High-temperature homogenization heat treatment is a prerequisite for thermal expansion testing because it eliminates the structural and chemical inconsistencies inherent in as-cast refractory alloys. By removing dendritic segregation and relieving internal residual stresses, this process ensures that the test results reflect the material's true properties rather than artifacts of the manufacturing process.

Core Takeaway: To obtain a stable Coefficient of Thermal Expansion (CTE), an alloy must be chemically and mechanically uniform. Homogenization neutralizes the "history" of the casting process, minimizing hysteresis and revealing the intrinsic thermophysical parameters required for accurate coating design and system integration.

Addressing the As-Cast Microstructure

Eliminating Dendritic Segregation

Refractory alloys solidify in a way that creates chemical unevenness, known as dendritic segregation.

During the casting process, different elements solidify at different times, creating a non-uniform composition across the microstructure. Homogenization promotes the diffusion of chemical components, smoothing out these gradients to create a uniform material.

Relieving Internal Residual Stresses

The rapid or uneven cooling rates during casting lock internal residual stresses into the alloy.

If these stresses are present during thermal expansion testing, they will release or distort the material as it heats up. This distortion interferes with the measurement, producing data that conflates thermal expansion with stress relief.

Modifying Carbide Morphology

In addition to chemical balancing, the physical structure of precipitates matters.

Holding the material at high temperatures (such as 900°C) allows for the morphological transformation or partial dissolution of irregular carbides. This ensures that hard phases within the alloy do not unpredictably influence the expansion behavior.

Achieving Data Stability and Accuracy

Establishing a Stable CTE

The primary goal of testing is to determine the alloy's Coefficient of Thermal Expansion (CTE).

Without homogenization, the CTE may fluctuate due to the shifting microstructure described above. A homogenized sample exhibits a stable CTE, providing a reliable baseline for engineering applications.

Minimizing the Hysteresis Loop

Thermal expansion tests often show a "hysteresis loop," where the material's expansion path during heating differs from its contraction path during cooling.

A large loop indicates structural instability or phase changes occurring during the test. Homogenization minimizes this hysteresis, confirming that the material is stable and the measurements are repeatable.

Environmental Controls and Trade-offs

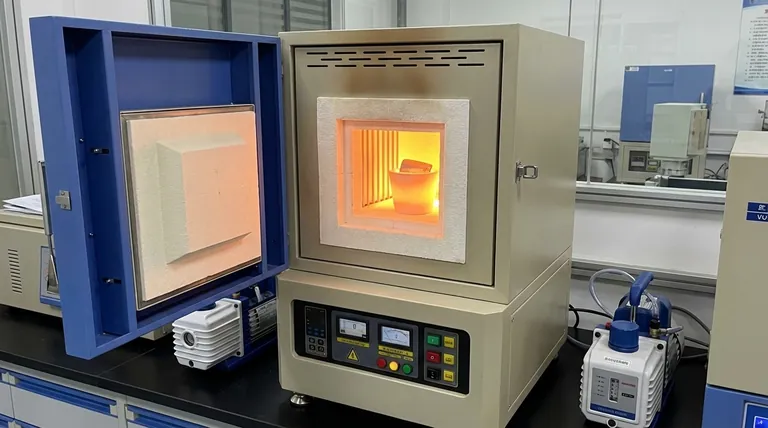

The Critical Role of Vacuum Environments

It is not enough to simply heat the material; the environment must be controlled to prevent degradation.

Utilizing a high-temperature vacuum furnace prevents the alloy from absorbing impurity gases like oxygen, nitrogen, and hydrogen. Preventing this absorption is vital to avoid material embrittlement, which would skew mechanical data and potentially ruin the sample.

The Trade-off of Skipping Treatment

Attempting to save time by skipping homogenization yields data that represents the casting process, not the material.

This "false" data creates a disconnect when designing coatings or mating parts. If you design a system based on as-cast expansion data, the actual components (which will eventually homogenize in service) may fail due to thermal mismatch.

Making the Right Choice for Your Goal

To ensure your thermal expansion data effectively guides your engineering decisions, apply the following context to your testing protocols:

- If your primary focus is Coating Design: You must perform homogenization to determine the intrinsic thermophysical parameters of the substrate, ensuring the coating will not delaminate under thermal load.

- If your primary focus is System Integration: You require a stable CTE to predict exactly how components will fit together at operating temperatures; non-homogenized data will lead to tolerance errors.

- If your primary focus is Material Processing: You should monitor the hysteresis loop; a minimized loop confirms your heat treatment cycle successfully stabilized the alloy's microstructure.

Accurate material characterization begins with a uniform, stress-free sample; without homogenization, you are measuring defects, not the alloy.

Summary Table:

| Factor Affected | As-Cast Material Status | Post-Homogenization Benefit |

|---|---|---|

| Chemical Composition | Dendritic segregation / Uneven | Uniform elemental diffusion |

| Internal Stress | High residual cooling stresses | Stress-free, stable structure |

| Carbide Morphology | Irregular precipitates | Controlled morphological transformation |

| Data Reliability | Hysteresis and fluctuating CTE | Stable CTE & minimized hysteresis loop |

| Structural Integrity | Risk of embrittlement | Protected (via vacuum environment) |

Maximize Your Material Testing Precision with KINTEK

Don't let casting defects compromise your research. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for critical homogenization processes. Whether you need to eliminate dendritic segregation or achieve a stable CTE, our customizable lab furnaces provide the precise temperature and vacuum control required for advanced refractory alloys.

Ready to upgrade your lab's thermal processing? Contact us today to discuss your unique needs!

References

- High-Temperature Oxidation and Thermal Expansion Behavior of NbTi–X (X = 5Co, 10Cr, 10Ni, 10CoCrNi) Refractory Medium Entropy Alloys. DOI: 10.1007/s11661-025-07911-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of a sealed heating reactor in MSNs synthesis? Master Precision Pore Uniformity

- What are the benefits of ESR for carbonitride distribution in H13 steel? Enhance Your Material's Isotropic Properties

- Why is argon gas preferred over other inert gases? Discover Its Optimal Balance for Industrial Use

- Why is Boron Nitride (BN) powder used as a diluent? Enhance Accuracy in Iron Oxidation Kinetics

- What is the necessity of the subsequent pyrolysis step in ZnS-CFC preparation? Unlocking High-Performance Carbonization

- Why is it necessary to thoroughly dry biomass raw materials before starting a pyrolysis experiment? Improve Yields

- Why is a laboratory oven required for drying samples at 80°C for MoO3/Ti-Felt? Ensure Electrode Structural Integrity

- How does a vacuum drying oven contribute to biodiesel moisture control? Ensure Fuel Quality & Stability