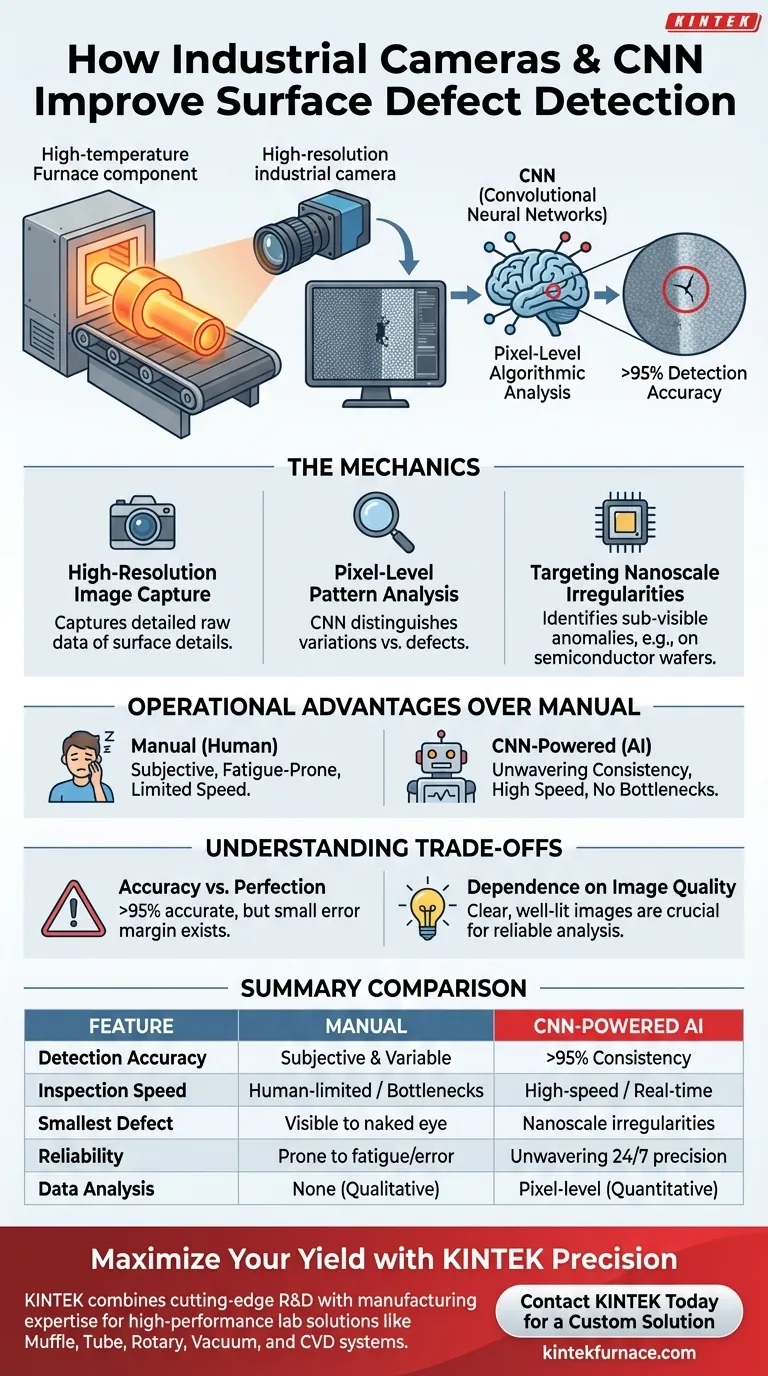

Industrial cameras paired with Convolutional Neural Networks (CNNs) revolutionize defect detection by combining high-resolution imaging with pixel-level algorithmic analysis to achieve detection accuracy exceeding 95%. This integration allows for the rapid identification of surface anomalies and nanoscale irregularities that are often invisible to the naked eye, ensuring a level of consistency and speed that manual inspection cannot match.

Automated inspection systems mitigate human error by utilizing deep learning algorithms to analyze components at a pixel level. This approach fundamentally shifts quality control from a subjective, labor-intensive process to a data-driven operation that significantly reduces scrap rates and missed defects.

The Mechanics of Automated Inspection

High-Resolution Image Capture

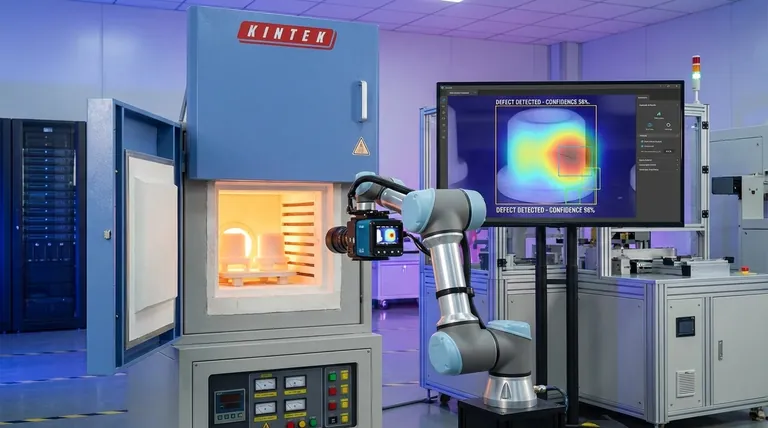

The foundation of this system lies in industrial cameras capable of capturing high-resolution images of furnace components.

These cameras provide the raw data necessary for detailed analysis, ensuring that even the most minute surface details are recorded for processing.

Pixel-Level Pattern Analysis

Once images are captured, CNN algorithms process the visual data.

Unlike simple threshold-based sensors, these algorithms perform pixel-level pattern analysis. This allows the system to distinguish between acceptable variations and actual defects with high precision.

Targeting Nanoscale Irregularities

The technology is particularly adept at handling complex components, such as semiconductor wafers or electronic parts often processed in high-temperature environments.

It can identify nanoscale irregularities and subtle surface anomalies that would typically evade standard inspection tools.

Operational Advantages Over Manual Methods

Eliminating Subjectivity

Manual inspection is prone to fatigue and inconsistency.

CNN-driven systems offer unwavering consistency, applying the exact same criteria to every single component, regardless of volume or time of day.

Speed and Throughput

The automated nature of CNN processing allows for detection speeds that far exceed human capabilities.

This enables manufacturers to maintain high production throughput without creating bottlenecks at the quality control stage.

Understanding the Trade-offs

Accuracy vs. Perfection

While these systems achieve an impressive detection accuracy of over 95%, it is important to recognize that they are not infallible.

There remains a small margin of error, which means critical applications may still require a secondary review process for edge cases.

Dependence on Image Quality

The efficacy of the CNN is entirely dependent on the quality of the input data.

If the industrial cameras fail to capture clear, well-lit images due to environmental factors in the manufacturing floor, the pixel-level analysis will yield unreliable results.

Optimizing Quality Control Strategies

To maximize the benefits of this technology for your production line, consider your specific inspection goals:

- If your primary focus is Precision: Leverage CNNs for their ability to detect nanoscale irregularities in high-value components like semiconductor wafers.

- If your primary focus is Efficiency: Implement this system to replace manual bottlenecks, utilizing its superior speed to lower scrap rates and missed defects.

By integrating industrial cameras with deep learning algorithms, manufacturers secure a scalable, high-accuracy solution that protects both product quality and the bottom line.

Summary Table:

| Feature | Manual Inspection | CNN-Powered AI Inspection |

|---|---|---|

| Detection Accuracy | Subjective & Variable | Over 95% Consistency |

| Inspection Speed | Human-limited / Bottlenecks | High-speed / Real-time |

| Smallest Defect | Visible to naked eye | Nanoscale irregularities |

| Reliability | Prone to fatigue/error | Unwavering 24/7 precision |

| Data Analysis | None (Qualitative) | Pixel-level (Quantitative) |

Maximize Your Yield with KINTEK Precision

Don't let manual inspection bottlenecks and scrap rates compromise your production excellence. KINTEK combines cutting-edge R&D with manufacturing expertise to provide high-performance lab solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems.

Whether you are processing semiconductor wafers or advanced ceramics, our customizable high-temperature furnaces are designed to meet your most rigorous quality standards. Partner with us to achieve the precision and consistency your facility demands.

Contact KINTEK Today for a Custom Solution

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a batch furnace differ from a continuous furnace? Choose the Right Furnace for Your Production Needs

- What role does a laboratory blast drying oven play in the preparation of Ti-doped Mn3O4? Optimize Your Precursor Quality

- Why is a high flow rate of synthetic air maintained during magnetite oxidation? Ensure Accurate Kinetic Modeling

- Why is a pre-heated oxygen blowing system essential for chalcopyrite ignition? Ensure Precise Flash Smelting Simulation

- What is the purpose of performing a 600 degree Celsius annealing treatment? Enhance AZO Thin Film Stability

- Why is the addition of silver nanoparticles critical for Ag2Se films? Unlock High Thermoelectric Performance

- Why does vacuum quality impact carbon chain yield? Essential Standards for High-Yield Synthesis

- What is the specific function of laboratory electric heating devices in solid-state hydrogen storage? Optimize Thermal Management