At its core, the main purpose of heat treatment is to deliberately change a metal's internal structure to achieve a specific set of mechanical properties. By precisely controlling heating and cooling cycles, a metal can be made harder, stronger, and more resistant to impact, or conversely, it can be made softer and more ductile. This makes the material more useful, serviceable, and safe for its intended application.

Heat treatment is not a single action but a powerful metallurgical toolset. Its true purpose is to transform a standard metal into a high-performance material precisely engineered for a specific task, whether that requires extreme hardness for a cutting tool or ductility for a stamped part.

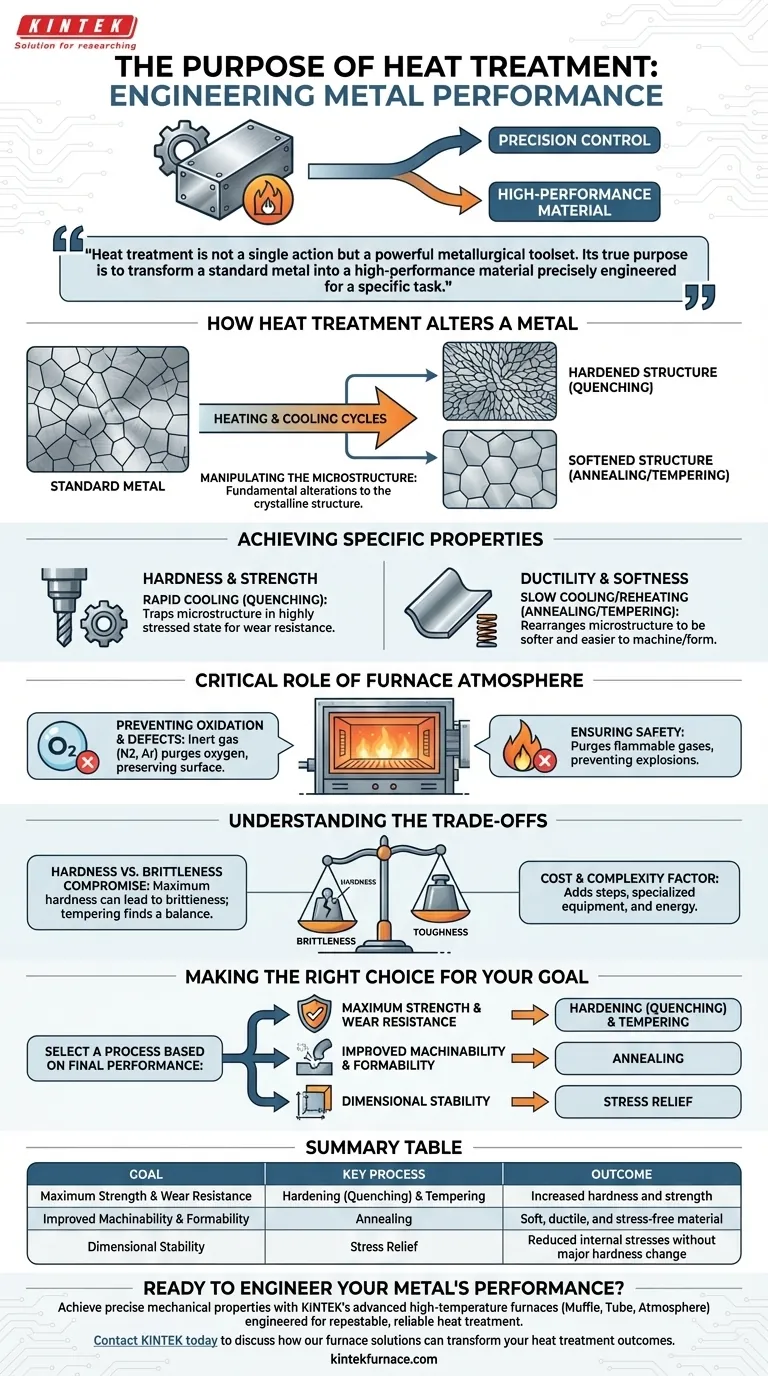

How Heat Treatment Alters a Metal

The changes achieved through heat treatment are not superficial; they are fundamental alterations to the metal's crystalline structure, known as its microstructure.

Manipulating the Microstructure

Heating a metal above a critical temperature dissolves its internal elements into a different crystal structure. The speed at which it is cooled "freezes" or rearranges that structure, locking in the desired properties.

Achieving Hardness and Strength

Rapid cooling, known as quenching, traps the metal's microstructure in a highly stressed, disorganized state. This makes the material significantly harder and stronger, which is ideal for components that must resist wear or deformation.

Restoring Ductility and Softness

Conversely, slow cooling or reheating a previously hardened metal (annealing or tempering) allows the microstructure to rearrange into a more orderly and relaxed state. This process reduces hardness and increases ductility, making the metal easier to machine, form, or bend.

The Critical Role of the Furnace Atmosphere

Successful heat treatment depends on more than just temperature and time; the environment inside the furnace is just as crucial.

Preventing Oxidation and Surface Defects

At high temperatures, oxygen in the air will rapidly react with a metal's surface, causing scaling and discoloration (oxidation). To prevent this, furnaces are filled with an inert atmosphere, typically nitrogen or argon.

This controlled atmosphere purges the oxygen and moisture, ensuring the component's surface finish and dimensional accuracy are preserved.

Ensuring Process Safety

Introducing an inert gas also serves as a critical safety measure. It purges any residual flammable gases from the furnace chamber, preventing the risk of explosion when the furnace is heated.

Understanding the Trade-offs

Heat treatment is a process of compromise. Improving one property often comes at the expense of another.

The Hardness vs. Brittleness Compromise

The most fundamental trade-off is between hardness and brittleness. A metal that has been hardened to its maximum potential is also extremely brittle and may fracture under sudden impact.

Processes like tempering are used after hardening to intentionally reduce some hardness in exchange for increased toughness, finding a balance suitable for the application.

The Cost and Complexity Factor

Heat treatment adds significant steps, time, and cost to a manufacturing process. It requires specialized equipment, precise controls, and additional energy consumption, which must be justified by the required performance of the final part.

Making the Right Choice for Your Goal

Select a heat treatment process based on the final performance you need to achieve.

- If your primary focus is maximum strength and wear resistance: Your goal will be achieved through processes like hardening (quenching) followed by a carefully controlled temper.

- If your primary focus is machinability or formability: Your best approach is a process like annealing, which creates a soft and stress-free state in the material.

- If your primary focus is dimensional stability: Your goal is to use a low-temperature stress relief cycle to remove internal stresses from manufacturing without significantly changing the core hardness.

By understanding these principles, you can leverage heat treatment to transform a simple metal alloy into a precisely engineered component.

Summary Table:

| Goal | Key Process | Outcome |

|---|---|---|

| Maximum Strength & Wear Resistance | Hardening (Quenching) & Tempering | Increased hardness and strength |

| Improved Machinability & Formability | Annealing | Soft, ductile, and stress-free material |

| Dimensional Stability | Stress Relief | Reduced internal stresses without major hardness change |

Ready to Engineer Your Metal's Performance?

Achieving precise mechanical properties requires exact temperature control and a protected furnace atmosphere. KINTEK's advanced high-temperature furnaces, including our Muffle, Tube, and Atmosphere Furnaces, are engineered for repeatable, reliable heat treatment processes.

Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust solutions and strong deep customization capabilities to meet your unique experimental requirements—ensuring your materials perform as intended.

Contact KINTEK today to discuss how our furnace solutions can transform your heat treatment outcomes.

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials