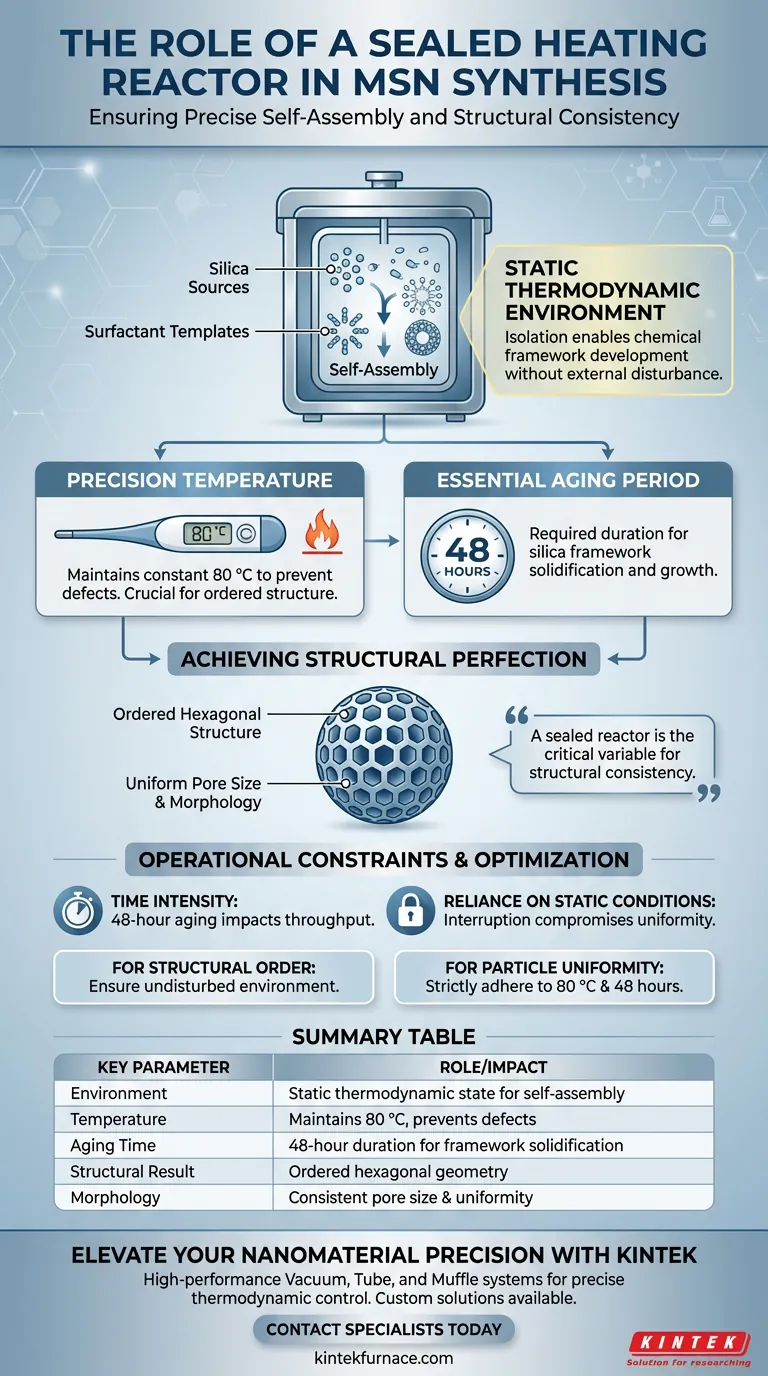

The role of a sealed heating reactor in the synthesis of mesoporous silica nanoparticles (MSNs) is to provide a strictly controlled, static thermodynamic environment. This isolation enables the precise self-assembly of silica sources around surfactant templates, ensuring the chemical framework develops without external disturbance.

A sealed reactor is the critical variable for structural consistency; by maintaining a constant temperature of 80 °C for 48 hours, it guarantees the formation of an ordered hexagonal structure with uniform pore size and morphology.

Establishing the Thermodynamic Environment

Creating Static Conditions

The synthesis of MSNs is a delicate process that requires stability. A sealed heating reactor eliminates external fluctuations, providing a static thermodynamic environment.

Facilitating Self-Assembly

This controlled environment is essential for the chemical mechanism at play. It facilitates the self-assembly of silica sources around surfactant templates, which serves as the blueprint for the nanoparticle's structure.

The Role of Aging and Temperature

Precision Temperature Maintenance

Temperature fluctuations can lead to defects in the material. The reactor maintains a precise, constant temperature of 80 °C.

Essential Aging Period

Time is as critical as temperature. The reactor preserves these conditions for a 48-hour aging period, which is necessary for the silica framework to grow adequately and solidify its structure.

Achieving Structural Perfection

Ordered Hexagonal Structure

The ultimate goal of using this specific apparatus is geometric order. The stability provided by the reactor results in the formation of a distinct ordered hexagonal structure.

Uniformity in Pores and Morphology

Quality in nanoparticle synthesis is defined by consistency. The controlled environment ensures that the resulting particles exhibit uniform pore size and consistent morphology across the entire batch.

Understanding the Operational Constraints

Time Intensity

The requirement for a 48-hour aging period is a significant constraint. This extended duration means the synthesis process is time-intensive, which impacts production throughput.

Reliance on Static Conditions

The process relies heavily on the environment remaining static. Any interruption to the seal or failure to maintain the 80 °C set point during the two-day period can compromise the uniformity of the final product.

Optimizing for Consistency

To ensure the successful synthesis of high-quality MSNs, you must respect the strict parameters of the reaction environment.

- If your primary focus is structural order: Ensure the reactor remains completely undisturbed to allow the hexagonal structure to form correctly.

- If your primary focus is particle uniformity: Strictly adhere to the 80 °C temperature and the full 48-hour duration to guarantee consistent pore size and morphology.

Control the environment precisely, and the self-assembly process will yield a predictable, high-quality material.

Summary Table:

| Key Parameter | Role/Impact in MSN Synthesis |

|---|---|

| Environment | Provides a static thermodynamic state for silica self-assembly |

| Temperature | Maintains a precise 80 °C to prevent structural defects |

| Aging Time | 48-hour duration required for solidifying the silica framework |

| Structural Result | Formation of a distinct, ordered hexagonal geometry |

| Morphology | Guarantees consistent pore size and particle uniformity |

Elevate Your Nanomaterial Precision with KINTEK

Achieving the perfect ordered hexagonal structure in MSNs requires unwavering environmental control. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Vacuum, Tube, and Muffle systems designed to maintain precise thermodynamic conditions for extended aging periods. Whether you need a standard setup or a customizable lab furnace tailored to your unique synthesis protocols, our equipment ensures the stability your research demands.

Ready to optimize your nanoparticle yields? Contact our specialists today to find the ideal high-temperature solution for your laboratory.

Visual Guide

References

- Mesoporous Silica-Loaded PCL-CHT Hybrid Membranes for Skin Regeneration. DOI: 10.1021/acsami.5c09164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What role does an infrared image furnace play in the Floating Zone Method? Mastering Nb-doped beta-Ga2O3 Crystal Growth

- Why is it necessary to use an annealing furnace at 350°C for three hours? Ensuring Glass Stability and Clarity

- Why is substrate preheating typically employed during the LPBF process? Minimize Stress & Prevent Cracks in 3D Printing

- Why is a laboratory drying oven used for cottonseed oil extraction? Achieve Maximum Yield and Accuracy

- What is the primary function of multi-stage oxidation ovens? Secure High-Strength Carbon Fiber Stabilization

- What are the advantages of a benchtop industrial oven in terms of usability? Enhance Lab Efficiency with Compact Design

- What is the function of a laboratory drying oven in thin film solvent removal? Ensure Defect-Free Solidification

- Why is a pre-melting process required in phase equilibrium studies? Reset Your Sample for Precise Results