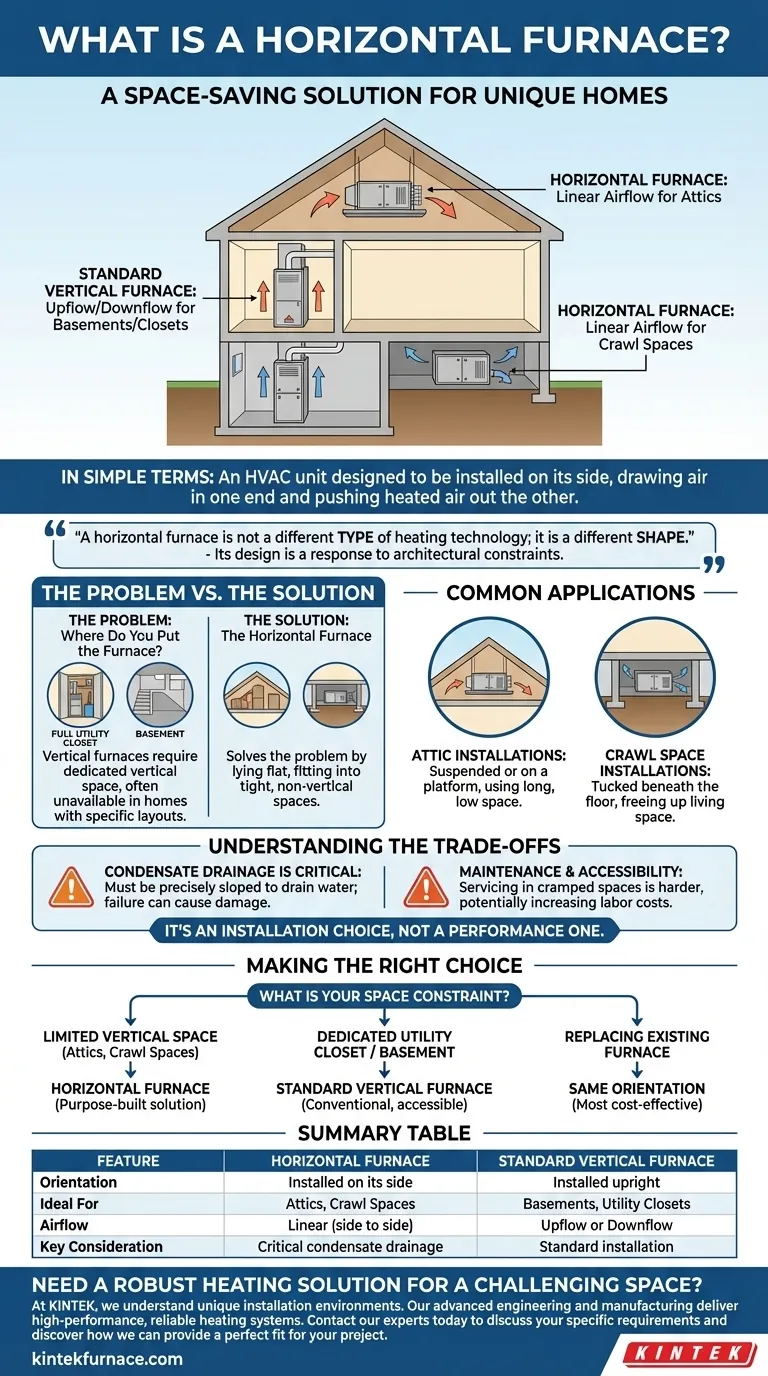

In simple terms, a horizontal furnace is an HVAC unit designed to be installed on its side. Unlike traditional furnaces that stand upright, it draws air in from one end and pushes heated air out the other, making it a specialized solution for homes with specific spatial constraints.

A horizontal furnace is not a different type of heating technology; it is a different shape. Its design is a direct response to the architectural challenge of installing a heating system in a location without the vertical space for a standard furnace.

The Problem: Where Do You Put the Furnace?

The single biggest factor dictating the type of furnace you need is the physical space available for installation. The configuration—upflow, downflow, or horizontal—is chosen to match your home's layout.

The Standard: Vertical Furnaces

Most homes are built with a utility closet, basement, or garage space specifically for a tall, upright furnace.

These are known as upflow (pulling air from the bottom and pushing it up) or downflow (pulling air from the top and pushing it down) units. They are the most common type because they fit in a relatively small footprint.

The Solution: The Horizontal Furnace

A horizontal furnace solves the problem when you have no vertical room. By lying on its side, it can be installed in tight spaces.

The airflow is linear: cool air enters a return vent on one side, passes through the furnace to be heated, and is then blown out the other side into the ductwork.

Common Applications for Horizontal Furnaces

This design makes horizontal furnaces the default choice for specific locations where a vertical unit simply will not fit.

Attic Installations

Attics are a primary location for horizontal units. They can be suspended from the rafters or placed on a dedicated platform, taking advantage of the long, low space without requiring a dedicated closet below.

Crawl Space Installations

For homes built on a slab or with a crawl space instead of a full basement, a horizontal furnace is often the only viable option. It can be tucked away beneath the floor, freeing up living space above.

Understanding the Trade-offs

While the heating performance is the same as a vertical unit, the horizontal orientation introduces unique installation and service considerations.

Condensate Drainage is Critical

High-efficiency furnaces produce water (condensate) as a byproduct of combustion. In a horizontal installation, the unit must be precisely sloped to allow this water to drain properly. Failure to do so can lead to water pooling inside the unit, causing rust, component failure, and potential water damage to your home.

Maintenance and Accessibility

Servicing a furnace in a cramped crawl space or a hot attic is inherently more difficult than working on a unit in an accessible basement closet. This can sometimes lead to higher labor costs for repairs and maintenance. The location can make simple tasks like changing a filter more of a chore.

It's an Installation Choice, Not a Performance One

It is crucial to understand that a horizontal furnace does not heat better or worse than a vertical model with the same specifications. The decision to use one is driven entirely by the constraints of the installation space.

Making the Right Choice for Your Home

Your decision should be guided by your home's architecture and existing setup, not by a perceived benefit of one furnace shape over another.

- If your primary challenge is limited vertical space: A horizontal furnace is the purpose-built solution for attics and crawl spaces.

- If you have a dedicated utility closet or basement: A standard upflow or downflow furnace is the conventional and most easily accessible choice.

- If you are replacing an existing furnace: The most cost-effective solution is almost always to install a new unit with the same orientation as the old one.

Ultimately, the right furnace is the one that fits your home's layout safely and correctly.

Summary Table:

| Feature | Horizontal Furnace | Standard Vertical Furnace |

|---|---|---|

| Orientation | Installed on its side | Installed upright |

| Ideal For | Attics, Crawl Spaces | Basements, Utility Closets |

| Airflow | Linear (side to side) | Upflow or Downflow |

| Key Consideration | Critical condensate drainage | Standard installation |

Need a robust heating solution for a challenging space?

At KINTEK, we understand that every installation environment is unique. Our advanced engineering and in-house manufacturing capabilities allow us to deliver high-performance, reliable heating systems built to withstand demanding conditions. Whether you require a standard unit or a heavily customized solution for a complex space, our expertise ensures optimal performance and durability.

Contact our experts today to discuss your specific requirements and discover how we can provide a perfect fit for your project.

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance