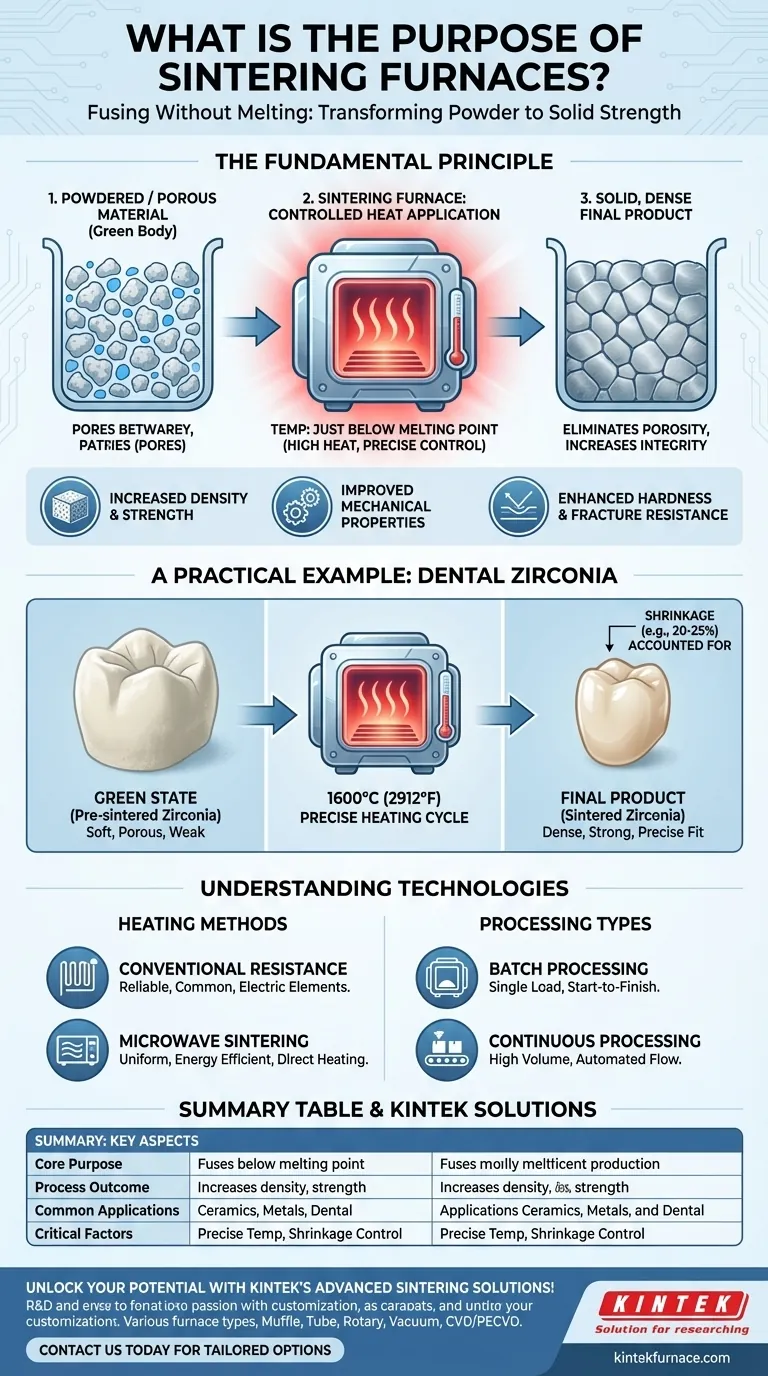

At its core, a sintering furnace is a high-temperature oven that transforms powdered or porous materials into a solid, dense, and strong final product. It achieves this by heating the material to a temperature just below its melting point, causing the individual particles to fuse together, eliminating internal voids and dramatically increasing the material's structural integrity.

The crucial purpose of sintering is not to melt a material, but to use controlled heat to remove porosity and bond particles together. This process is what gives materials like advanced ceramics and certain metals their final strength, density, and hardness.

The Fundamental Principle: Fusing Without Melting

Sintering is a core process in materials science, particularly for materials with extremely high melting points like ceramics or specific metal alloys. The furnace provides the precise thermal environment required for this transformation.

From Powder to Solid Mass

The process begins with a material in a powdered or partially-formed state, often called a "green body." This initial form is porous and mechanically weak.

Inside the furnace, intense heat energizes the atoms within the material. This energy allows atoms to diffuse across the boundaries of adjacent particles, effectively building bridges between them.

Eliminating Porosity

As particles begin to fuse, the empty spaces (pores) between them shrink and close up. This is the primary mechanism for densification.

The furnace's precise temperature control is critical. Too little heat results in incomplete sintering and a weak product. Too much heat risks melting the material, which would destroy its shape and microstructure.

The Result: Increased Density and Strength

By removing porosity, the sintering process significantly increases the material's final density. This directly translates to a dramatic improvement in mechanical properties like hardness, fracture resistance, and overall strength.

A Practical Example: Dental Zirconia

The creation of modern dental crowns and bridges is a perfect illustration of the sintering furnace's purpose.

The "Green State"

A dental crown is first milled from a block of pre-sintered zirconia. At this stage, the material is soft, chalky, and easy to shape but far too weak for clinical use.

The Sintering Cycle

This "green state" crown is placed in a specialized dental sintering furnace. The furnace executes a precise heating and cooling cycle, often reaching temperatures up to 1600°C (2912°F).

The Critical Shrinkage Factor

During the sintering cycle, the zirconia part undergoes significant and predictable shrinkage as its pores are eliminated. This shrinkage, often around 20-25%, must be calculated and accounted for during the initial design and milling phase to ensure the final crown fits perfectly.

Understanding the Technologies and Trade-offs

Sintering furnaces are not a one-size-fits-all solution. The technology used depends on the material, production volume, and desired outcome.

Conventional Resistance Furnaces

These are the most common type, using electric heating elements to generate heat. They are robust, reliable, and well-understood, often configured as horizontal tube furnaces for consistent processing.

Microwave Sintering

A more modern approach uses microwave energy to heat the material directly from within. This can lead to more uniform heating and greater energy efficiency, making it ideal for certain advanced ceramic applications.

Batch vs. Continuous Processing

Furnaces can be designed for batch processing, where a single load is processed from start to finish. They can also be designed for continuous processing, where materials move through different temperature zones on a conveyor, enabling high-volume manufacturing.

Making the Right Choice for Your Goal

The specific application dictates the requirements for the sintering process and the furnace itself.

- If your primary focus is final strength and density: You need a furnace capable of precise, high-temperature cycles to ensure the material is fully consolidated.

- If your primary focus is high-volume production: A continuous furnace configuration that automates material flow is the most efficient choice.

- If your primary focus is energy savings and uniform heating for sensitive materials: Advanced methods like microwave sintering may provide a significant advantage over conventional heating.

Ultimately, a sintering furnace is the critical tool that transforms a fragile, pre-formed object into a functionally robust and durable final product.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Purpose | Fuses powdered or porous materials into solid, dense products by heating below melting point. |

| Process Outcome | Increases density, strength, hardness, and eliminates porosity. |

| Common Applications | Advanced ceramics, metal alloys, dental zirconia crowns and bridges. |

| Furnace Types | Conventional resistance, microwave sintering, batch or continuous processing. |

| Critical Factors | Precise temperature control to avoid melting, predictable shrinkage (e.g., 20-25% for zirconia). |

Unlock the full potential of your materials with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for enhancing strength, boosting production volume, or achieving energy efficiency. Contact us today to discuss how our tailored furnace options can drive your innovations forward!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns