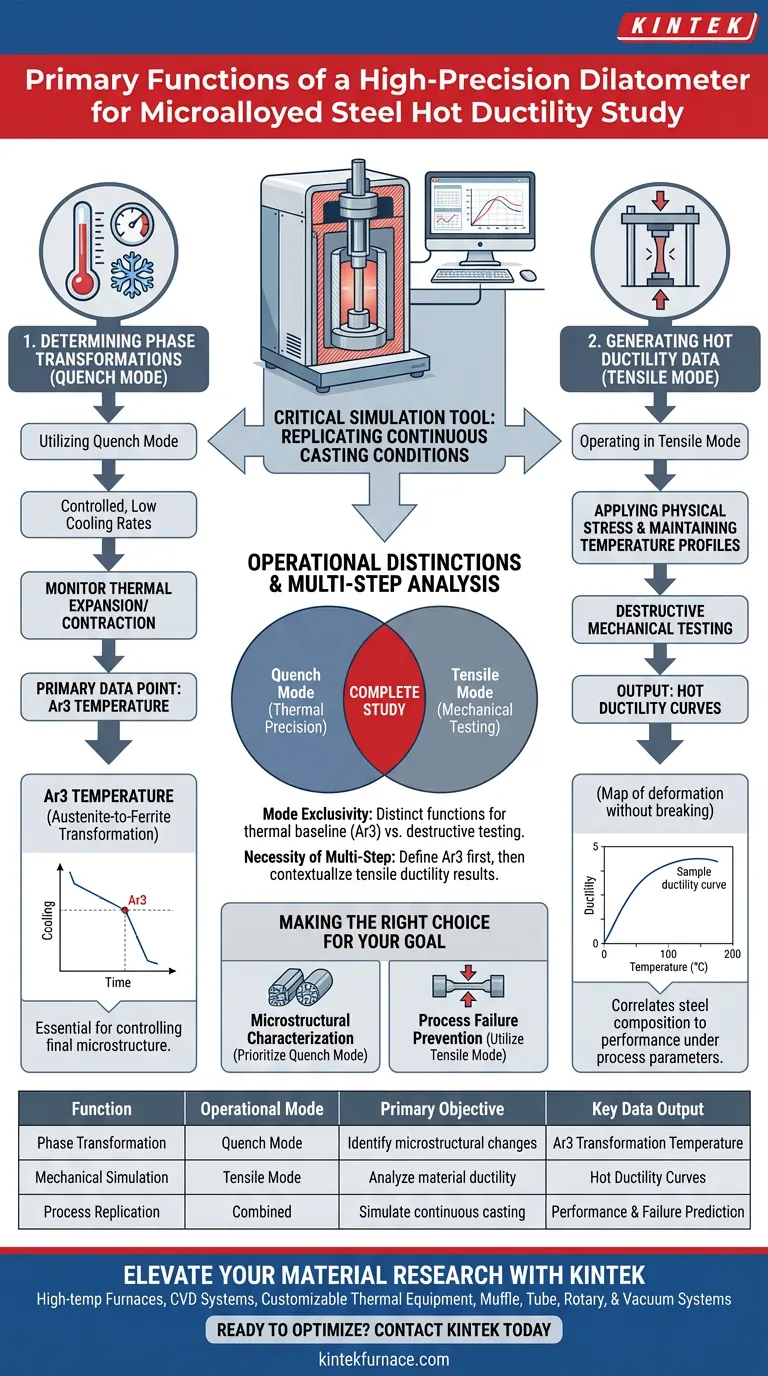

A high-precision dilatometer serves as a critical simulation tool for replicating the intense conditions of continuous casting in a controlled laboratory setting. Its primary functions are to pinpoint the austenite-to-ferrite transformation temperature (Ar3) via specific quench modes and to generate hot ductility curves through rigorous tensile testing sequences.

By simulating exact thermo-mechanical cycles, the dilatometer allows engineers to predict how microalloyed steel behaves during processing. It provides the essential data needed to optimize cooling strategies and prevent structural defects like cracking.

