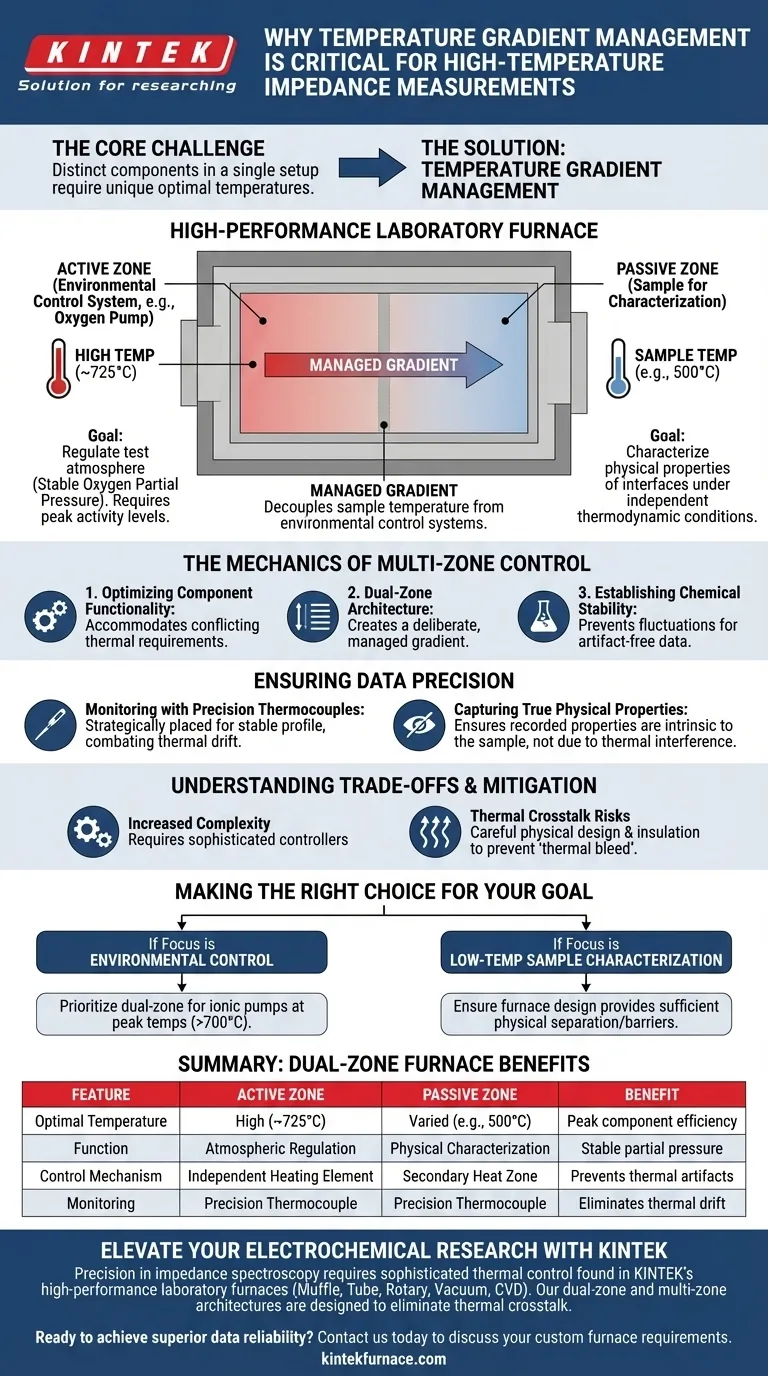

Temperature gradient management is strictly necessary because it permits distinct components within a single experimental setup to operate at their unique, optimal temperatures simultaneously. In high-temperature impedance measurements, this capability allows environmental control systems—such as oxygen pumps—to function at high efficiency without thermally compromising the sample being tested at a different specific temperature.

By decoupling the temperature of the sample from the temperature of the environmental control systems, researchers can maintain a stable chemical atmosphere while accurately characterizing the physical properties of interfaces under independent thermodynamic conditions.

The Mechanics of Multi-Zone Control

Optimizing Component Functionality

Complex impedance setups often require active components, such as oxygen pumps, to regulate the test atmosphere.

These components frequently require high temperatures to achieve necessary activity levels for ion transport, often around 725 °C.

However, the sample material itself may require testing at a significantly lower temperature, such as 500 °C.

The Role of Dual-Zone Architecture

To accommodate these conflicting thermal requirements, high-performance furnaces utilize dual-zone temperature control.

This architecture creates a deliberate, managed gradient within the furnace chamber.

It enables the "active" region to remain hot enough for environmental regulation while the "passive" sample region stays at the target test temperature.

Establishing Chemical Stability

A primary goal of this thermal management is ensuring a stable oxygen partial pressure environment.

By keeping the oxygen pump in its high-activity zone, the system can maintain precise atmospheric conditions regardless of the sample's temperature.

This stability is critical for preventing chemical fluctuations that could introduce artifacts into the impedance data.

Ensuring Data Precision

Monitoring with Precision Thermocouples

Implementing a temperature gradient requires rigorous monitoring to ensure the gradient profile is stable and known.

Precision thermocouples are placed strategically to monitor both the high-heat active zone and the sample zone.

This feedback loop allows the furnace controllers to combat thermal drift and lock in the desired gradient.

Capturing True Physical Properties

Impedance spectroscopy is highly sensitive to the thermodynamic state of the material interfaces.

If the sample temperature fluctuates due to proximity to the oxygen pump, the thermodynamic conditions change, skewing the data.

Gradient management ensures the physical properties recorded are intrinsic to the sample at the intended test temperature, not a result of thermal interference.

Understanding the Trade-offs

Increased System Complexity

While necessary for high-fidelity data, managing temperature gradients introduces significant complexity to the equipment setup.

It requires multiple independent heating elements and sophisticated controllers rather than a single set-point thermostat.

Thermal Crosstalk Risks

Even with dual-zone control, heat naturally migrates from high-temperature zones to lower ones.

Improper spacing or insulation between the oxygen pump and the sample can lead to "thermal bleed," where the sample is inadvertently heated above its set point.

This requires careful physical design of the furnace to maintain the integrity of the gradient.

Making the Right Choice for Your Goal

To maximize the accuracy of your impedance measurements, you must align your furnace capabilities with your experimental constraints.

- If your primary focus is environmental control: Prioritize a dual-zone system that allows ionic pumps to operate at peak temperatures (e.g., >700 °C) to ensure a stable oxygen partial pressure.

- If your primary focus is low-temperature sample characterization: Ensure your furnace design provides sufficient physical separation or thermal barriers to prevent heat from the environmental control zone from affecting the sample.

Precision in thermal management is the defining factor that transforms a standard furnace into a high-performance tool for reliable electrochemical analysis.

Summary Table:

| Feature | Active Zone (Oxygen Pump) | Passive Zone (Sample) | Benefit |

|---|---|---|---|

| Optimal Temperature | High (~725°C) | Varied (e.g., 500°C) | Peak component efficiency |

| Function | Atmospheric Regulation | Physical Characterization | Stable partial pressure |

| Control Mechanism | Independent Heating Element | Secondary Heat Zone | Prevents thermal artifacts |

| Monitoring | Precision Thermocouple | Precision Thermocouple | Eliminates thermal drift |

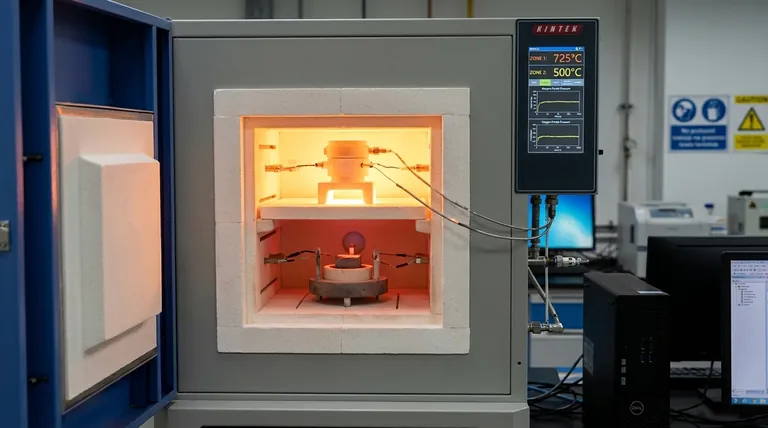

Elevate Your Electrochemical Research with KINTEK

Precision in impedance spectroscopy requires more than just heat; it requires the sophisticated thermal control found in KINTEK’s high-performance laboratory furnaces.

Backed by expert R&D and manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique research needs. Our dual-zone and multi-zone furnace architectures are designed to eliminate thermal crosstalk, ensuring your samples remain at the exact target temperature while environmental control systems operate at peak efficiency.

Ready to achieve superior data reliability? Contact us today to discuss your custom furnace requirements.

Visual Guide

References

- Claudia Steinbach, Jürgen Fleig. The Oxygen Partial Pressure Dependence of Space Charges at SrTiO<sub>3</sub>|Mixed Ionic Electronic Conducting Oxide Heterojunctions. DOI: 10.1002/smtd.202500728

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the purpose of the two-step heat treatment process? Optimize Zirconolite-Based Glass-Ceramic Matrices

- Why use liquid nitrogen freezing & vacuum freeze-drying for cement and biomass hydration? Preserve Microstructure Now

- What are the functions of a programmed temperature rise experimental system? Master Coal Pre-Oxidation Research

- How do industrial molds and 10 MPa pressure impact PEEK quality? Unlock Superior Density & Structural Integrity

- Why is a high-temperature reaction chamber with a platinum strip used for in-situ XRD analysis of calcium ferrites?

- What is the function of the circulation pump in a salt bath furnace? Master Sorbite Transformation Quality

- What is the purpose of introducing high-purity argon gas into an immersed probe? Enhance Melt Analysis Accuracy

- Why must Ru/GNK catalysts undergo vacuum drying? Ensure Peak Performance with Safe Desorption