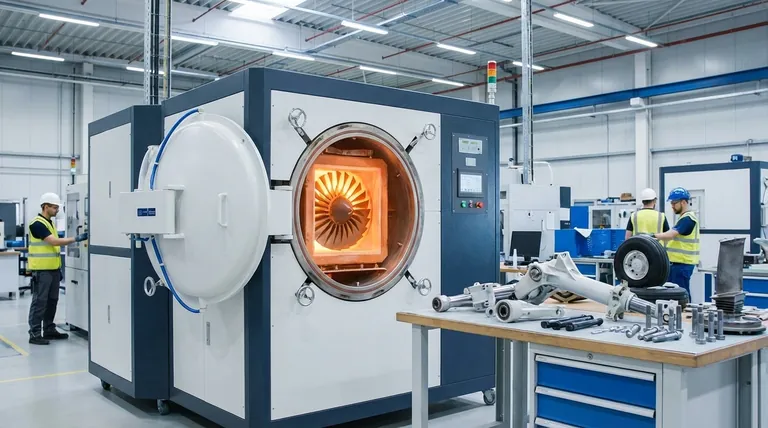

In the aerospace industry, heat treatment furnaces are essential for transforming high-performance alloys into components capable of withstanding extreme operational conditions. These furnaces are used to execute precise thermal processes on parts like engine turbine blades, landing gear, and structural fasteners, fundamentally altering their metallurgical properties to achieve the required levels of strength, fatigue resistance, and durability for safe flight.

The core purpose of heat treatment in aerospace is not merely to harden metal. It is a highly controlled engineering process designed to unlock the specific, often unique, performance characteristics of advanced alloys, ensuring components function reliably under stresses where failure is not an option.

The Core Challenge: Materials for Extreme Environments

The operational environment of an aircraft is unforgiving. Components face incredible temperature gradients, from cryogenic temperatures at high altitudes to over 1,000°C inside a jet engine. They must also endure immense physical stress and cyclical loading during takeoff, flight, and landing.

Standard metals cannot meet these demands. The aerospace industry relies on specialized superalloys (nickel-based, cobalt-based) and titanium alloys, whose superior properties are only activated through precise heat treatment.

Key Processes and Their Aerospace Applications

Different components require different properties, which are achieved through distinct heat treatment processes. Each process involves a carefully controlled cycle of heating, holding at a specific temperature, and cooling.

Solution Annealing and Precipitation Hardening

This two-step process is the key to unlocking the potential of high-performance superalloys used in the hottest sections of a jet engine.

First, solution annealing dissolves the alloy's strengthening elements evenly into the base metal at a very high temperature. The material is then rapidly cooled, or "quenched," to lock this structure in place.

Next, precipitation hardening (or aging) involves reheating the component to a lower temperature. This causes microscopic particles to precipitate out of the metal's crystal structure, acting like reinforced pins that dramatically increase strength and creep resistance at high temperatures. This is critical for turbine blades and discs that spin at thousands of RPM in extreme heat.

Hardening and Tempering

This classic process is used to create components with exceptional strength and toughness. It is vital for structural parts that must bear immense loads without fracturing.

The part is first heated to a high temperature and then rapidly quenched in a medium like oil or water, making it extremely hard but also brittle. The subsequent tempering process involves reheating it to a lower temperature to reduce that brittleness, resulting in a final product with an optimal balance of hardness and ductility. This is the primary treatment for steel alloy landing gear, which must absorb massive impacts on every landing.

Annealing

Annealing is a process of heating and slow cooling that makes metal softer, more ductile, and easier to work with.

In aerospace, annealing is often used to relieve internal stresses built up during manufacturing processes like forging or machining. This prevents distortion or cracking later in the component's life and prepares the material for subsequent forming operations.

Brazing and Stress Relief

Furnaces are also used for joining complex assemblies. Vacuum brazing uses a filler metal to join parts together inside a vacuum furnace.

This process is ideal for creating leak-proof joints in components like fuel lines or heat exchangers without compromising the integrity of the parent materials. The controlled furnace cycle often incorporates stress relief, ensuring the finished assembly is stable and free from residual stresses.

Understanding the Trade-offs and Risks

While essential, heat treatment is a process with little room for error. The precision of the furnace directly impacts the quality and safety of the final component.

The Peril of Improper Treatment

Even minor deviations in temperature, hold time, or cooling rate can be catastrophic. Overheating can ruin a material's grain structure, while incorrect quenching can lead to brittleness or cracking. The result is a component that may pass initial inspection but fail prematurely in service.

Atmosphere Control is Non-Negotiable

Many aerospace alloys, particularly titanium, are highly reactive to oxygen at high temperatures. Heat treatment must be conducted in a vacuum or an inert gas atmosphere (like argon) to prevent oxidation, which can create a brittle surface layer and compromise fatigue life.

The Challenge of Uniformity

Ensuring every part of a large or complex component reaches the exact same temperature for the exact same amount of time is a significant engineering challenge. Modern aerospace furnaces use advanced controls and multiple heating zones to guarantee thermal uniformity, preventing weak spots from forming.

Applying the Right Process for the Mission

The choice of heat treatment is dictated entirely by the component's function and the material it is made from.

- If your primary focus is high-temperature performance (e.g., turbine blades): Solution annealing and precipitation hardening of nickel-based superalloys are the critical processes.

- If your primary focus is structural strength and impact resistance (e.g., landing gear): Hardening and tempering of high-strength steel alloys are the standard.

- If your primary focus is formability and stress relief during manufacturing (e.g., fuselage panels): Annealing is the necessary preparatory or intermediate step.

- If your primary focus is joining complex assemblies (e.g., heat exchangers): Controlled atmosphere or vacuum brazing is the ideal method.

Ultimately, heat treatment is the invisible science that enables modern aircraft to perform safely and reliably under the most demanding conditions imaginable.

Summary Table:

| Component | Heat Treatment Process | Key Benefits |

|---|---|---|

| Turbine Blades | Solution Annealing & Precipitation Hardening | High-temperature strength, creep resistance |

| Landing Gear | Hardening & Tempering | Strength, toughness, impact resistance |

| Structural Fasteners | Various (e.g., Annealing) | Stress relief, improved ductility |

| Heat Exchangers | Vacuum Brazing | Leak-proof joints, stress relief |

Elevate Your Aerospace Manufacturing with KINTEK's Advanced Furnace Solutions

At KINTEK, we understand the critical role of precise heat treatment in aerospace. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Whether you're working on turbine blades, landing gear, or complex assemblies, our furnaces ensure uniform heating, precise temperature control, and reliable performance under extreme conditions. Contact us today to discuss how we can enhance your component durability and safety—Get in touch now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability