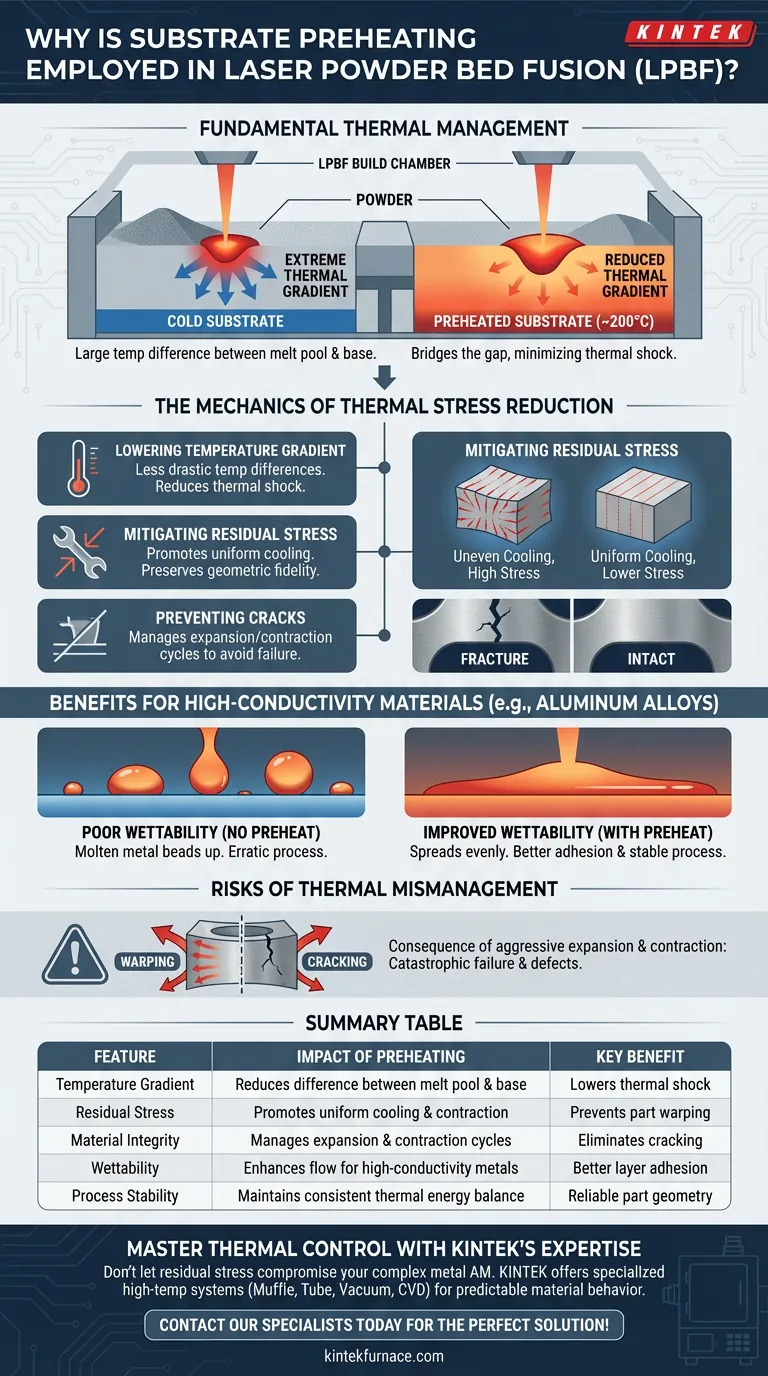

Substrate preheating is a fundamental thermal management strategy in Laser Powder Bed Fusion (LPBF) used to stabilize the printing environment. By raising the temperature of the build plate—often to around 200 degrees Celsius—operators can significantly minimize the drastic temperature differences that occur when the laser melts the powder. This process is essential for preventing structural failures and ensuring the material behaves predictably during deposition.

The primary function of substrate preheating is to reduce the temperature gradient between the molten pool and the solid base. This reduction lowers residual stress, prevents cracking caused by thermal expansion, and improves the flow of specific materials like aluminum alloys.

The Mechanics of Thermal Stress Reduction

Lowering the Temperature Gradient

During LPBF, the laser introduces intense localized heat. If the substrate is cold, the temperature difference (gradient) between the melt pool and the base is extreme.

Preheating the substrate bridges this gap. By starting at an elevated temperature, the thermal shock experienced by the material is significantly reduced.

Mitigating Residual Stress

When metal heats and cools rapidly, it expands and contracts. In LPBF, uneven cooling leads to internal forces known as residual stress.

Preheating ensures the part cools more uniformly. This keeps internal stresses lower, preserving the geometric fidelity of the component.

Preventing Cracks

High residual stress often exceeds the strength of the material, leading to fractures.

By managing the thermal expansion and contraction cycles through preheating, the tendency for the part to crack during formation is effectively mitigated.

Benefits for High-Conductivity Materials

Improving Wettability

For materials with high thermal conductivity, such as aluminum alloys, how the molten metal interacts with the underlying layer is critical.

Preheating improves wettability, allowing the molten pool to spread more evenly across the surface rather than beading up.

Stabilizing the Process

Aluminum dissipates heat very quickly, which can make the welding process erratic.

Adding heat to the substrate helps maintain a stable thermal energy balance. This ensures the molding process remains consistent layer after layer.

The Risks of Thermal Mismanagement

The Consequence of Expansion and Contraction

The primary "trade-off" in LPBF is the battle against physics. If preheating is ignored or insufficient, the rapid thermal cycles force the material to expand and contract aggressively.

The Threat to Structural Integrity

This physical movement translates directly into defects. Without adequate heat in the substrate, the likelihood of catastrophic failure—specifically cracking and warping—increases drastically.

Applying Thermal Control to Your Build

Understanding why you are heating the plate helps you prioritize process parameters based on your material and geometry.

- If your primary focus is Defect Prevention: Ensure the preheat temperature is sufficient to lower the thermal gradient, thereby reducing the risk of cracking from residual stress.

- If your primary focus is Aluminum Alloys: Utilize preheating specifically to enhance wettability and maintain a stable molten pool against high thermal conductivity.

mastering substrate temperature is not merely a setup step; it is a critical control lever for ensuring the viability and quality of the final metal part.

Summary Table:

| Feature | Impact of Preheating | Key Benefit |

|---|---|---|

| Temperature Gradient | Reduces difference between melt pool and base | Lowers thermal shock |

| Residual Stress | Promotes uniform cooling and contraction | Prevents part warping |

| Material Integrity | Manages expansion and contraction cycles | Eliminates cracking |

| Wettability | Enhances flow for high-conductivity metals | Better layer adhesion |

| Process Stability | Maintains consistent thermal energy balance | Reliable part geometry |

Master Thermal Control with KINTEK’s High-Temp Expertise

Don't let residual stress or cracking compromise your complex metal additive manufacturing. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique lab and production needs. Whether you are optimizing LPBF substrate temperatures or requiring precision high-temp furnaces, our equipment ensures predictable material behavior and superior structural integrity.

Ready to elevate your material processing? Contact our technical specialists today to find the perfect solution for your thermal management challenges!

Visual Guide

References

- Zhiheng Shu, Yunzhong Liu. Microstructure and Mechanical Properties of a Novel Al-Mg-Sc-Ti Alloy Fabricated by Laser Powder Bed Fusion. DOI: 10.3390/ma17030686

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the applications of heat treatment furnaces in the aerospace industry? Enhance Component Performance for Extreme Conditions

- How does a high-precision temperature control system influence the nanoparticle size? Master Catalyst Activation

- What are the technological advantages of using a Rapid Thermal Annealing (RTA) system? Precision for Semiconductors

- What are the advantages of SLRP compared to traditional high-temperature furnaces? Revolutionizing UHTC Coatings

- Why is annealing in a heat treatment furnace performed on graphite flake/copper composite samples before performance testing? Ensure Data Integrity for Precision Thermal Expansion Measurements

- What are the technical advantages of using a six-zone resistance heating furnace in VGF-VB? Unlock Precision Growth

- What is the objective of performing an annealing treatment? Enhance Plasticity and Stress Relief for Al-Composites

- Why is thermal annealing of native substrates required for β-Ga2O3? Optimize Your Epitaxial Growth Foundation