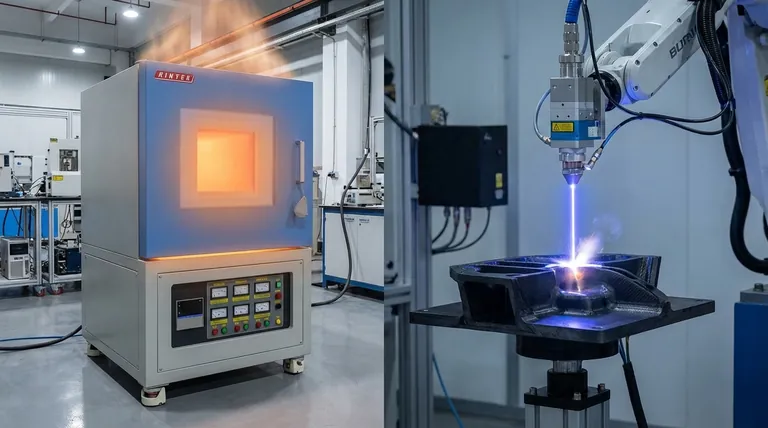

The primary advantage of Selective Laser Reactive Pyrolysis (SLRP) is its ability to decouple the ceramization process from the thermal limitations of the substrate. By using a focused laser for in-situ deposition, SLRP eliminates the reliance on bulky, high-energy traditional furnaces and their associated long preheating times. This approach delivers rapid ceramization directly onto materials like carbon-carbon composites without subjecting the entire component to prolonged, damaging high temperatures.

Core Takeaway Traditional manufacturing requires heating the entire assembly, which wastes energy and risks degrading temperature-sensitive substrates. SLRP solves this by applying precise, localized heat only where necessary, enabling the rapid, energy-efficient creation of thermal protection systems on complex geometries.

Thermal Management and Substrate Integrity

Preventing Prolonged Thermal Exposure

Traditional high-temperature electric furnaces operate by heating the entire processing environment. This subjects the substrate—the material being coated—to extreme heat for the duration of the cycle.

SLRP fundamentally changes this dynamic. It allows for rapid ceramization, meaning the ceramic coating is formed quickly without "soaking" the underlying material in heat. This prevents the substrate from degrading due to prolonged exposure to high temperatures.

In-Situ Selective Deposition

SLRP utilizes an additive manufacturing approach to deposit coatings. This process occurs in-situ, meaning the coating is synthesized and bonded directly on the part in real-time.

This is particularly beneficial for substrates like carbon-carbon (C/C) composites. The laser targets only the specific areas requiring coating, leaving the rest of the material unaffected by thermal stress.

Operational Efficiency

Eliminating Preheating Cycles

A major inefficiency of traditional furnaces is the time required to reach operating temperature. Large furnaces require significant "ramp-up" periods before processing can even begin.

SLRP removes this bottleneck entirely. Because the laser provides instant, localized energy, there is no need for long preheating times, drastically reducing the total manufacturing cycle time.

Reducing Energy Consumption

Traditional methods are characterized as "high-energy-consuming" because they must maintain a massive volume of space at ultra-high temperatures.

By switching to a selective laser source, manufacturers stop heating the empty space around the part. Energy is directed solely into the reaction zone, offering a far more energy-efficient solution for producing Ultra-High Temperature Ceramics.

Design and Geometric Flexibility

Enabling Complex Geometries

Furnace-based coatings can sometimes struggle with uniformity on intricate parts, or require complex fixturing to ensure even exposure.

SLRP is inherently an additive manufacturing solution. This flexibility allows for the precise coating of complex geometries that might be difficult or impossible to process effectively using a "bulk heating" method.

Considerations and Trade-offs

Process Nature vs. Bulk Processing

While SLRP offers superior precision, it is important to recognize the shift in processing methodology.

Traditional furnaces are "bulk" processors, treating the entire surface area simultaneously via ambient heat. SLRP is "selective," implying a directed line-of-sight process where the laser must trace the deposition area.

Equipment Footprint

The primary reference highlights that SLRP eliminates "bulky" furnaces.

However, this implies a trade-off in equipment complexity. You are exchanging a large, passive heating vessel for a sophisticated, active laser system that requires precise control to achieve the desired coverage on complex shapes.

Making the Right Choice for Your Goal

SLRP represents a shift from passive heating to active, precision manufacturing. To decide if this technology fits your specific application, consider your primary constraints.

- If your primary focus is Substrate Preservation: SLRP is the superior choice because it prevents prolonged exposure to high temperatures, protecting sensitive materials like C/C composites.

- If your primary focus is Energy and Speed: SLRP offers the greatest advantage by eliminating long furnace preheating cycles and focusing energy only where it is needed.

SLRP transforms coating from a brute-force thermal event into a precise, energy-efficient manufacturing step.

Summary Table:

| Feature | Traditional High-Temp Furnaces | Selective Laser Reactive Pyrolysis (SLRP) |

|---|---|---|

| Heating Method | Bulk processing (entire chamber) | Selective, localized laser heating |

| Substrate Impact | Risk of thermal degradation | Minimal stress; prevents heat damage |

| Processing Speed | Long preheating and cooling cycles | Rapid, instant ceramization |

| Energy Efficiency | High consumption (heating empty space) | Low consumption (energy focused on reaction) |

| Geometric Flexibility | Limited by uniform heat distribution | High (ideal for complex additive shapes) |

Optimize Your Thermal Protection Systems with KINTEK

Transitioning from traditional bulk heating to precision manufacturing requires the right technological partner. Whether you are working with carbon-carbon composites or developing complex ceramic geometries, KINTEK provides the high-performance solutions you need.

Why Choose KINTEK?

- Advanced R&D: Backed by expert manufacturing for Muffle, Tube, Rotary, and Vacuum systems.

- Customizable Solutions: CVD systems and lab high-temp furnaces tailored to your unique research or production needs.

- Efficiency & Precision: Designed to meet the rigorous demands of Ultra-High Temperature Ceramic (UHTC) applications.

Contact our specialists today to explore how our customizable furnace systems can enhance your lab's efficiency and material integrity.

Visual Guide

References

- Shalini Rajpoot, Chengying Xu. Synthesis of hafnium carbide (HfC) via one‐step selective laser reaction pyrolysis from liquid polymer precursor. DOI: 10.1111/jace.20650

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What critical environmental conditions does a high-temperature recrystallization annealing furnace provide? Maximize Steel Strength

- What are the advantages of using electron bombardment heating systems for Niobium? Achieve Industrial Fidelity

- How does the combination of a nitrogen atmosphere and magnetic stirring benefit the dissolution stage? | KINTEK

- How does a gas evolution analysis system monitor gas release? Optimize Your Casting Integrity

- How do industrial cameras and CNN improve surface defect detection? Revolutionize QC with 95%+ Accuracy

- How does a benchtop industrial oven improve efficiency? Boost Energy Savings and Space Use

- Why is high-temperature hydrogen reduction used for HI decomposition catalysts? Boost Efficiency and Surface Purity

- Why is a laboratory oven used for constant temperature treatment of celadon? Ensure Peak Measurement Accuracy