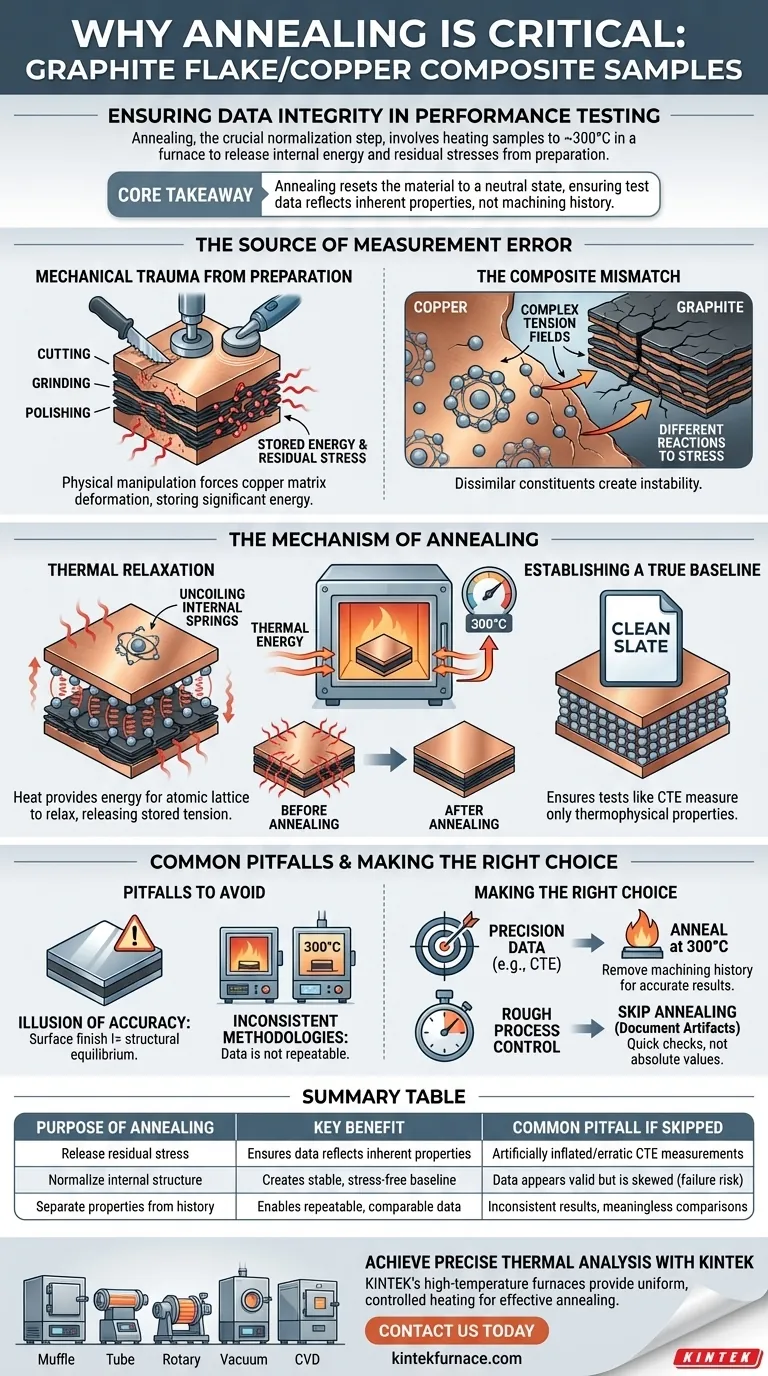

Annealing is the critical normalization step required to ensure data integrity in composite materials. For graphite flake/copper composites, this process involves heating the sample to approximately 300°C in a heat treatment furnace to release internal energy. This eliminates the residual stresses caused by cutting and polishing, preventing them from skewing the results of sensitive performance tests like thermal expansion measurements.

Core Takeaway: The mechanical preparation of a sample creates invisible internal tension. Annealing resets the material to a neutral state, ensuring that subsequent test data reflects the material's inherent properties rather than the history of how it was machined.

The Source of Measurement Error

Mechanical Trauma from Preparation

Preparing a composite sample for testing is a violent process at the microscopic level. Techniques like cutting, grinding, and polishing apply significant mechanical force to the material.

This physical manipulation forces the copper matrix to deform plastically. While the sample may look smooth to the naked eye, the atomic structure holds significant stored energy in the form of residual stress.

The Composite Mismatch

Graphite flake/copper composites face a unique challenge due to the dissimilarity of their constituents. Copper is ductile and metallic, while graphite is brittle and layered.

When machined, these materials react differently to physical stress. This creates complex tension fields at the interface where the copper meets the graphite flakes, making the material unstable for precision testing.

The Mechanism of Annealing

Thermal Relaxation

Annealing addresses this instability by introducing controlled thermal energy. By heating the sample to 300°C in a muffle or atmosphere furnace, you provide the energy necessary for the atomic lattice to relax.

This process allows the material to release the tension stored during machining. It effectively "uncoils" the internal springs created by mechanical deformation without altering the material's composition.

Establishing a True Baseline

The ultimate goal of this thermal treatment is to create a "clean slate." Precision tests, particularly those measuring the coefficient of thermal expansion (CTE), rely on a stable starting point.

If a sample is not annealed, the initial heating phase of the test will measure both the material's natural expansion and the release of manufacturing stress. Annealing separates these variables, ensuring the test measures only the thermophysical properties.

Common Pitfalls to Avoid

The Illusion of Accuracy

A common mistake is assuming that a highly polished sample is ready for testing. Surface finish does not equate to structural equilibrium.

Skipping the annealing step often results in data that looks valid but is actually skewed. This is particularly dangerous in high-precision applications where even minor deviations in thermal expansion data can lead to component failure.

Inconsistent Methodologies

Data is only valuable if it is repeatable. If samples are annealed at different temperatures or skipped entirely, comparisons between batches become meaningless.

Standardizing the annealing temperature (typically 300°C for this specific composite) is just as important as the testing method itself. It ensures that every sample starts from the same stress-free state.

Making the Right Choice for Your Goal

To obtain reliable data, you must align your preparation steps with your measurement objectives.

- If your primary focus is Precision Data (e.g., CTE): You must anneal the sample at 300°C to remove machining history; otherwise, your thermal expansion coefficients will be artificially inflated or erratic.

- If your primary focus is Rough Process Control: You might skip annealing for quick checks, but you must document that the results include residual stress artifacts and are not absolute values.

Annealing is not merely a preparation step; it is the prerequisite for scientific truth in material characterization.

Summary Table:

| Purpose of Annealing | Key Benefit | Common Pitfall if Skipped |

|---|---|---|

| Release residual stress from cutting/polishing | Ensures test data reflects inherent material properties | Artificially inflated or erratic CTE measurements |

| Normalize the composite's internal structure | Creates a stable, stress-free baseline for testing | Data appears valid but is skewed, risking component failure |

| Separate material properties from machining history | Enables repeatable, comparable, and precise data | Inconsistent results make batch comparisons meaningless |

Achieve precise and reliable thermal analysis data with the right laboratory furnace.

The integrity of your material testing starts with precise sample preparation. KINTEK's high-temperature furnaces, including Muffle and Tube furnaces, provide the uniform, controlled heating essential for effective annealing processes.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique lab needs. Ensure your graphite/copper composite samples are perfectly prepared for accurate CTE and performance testing.

Contact us today to discuss how our furnaces can enhance your lab's capabilities and data integrity. Get in Touch

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is a temperature-controlled heating system required for firing silver electrodes? Ensure Precision Ohmic Contacts

- What factors influence the time and temperature of the annealing process? Optimize Your Heat Treatment for Better Results

- Why is reaching a specific temperature threshold critical during the peat carbonization process? Unlock Pure Metallurgy

- Why is high-temperature drying of NaCl particles necessary? Prevent Aluminum Foam Defects and Ensure Integrity

- What are the primary functions of high-purity nitrogen flow in carbon pyrolysis? Optimize Purity and Pore Structure

- What is the function of a solvothermal reactor? Optimize Carbon Polymer Dots (CPDs) Synthesis with Precision Pressure

- What is a horizontal furnace? A space-saving heating solution for attics and crawl spaces

- What is the function of a pure graphite sheet within a microwave hybrid heating setup? Ensure Pure Ni-BN Cladding