The integrity of your high vacuum environment is the primary safeguard against the chemical destruction of synthesized carbon chains. In vacuum induction or ceramic furnaces, residual gas pressure—specifically oxygen—directly determines whether you create new material or simply burn away your feedstock. If the vacuum is insufficient, high temperatures accelerate the reaction between these gases and the carbon, destroying chains faster than they form.

Maximizing yield requires tipping the scale between formation and destruction. A vacuum level superior to 10^-5 mbar is required to suppress residual oxygen, preventing it from etching away the host nanotubes and the newly formed carbon chains.

The Chemistry of Yield Loss

The Role of Residual Oxygen

Even in a controlled furnace environment, trace amounts of gas remain. Residual oxygen is the most detrimental factor in this process.

At the high temperatures required for synthesis, oxygen becomes highly reactive. It does not simply exist alongside your materials; it actively attacks them.

The Etching Mechanism

This attack manifests as oxidative etching. The residual oxygen reacts with the carbon structures, effectively burning them away.

This destruction is twofold: it destroys the host nanotubes required for the process and the newly formed carbon chains themselves.

If the rate of this etching exceeds the rate of synthesis, your net yield will effectively be zero.

The Critical Vacuum Threshold

The 10^-5 mbar Standard

To ensure a net increase in production, you must achieve a specific vacuum benchmark. Maintaining a pressure lower than 10^-5 mbar is crucial.

This threshold represents the tipping point where the concentration of residual gas is low enough to mitigate rapid oxidation.

Balancing Formation Rates

Synthesis in this context is a competition between two opposing forces: chain formation and chain destruction.

A high-quality vacuum slows the destruction rate significantly. This allows the formation rate to dominate, resulting in a successful, high-yield production run.

Understanding the Risks and Trade-offs

The Sensitivity of Carbon Nanostructures

It is critical to understand that carbon chains and nanotubes are far more sensitive to environmental conditions than bulk materials.

While a standard vacuum might protect a graphite mold from gross oxidation, it may not be sufficient for these delicate nanostructures.

The "Invisible" Failure Mode

A common pitfall is assuming that because the furnace reaches temperature, synthesis is occurring.

If the vacuum level drifts above 10^-5 mbar, you may still consume energy and time, but the product will be "etched" out of existence as quickly as it is made.

Making the Right Choice for Your Process

To ensure you are synthesizing material rather than destroying it, apply the following standards to your operation:

- If your primary focus is Maximizing Yield: Ensure your vacuum system is rated for and consistently sustains pressures lower than 10^-5 mbar throughout the entire heating cycle.

- If your primary focus is Process Troubleshooting: Investigate leaks or outgassing sources that may be introducing residual oxygen, as this is the specific agent responsible for low yields.

Control the vacuum, and you control the survival of the carbon chain.

Summary Table:

| Parameter | Influence on Carbon Chain Synthesis |

|---|---|

| Critical Vacuum Level | Must be < 10^-5 mbar to prevent oxidative etching |

| Primary Contaminant | Residual Oxygen (causes chemical destruction of chains) |

| Host Material Risk | Host nanotubes are etched away if vacuum is insufficient |

| Reaction Dynamics | Synthesis (Formation) vs. Oxidation (Destruction) |

| Failure Mode | Invisible yield loss where material burns as it forms |

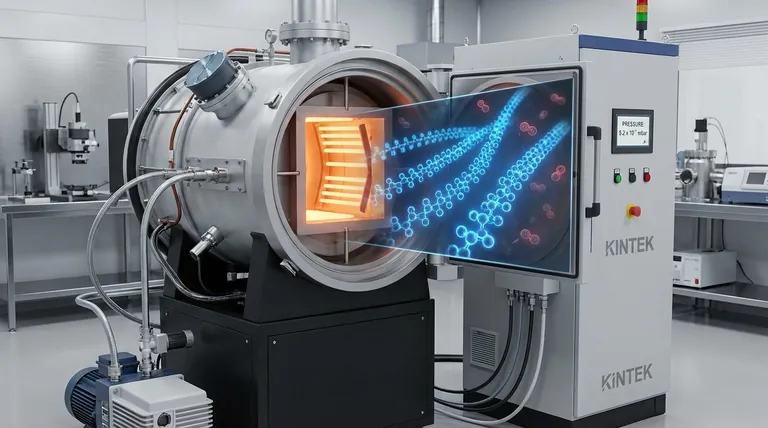

Maximize Your Synthesis Yield with KINTEK Precision

Don't let residual oxygen destroy your research. At KINTEK, we understand that the survival of delicate carbon nanostructures depends on absolute atmospheric control. Backed by expert R&D and manufacturing, we offer high-performance Vacuum Induction and Ceramic Furnaces engineered to sustain the rigorous pressures required for advanced material synthesis.

Whether you need standard or fully customizable Muffle, Tube, Rotary, Vacuum, or CVD systems, KINTEK provides the reliability necessary to tip the scales in favor of formation over destruction.

Ready to upgrade your lab's high-temperature capabilities? Contact our technical experts today to find the perfect solution for your unique needs.

Visual Guide

References

- Clara Freytag, Thomas Pichler. Systematic Optimization of the Synthesis of Confined Carbyne. DOI: 10.1002/smtd.202500075

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why is high-temperature homogenization necessary for refractory alloy thermal expansion tests? Ensure Data Precision.

- What are the advantages of the Laser Hearth Method for Zirconia? Achieve High Purity & Density for Advanced Research

- Why is dual heat treatment required for SnO2 nanoparticles? Optimize Oxidation for Superior Performance

- What is the significance of using high-temperature heating equipment to reach 1250°C for alloys? Stress Test Excellence

- Why is the addition of silver nanoparticles critical for Ag2Se films? Unlock High Thermoelectric Performance

- What role does natural zeolite play as a catalyst in LDPE pyrolysis? Boost Yield and Efficiency in Plastic Recycling

- What is the function of PVA binder and high-pressure compression in SSBSN? Optimize Your Ceramic Green Body Preparation

- Why is temperature gradient management necessary for high-temperature impedance measurements? Master Thermal Precision