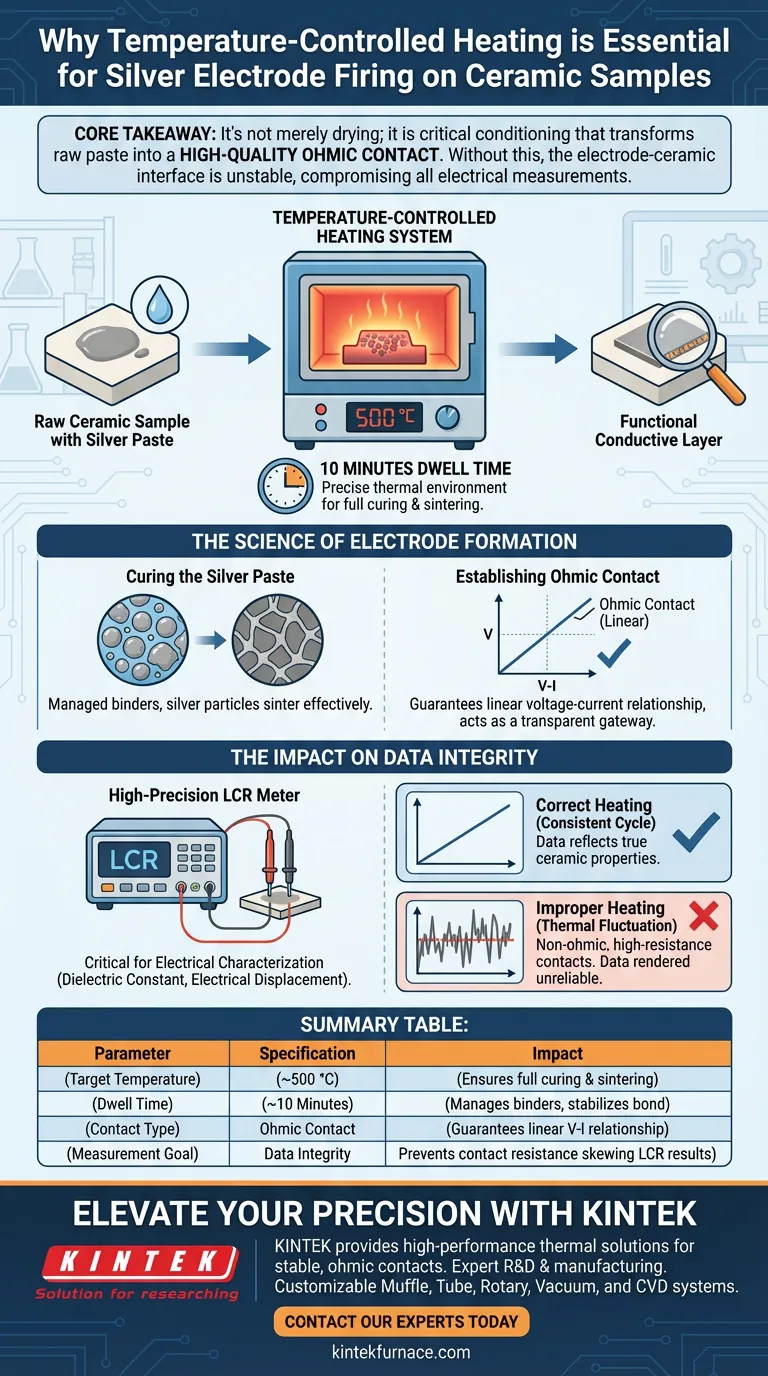

A temperature-controlled heating system is essential because it provides the precise thermal environment required to fire silver electrodes at approximately 500 °C for a specific duration, typically 10 minutes. This controlled heating process is the only way to fully cure the silver paste, ensuring it bonds correctly to the ceramic substrate to form a functional conductive layer.

Core Takeaway The application of heat is not merely for drying; it is a critical conditioning step that transforms raw silver paste into a high-quality ohmic contact. Without this specific thermal treatment, the interface between the electrode and the ceramic will be unstable, compromising the accuracy of all subsequent electrical measurements.

