unmatched flexibility for varied jobs, precise temperature control, uniform heating, ideal for large components, cost-effective for low-to-medium volumes. |

| Limitations | Lower throughput, cycle time inefficiencies, higher labor requirements compared to continuous furnaces. |

| Ideal Applications | Custom manufacturing, R&D, job shops, and high-value components requiring strict process control. |

Ready to enhance your lab's capabilities with tailored heat treatment solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need flexibility for diverse jobs or precision for high-value processes, we can help you achieve superior results.

Contact us today to discuss how our batch furnaces and other solutions can optimize your operations and drive innovation!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What technological features enhance the efficiency of vacuum furnaces? Boost Performance with Advanced Control & Energy Savings

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing