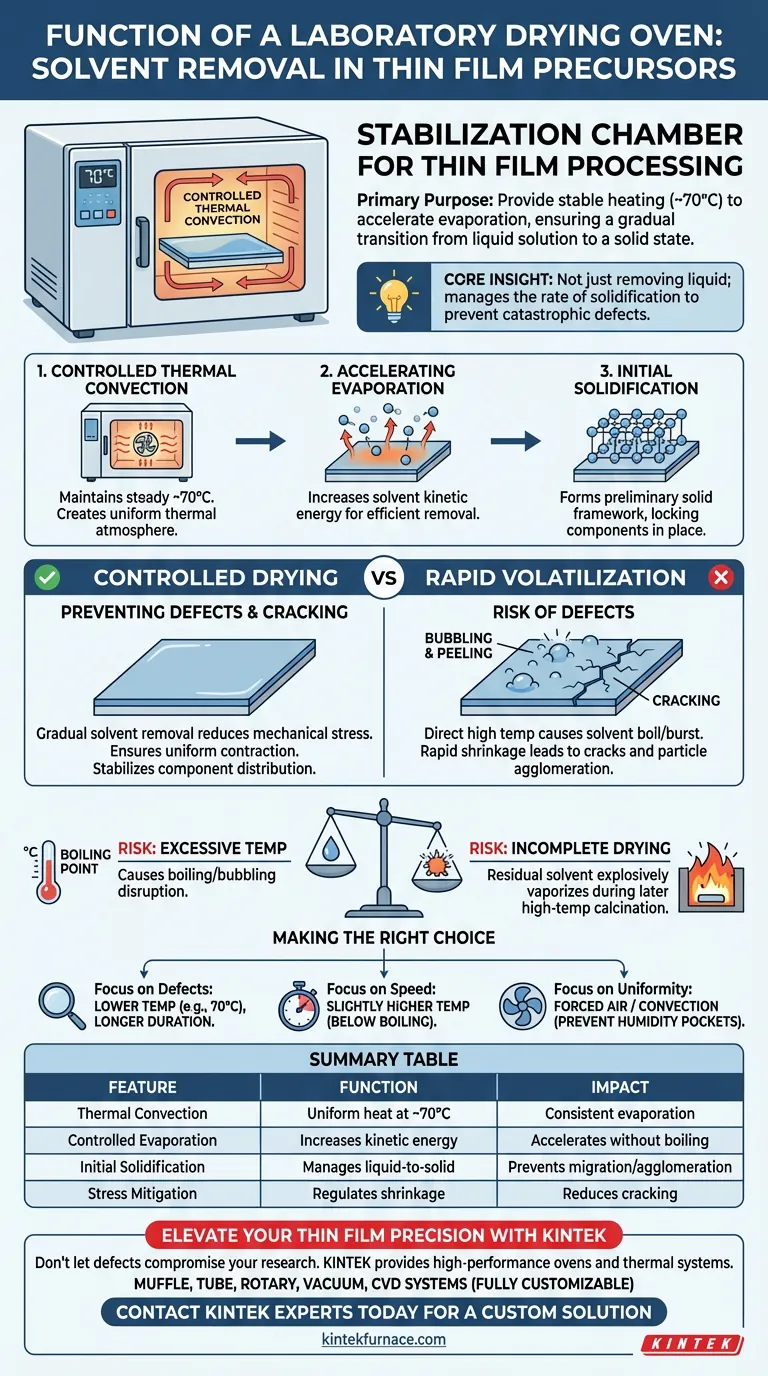

A laboratory drying oven functions as a stabilization chamber during thin film processing. Its primary purpose is to provide a stable heating environment—typically maintained around 70°C—to accelerate the evaporation of solvents from precursor solutions through controlled thermal convection. This ensures the material undergoes a gradual transition from a liquid solution to a solid state.

Core Insight: The drying oven is not merely removing liquid; it is managing the rate of solidification. By controlling the evaporation speed, the oven prevents the catastrophic structural defects, such as cracking or bubbling, that occur if a solvent-heavy precursor is exposed directly to high-temperature annealing.

The Mechanics of Solvent Removal

Controlled Thermal Convection

The oven utilizes thermal convection to maintain a steady temperature, often set near 70°C for thin film applications. This creates a uniform thermal atmosphere that surrounds the substrate.

Accelerating Evaporation

While evaporation occurs naturally at room temperature, the oven accelerates this process to a practical rate. The heat increases the kinetic energy of the solvent molecules, driving them out of the precursor solution efficiently.

Initial Solidification

As the solvent evaporates, the precursor materials begin to bond and form a preliminary solid structure. This phase establishes the physical framework of the thin film, locking the components in place before high-energy processing begins.

Why This Step Defines Film Quality

Preventing Structural Defects

The most critical function of the drying stage is preventing defects caused by rapid volatilization. If a film containing excess solvent is placed directly into a high-temperature furnace, the solvent will boil and burst, leading to bubbling or peeling.

Mitigating Cracking

Controlled drying reduces the mechanical stress within the film as it shrinks. A gradual removal of solvent ensures that the film contracts uniformly, significantly reducing the likelihood of cracks forming across the surface.

Stabilizing Component Distribution

By removing the solvent at a moderate pace, the oven prevents the migration of components within the film. This ensures that the spatial distribution of the precursor remains homogeneous, preventing particle agglomeration or segregation.

Understanding the Trade-offs

The Risk of Excessive Temperature

While heat accelerates drying, setting the oven temperature too high can be detrimental. If the temperature approaches the solvent's boiling point too quickly, it can cause the very disruption (boiling/bubbling) the process is meant to prevent.

The Danger of Incomplete Drying

Conversely, insufficient drying time or temperature leaves residual solvent trapped deep within the film. During subsequent high-temperature calcination, this trapped solvent will vaporize explosively, destroying the film's morphology.

Making the Right Choice for Your Goal

To ensure the success of your thin film deposition, consider how the drying parameters align with your specific precursor chemistry:

- If your primary focus is preventing surface defects: Prioritize a lower temperature (e.g., 70°C) with longer duration to ensure a gentle, non-disruptive evaporation rate.

- If your primary focus is processing speed: You may increase the temperature slightly, but ensure it remains well below the solvent's boiling point to avoid rapid volatilization.

- If your primary focus is uniformity: Ensure your oven utilizes forced air or established convection currents to prevent humidity pockets that cause uneven drying.

The laboratory drying oven acts as the essential gatekeeper, transforming a delicate liquid coating into a robust solid foundation ready for final thermal treatment.

Summary Table:

| Feature | Function in Solvent Removal | Impact on Thin Film Quality |

|---|---|---|

| Thermal Convection | Provides uniform heat distribution at ~70°C | Ensures consistent evaporation across the substrate |

| Controlled Evaporation | Increases kinetic energy of solvent molecules | Accelerates processing without reaching boiling points |

| Initial Solidification | Manages the transition from liquid to solid | Prevents component migration and particle agglomeration |

| Stress Mitigation | Regulates film shrinkage rates | Reduces mechanical stress to prevent surface cracking |

Elevate Your Thin Film Precision with KINTEK

Don't let structural defects like bubbling or cracking compromise your research. KINTEK provides high-performance laboratory drying ovens and specialized thermal systems designed to manage the delicate solidification of your precursors.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific thin film application needs. Ensure your materials have the robust solid foundation they deserve.

Contact KINTEK Experts Today for a Custom Solution

Visual Guide

References

- Daniel Sánchez‐Rodríguez, Jordi Farjas. Kinetic analysis of reversible solid-gas reactions in films: application to the decomposition of CaCO$$_3$$ and BaCO$$_3$$ carbonates. DOI: 10.1007/s10973-024-13318-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the purpose of sintering furnaces? Transform Powders into Strong, Dense Materials

- What role does an industrial box-type resistance furnace play in phosphor conversion? Powering Material Synthesis

- Why is precise temperature control in a vacuum drying oven critical for CoTe@Ti3C2 battery electrodes? Key Insights.

- Why is vacuum freeze-drying necessary for FeNC/MXene catalysts? Preserving 2D Architecture for Peak Performance

- Why use a precision oven for moxa floss samples? Ensure Accurate Air-Drying Basis for Combustion Research

- Why is rapid water quenching necessary after thermal compression? Capture True Microstructures in Medium-Mn Steel

- Why is a secondary calcination furnace required after ball milling? Unlock High-Purity Hydroxyapatite Synthesis

- What role does high-vacuum thermal evaporation equipment play in CsPbBr3 detectors? Optimize Electrode Fabrication