Simulating the Continuous Casting Process

Replicating Industrial Conditions

The core value of the dilatometer lies in its ability to mimic the specific thermo-mechanical cycles found in actual steel plants. It does not merely heat metal; it executes complex sequences of heating, cooling, and deformation.

The Importance of Microalloyed Steel Study

Microalloyed steels are highly sensitive to thermal variations. Precise simulation helps researchers understand exactly how these materials react to the thermal and physical stresses inherent in continuous casting.

Determining Critical Phase Transformations

Utilizing Quench Mode

To analyze phase changes without the interference of mechanical deformation, the instrument operates in a specific quench mode. This mode applies controlled, often low, cooling rates to the sample to monitor thermal expansion and contraction.

Identifying the Ar3 Temperature

The primary data point gathered during this process is the Ar3 temperature. This represents the critical threshold where austenite transforms into ferrite, a vital parameter for controlling the final microstructure of the steel.

Generating Hot Ductility Data

Operating in Tensile Mode

Beyond thermal analysis, the dilatometer functions as a mechanical tester using its tensile mode. This applies physical stress to the sample while strictly maintaining the temperature profiles associated with industrial processing.

Creating Hot Ductility Curves

The output of this mode is a hot ductility curve. These curves map the material's ability to deform without breaking, providing a direct correlation between the steel's composition and its performance under process parameters.

Operational Distinctions and Requirements

Mode Exclusivity

It is important to understand that while the device is versatile, its two primary functions operate in distinct modes. Quench mode is designed for thermal precision to find the Ar3 baseline, while tensile mode focuses on destructive mechanical testing.

The Necessity of Multi-Step Analysis

A complete study of hot ductility typically requires data from both functions. Researchers must define the transformation temperatures (Ar3) first to accurately contextualize the mechanical results obtained from the tensile ductility tests.

Making the Right Choice for Your Goal

To effectively study hot ductility in microalloyed steel, you must apply the specific machine mode that aligns with your immediate data requirements.

- If your primary focus is microstructural characterization: Prioritize the quench mode to accurately identify the Ar3 transformation temperature using low cooling rates.

- If your primary focus is process failure prevention: Utilize the tensile mode to generate ductility curves that reveal how the steel withstands deformation under specific process parameters.

By leveraging both operational modes, you transform raw material data into actionable process controls that ensure the integrity of the final steel product.

Summary Table:

| Function | Operational Mode | Primary Objective | Key Data Output |

|---|---|---|---|

| Phase Transformation | Quench Mode | Identify microstructural changes | Ar3 Transformation Temperature |

| Mechanical Simulation | Tensile Mode | Analyze material ductility | Hot Ductility Curves |

| Process Replication | Combined | Simulate continuous casting | Performance & Failure Prediction |

Elevate Your Material Research with KINTEK

Precision is the foundation of high-performance microalloyed steel. KINTEK provides industry-leading lab solutions, including high-temp furnaces, CVD systems, and customizable thermal equipment tailored for researchers and steel manufacturers.

Backed by expert R&D and manufacturing, we offer specialized Muffle, Tube, Rotary, and Vacuum systems designed to meet your most rigorous testing requirements. Whether you are optimizing cooling strategies or preventing structural cracks, our team is ready to deliver the high-precision tools your lab needs to succeed.

Ready to optimize your thermo-mechanical cycles? Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

References

- Serkan Turan, Heinz Palkowski. Microscopic Investigation for Experimental Study on Transverse Cracking of Ti-Nb Containing Micro-Alloyed Steels. DOI: 10.3390/ma17040900

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- Why do high-performance Bi-2223 superconducting materials require high-precision temperature control? | KINTEK Solution

- What are the advantages of directly adding heat carriers to oil sludge? Boost Efficiency & Preserve Resource Value

- What is the function of a laboratory drying oven in thin film solvent removal? Ensure Defect-Free Solidification

- Why is a precision electric heating reactor used for ozone treatment of porous graphene? Unlock Angstrom-Scale Accuracy

- Why is a constant temperature and humidity curing chamber essential for geopolymerization? Ensure Structural Strength

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- Why is a drying oven preferred for the post-treatment cleaning of activated carbon? Protect Your Material's Structure

- What are the functions of a programmed temperature rise experimental system? Master Coal Pre-Oxidation Research