The primary advantage of Flash Lamp Annealing (FLA) is the ability to decouple film crystallization from substrate heating. While traditional muffle furnaces heat the entire assembly uniformly—often warping or melting sensitive substrates—FLA utilizes sub-millisecond, high-energy pulses to rapidly heat the thin film to 600–800°C. This process occurs so quickly that thermal conduction is delayed, keeping the substrate temperature safely below 400°C.

Core Takeaway FLA solves the thermal incompatibility between high-performance films and low-temperature substrates. By delivering instantaneous, selective energy, it enables the growth of piezoceramic films on low-melting-point glass without causing the deformation associated with the prolonged heating of traditional furnaces.

The Mechanics of Rapid Crystallization

Sub-Millisecond Energy Pulses

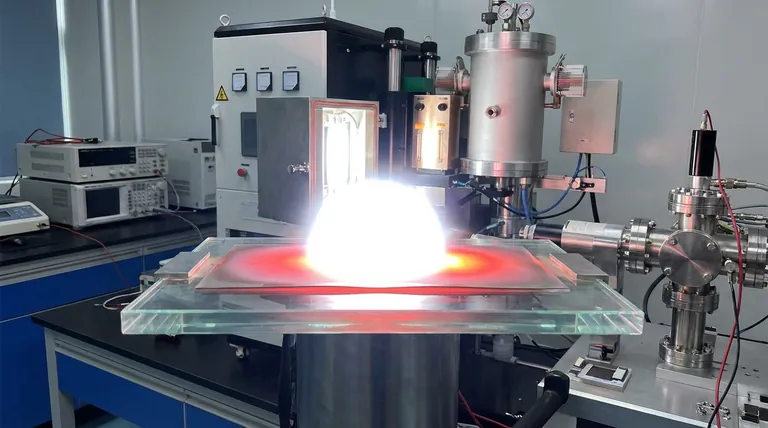

FLA equipment uses xenon lamps to generate extremely short pulses of energy. These pulses last less than a millisecond, delivering a concentrated burst of heat.

Selective Absorption

Unlike a furnace that heats the air and chamber walls, FLA relies on selective light absorption. The thin film absorbs the photonic energy directly, converting it into heat instantly.

Achieving High Peak Temperatures

This method allows the film to reach crystallization temperatures of approximately 600–800°C. This is sufficient to induce the necessary phase changes for high-performance piezoelectric properties.

Solving the Substrate Constraint

Overcoming the "Glass Ceiling"

Traditional muffle furnaces require prolonged heating to achieve crystallization. If you attempt to reach 600°C in a standard furnace, a glass substrate will likely deform or melt due to the sustained thermal load.

Utilizing Thermal Delay

FLA exploits the principle of thermal conduction delay. Because the heating duration is so short, the heat generated in the film does not have time to conduct fully into the substrate.

Preserving Substrate Integrity

Consequently, the substrate remains below 400°C. This capability is critical for in-situ growth on cost-effective or functional low-melting-point glass substrates that cannot survive traditional annealing.

Understanding the Trade-offs

The Value of Slow Annealing

While FLA excels at speed and substrate protection, the traditional programmable muffle furnace offers different benefits. It provides precise temperature cycle control, typically operating effectively between 200°C and 300°C for specific applications.

Managing Internal Stress

The slow, controlled nature of a muffle furnace allows for gradual atomic migration. This can help minimize internal thermal stress and eliminate structural defects, resulting in a dense and uniform film surface.

Crystallinity and Phase Transition

For substrates that can withstand the heat, or for processes requiring lower temperatures, muffle furnaces significantly promote the phase transition from an amorphous state to a crystalline phase. They ensure consistent grain size through steady thermal application.

Making the Right Choice for Your Goal

To select the correct annealing method, you must prioritize either substrate protection or stress minimization.

- If your primary focus is Substrate Compatibility: Choose Flash Lamp Annealing (FLA) to grow high-temperature films on heat-sensitive materials like glass without deformation.

- If your primary focus is Film Density and Stress Reduction: Choose a Programmable Muffle Furnace (if substrate permits) to minimize defects through precise, slow-cycle thermal control.

Ultimately, FLA is the enabling technology for combining high-performance ceramics with low-cost, low-temperature substrates.

Summary Table:

| Feature | Flash Lamp Annealing (FLA) | Traditional Muffle Furnace |

|---|---|---|

| Heating Speed | Sub-millisecond pulses | Slow, gradual cycles |

| Substrate Impact | Minimal (stays < 400°C) | High (heats entire assembly) |

| Target Temp | 600–800°C (film selective) | Uniform chamber temperature |

| Key Benefit | Use with low-temp substrates | Stress reduction & film density |

| Best For | Glass/flexible substrates | High-density crystallization |

Revolutionize Your Material Processing with KINTEK

Whether you need the rapid, selective energy of advanced annealing or the precision of controlled thermal cycles, KINTEK provides the expertise to elevate your lab's capabilities. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique thin-film and ceramic research requirements.

Ready to overcome thermal constraints? Contact KINTEK today to find the perfect high-temperature solution for your lab!

References

- Longfei Song, Sebastjan Glinšek. Crystallization of piezoceramic films on glass via flash lamp annealing. DOI: 10.1038/s41467-024-46257-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Spark Plasma Sintering SPS Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary purpose of the 600°C annealing treatment? Optimize Silver-Coated Ceramic Performance

- What are the technical advantages of using a six-zone resistance heating furnace in VGF-VB? Unlock Precision Growth

- What is Joule Heating and how does it relate to induction heating? Master the Physics of Contactless Heating

- What is the role of a customized drying station with nitrogen purging? Optimize Polymer Blend Membrane Processing

- Why is a laboratory oven used for constant temperature treatment of celadon? Ensure Peak Measurement Accuracy

- How does the addition of RhCl3 facilitate the synthesis of RhSeCl crystals? Unlock High-Quality Crystal Growth

- What occurs during the recrystallization stage of annealing? Restore Ductility and Reset Microstructure

- What are the advantages of SLRP compared to traditional high-temperature furnaces? Revolutionizing UHTC Coatings