Rapid water quenching is strictly necessary to instantaneously "freeze" the microstructure of medium-manganese steel the moment thermal compression ends. By utilizing extremely high cooling rates, this process prevents the material from undergoing further changes that naturally occur during slower cooling, effectively capturing a snapshot of the high-temperature state.

Thermal compression induces transient changes in steel that are unstable once the physical load is removed. Rapid water quenching preserves the dynamic recrystallization grains and phase distributions as they existed during deformation, ensuring that subsequent analysis reflects the material's true behavior under stress rather than artifacts of the cooling process.

The Mechanics of Microstructural Preservation

Locking in the High-Temperature State

At the precise moment thermal compression concludes, the internal structure of medium-manganese steel is in a highly specific, transient state.

Rapid water quenching acts as a temporal lock. It drops the temperature so quickly that the atoms do not have the thermal energy required to rearrange themselves into a lower-energy, equilibrium state.

Capturing Dynamic Recrystallization

During hot deformation, the steel undergoes a process known as dynamic recrystallization (DRX). This results in specific grain morphologies that tell the story of how the material handled the stress.

If the material is allowed to cool slowly, these grains will change. Quenching ensures the grains observed under a microscope at room temperature look exactly as they did while the material was being compressed at high temperatures.

Maintaining Phase Distributions

Medium-manganese steel relies on complex phase distributions for its properties. These phases are temperature-dependent and will shift if the temperature drops gradually.

Quenching prevents these additional phase transformations. It ensures that the phase distribution you analyze is the one resulting from the compression process, not the cooling process.

The Risks of Slow Cooling

The Onset of Static Recrystallization

If the cooling rate is insufficient, the material immediately begins a process called static recrystallization. This occurs after the deformation load is removed but while the material is still hot.

This "static" change erases the evidence of the "dynamic" changes that occurred during compression. It obscures the data, making it impossible to isolate the effects of the thermal compression itself.

Distorted Data Analysis

The goal of thermal compression testing is often to understand the material's morphology during processing.

Slow cooling introduces a time-lag error. The microstructure observed at room temperature would be a hybrid of deformation effects and cooling effects, rendering the data inaccurate for determining high-temperature behavior.

Understanding the Trade-offs

Thermal Shock and Sample Integrity

While quenching is necessary for microstructural accuracy, the violence of the temperature drop induces significant thermal stress.

This thermal shock can occasionally lead to macroscopic cracking or warping of the sample. While this preserves the microstructure, it can make the physical handling and sectioning of the specimen more difficult.

Sample Preparation Challenges

Rapidly quenched medium-manganese steel often transforms into very hard phases, such as martensite, at room temperature.

This hardness makes the material difficult to cut, grind, and polish for microscopy. You gain data accuracy, but you trade away ease of sample preparation.

Ensuring Data Integrity in Your Experiments

To ensure your observations are valid, align your cooling strategy with your analytical goals:

- If your primary focus is dynamic behavior: You must quench immediately to capture dynamic recrystallization grains without the interference of static restoration.

- If your primary focus is phase mapping: Use rapid cooling to lock in the phase distributions present at the deformation temperature, preventing diffusion-controlled transformations.

Ultimately, rapid quenching is the only method to ensure that your room-temperature observations are a truthful representation of the material's high-temperature reality.