The Science of Electrode Formation

Curing the Silver Paste

Silver paste does not function as a reliable conductor immediately upon application. It requires a specific thermal profile to transition from a wet paste into a solid, conductive electrode.

A temperature-controlled system ensures the sample reaches the target temperature of 500 °C. Sustaining this temperature for a set time (e.g., 10 minutes) ensures the binders in the paste are managed and the silver particles sinter effectively.

Establishing Ohmic Contact

The primary goal of the firing process is to create an ohmic contact with the ceramic surface.

An ohmic contact ensures that the electrical connection follows Ohm's law, providing a linear relationship between voltage and current. This type of low-resistance junction is necessary to ensure that the electrode acts as a transparent gateway for electrical signals, rather than a barrier.

The Impact on Data Integrity

Critical for Electrical Characterization

Once the electrodes are fired, the ceramic samples undergo rigorous testing using high-precision LCR meters or ferroelectric test systems.

These instruments measure delicate properties such as dielectric constant and electrical displacement. If the electrode firing process is inconsistent, the data collected by these sophisticated instruments will be flawed.

Ensuring Dependability

A temperature-controlled system removes variables from the fabrication process. By guaranteeing a consistent firing cycle, you ensure that the data collected reflects the true properties of the ceramic material, rather than artifacts caused by poor electrode adhesion.

Risks of Improper Heating

The Danger of Thermal Fluctuation

If the heating system lacks precise control, the silver paste may fail to cure completely or may cure unevenly across the sample surface.

Compromised Measurement Accuracy

Inadequate firing leads to non-ohmic or high-resistance contacts. In this scenario, your test equipment measures the resistance of the poor contact rather than the properties of the ceramic, rendering your dielectric and displacement data unreliable.

Making the Right Choice for Your Goal

To ensure your experimental setup yields publication-quality data, consider the following recommendations:

- If your primary focus is fabrication consistency: Ensure your heating system can maintain a steady 500 °C for at least 10 minutes to guarantee full paste curing.

- If your primary focus is data accuracy: Verify that your firing process yields a verifiable ohmic contact before proceeding to high-precision LCR testing.

Precision in the firing process is the invisible foundation of accurate material characterization.

Summary Table:

| Parameter | Specification | Impact on Outcome |

|---|---|---|

| Target Temperature | Approximately 500 °C | Ensures full curing and sintering of silver paste |

| Dwell Time | Typically 10 Minutes | Manages binders and stabilizes electrode bond |

| Contact Type | Ohmic Contact | Guarantees linear voltage-current relationship |

| Measurement Goal | Data Integrity | Prevents contact resistance from skewing LCR results |

Elevate Your Material Characterization Precision

Inconsistent electrode firing can ruin hours of research. KINTEK provides the high-performance thermal solutions you need to guarantee stable, ohmic contacts every time. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for your unique lab requirements.

Don't let poor heating compromise your data integrity—partner with KINTEK for reliable, high-temperature lab furnaces.

Visual Guide

References

- Novel high-<i>T</i>C piezo-/ferroelectric ceramics based on a medium-entropy morphotropic phase boundary design strategy. DOI: 10.1063/5.0244768

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a laboratory vacuum drying oven in BAFPAE processing? Maintain Precursor Purity and Stability

- Why is an electric heating furnace integrated with a capsule-piercing reactor? Ensure Precise Fluid Analysis

- What is the function of a solvothermal reactor? Optimize Carbon Polymer Dots (CPDs) Synthesis with Precision Pressure

- What are the advantages and disadvantages of microwave drying for iron ore briquettes? Expert Process Insights

- What is the role of an industrial oven in the drying stage of Rosa roxburghii biochar? Unlock Structural Integrity

- What role does a reactive atmosphere like nitrogen play in PFS? Enhance Titanium Dioxide Surface Treatment

- What are the advantages of HTL reactors for algae? Optimize Biomass Conversion Without Pre-Drying

- Why is stepped temperature control on a laboratory hotplate necessary for drying sensor active layers? Boost Precision