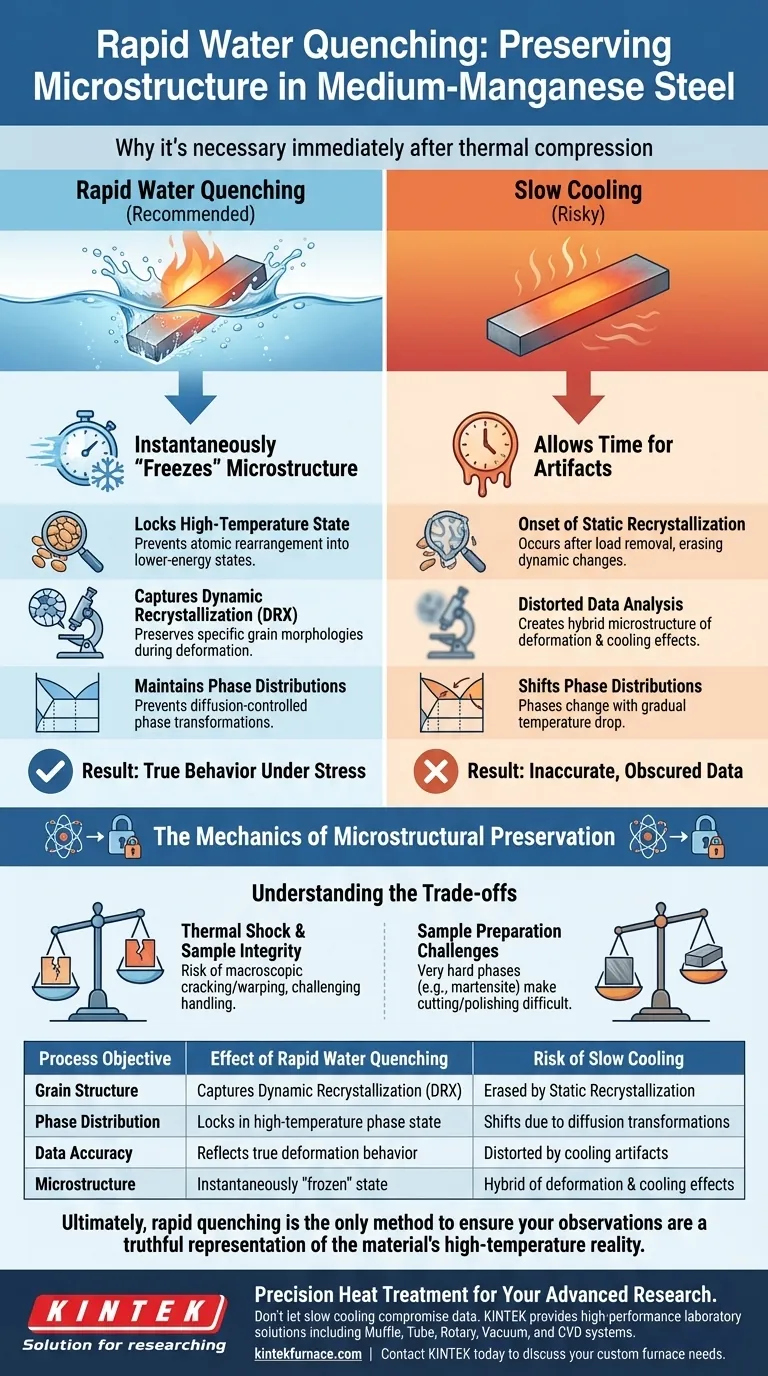

Summary Table:

| Process Objective | Effect of Rapid Water Quenching | Risk of Slow Cooling |

|---|---|---|

| Grain Structure | Captures Dynamic Recrystallization (DRX) | Erased by Static Recrystallization |

| Phase Distribution | Locks in high-temperature phase state | Shifts due to diffusion transformations |

| Data Accuracy | Reflects true deformation behavior | Distorted by cooling artifacts |

| Microstructure | Instantaneously "frozen" state | Hybrid of deformation and cooling effects |

Precision Heat Treatment for Your Advanced Research

Don't let slow cooling rates compromise your experimental data. KINTEK provides high-performance laboratory solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—specifically designed to meet the rigorous demands of thermal processing and material characterization.

Backed by expert R&D and manufacturing, our systems are fully customizable to handle the unique thermal profiles required for medium-manganese steel and other advanced alloys. Ensure microstructural integrity with equipment built for accuracy.

Contact KINTEK today to discuss your custom furnace needs

Visual Guide

References

- Guangshun Guo, Fucheng Zhang. Effects of C and Al Alloying on Constitutive Model Parameters and Hot Deformation Behavior of Medium-Mn Steels. DOI: 10.3390/ma17030732

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is an industrial electric furnace with precise cooling control necessary in lead-bismuth alloy enrichment?

- What is the function of a stable heating environment and ethylene glycol in gold nanoparticle synthesis? Achieve Precision

- What is the purpose of silver paste coating for BCZT ceramics? Ensuring Precision in Electrical Performance Testing

- Why are automated Mass Flow Controllers (MFCs) essential in mixed-gas nitriding? Achieve Process Precision

- Why is continuous removal of carbon essential for methane pyrolysis reactors? Protect Your Reactor's Integrity

- What is a horizontal furnace? A space-saving heating solution for attics and crawl spaces

- What is the purpose of analyzing dust from furnace walls using XRD? Confirm Magnesium Evaporation in AM60 Alloy

- What is the function of rapid quenching after high-temperature heat treatment? Master AlSi10Mg Microstructural Control