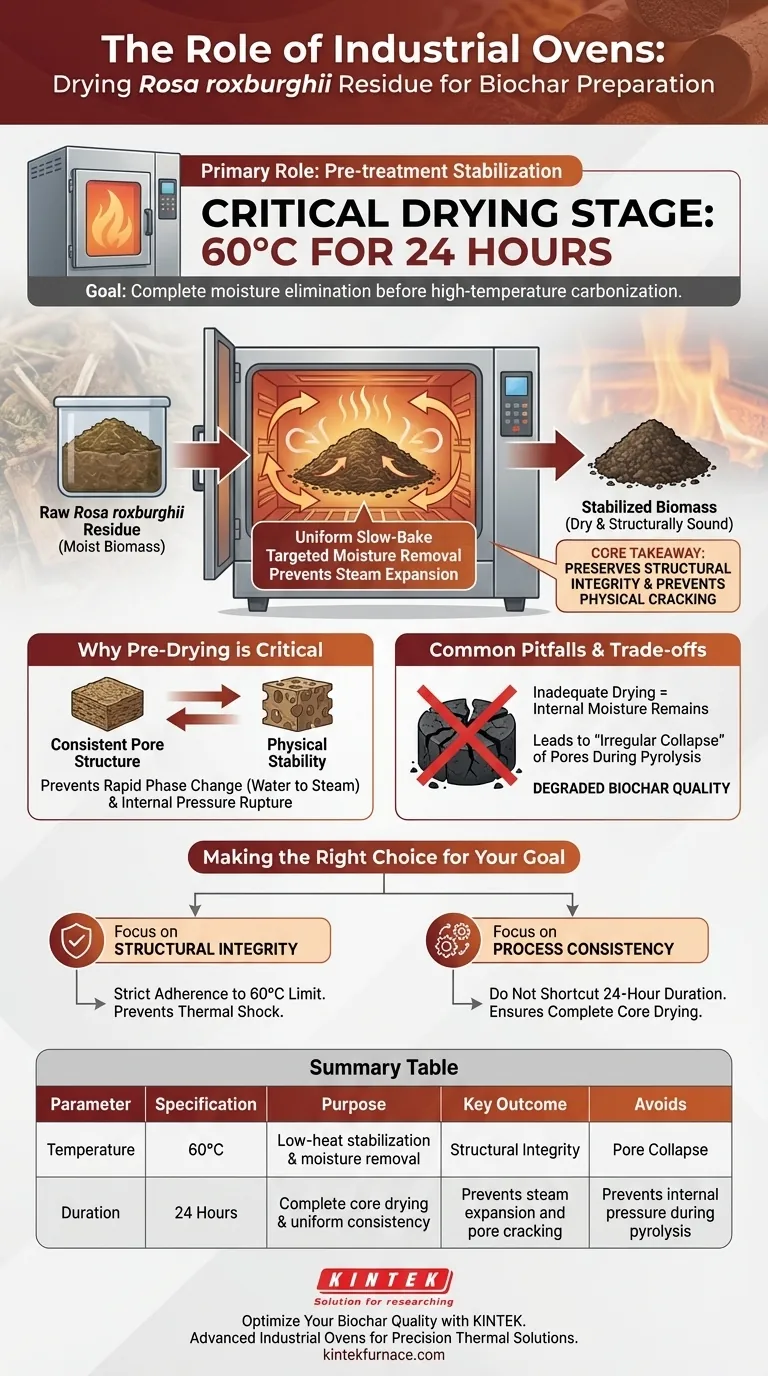

The primary role of the industrial oven in this process is to serve as a critical pre-treatment stabilization step. Specifically, the oven is used to dry the Rosa roxburghii residue at 60°C for 24 hours to completely eliminate moisture from the biomass before it enters the high-temperature carbonization stage.

Core Takeaway The drying stage is not merely about removing water; it is about preserving the material's structural integrity. By eliminating moisture slowly at low temperatures, you prevent the rapid steam expansion that causes physical cracking and pore collapse during the intense heat of pyrolysis.

The Mechanics of the Drying Phase

Specific Process Parameters

For Rosa roxburghii residue specifically, precision is key. The protocol requires maintaining a steady temperature of 60°C for a continuous duration of 24 hours.

Targeted Moisture Removal

This extended duration ensures the complete removal of free moisture held within the biomass. Unlike flash-drying methods, this slow-bake approach ensures the material is dried uniformly from the surface to the internal core.

Why Pre-Drying is Critical for Quality

Preventing Structural Cracking

If moisture remains in the residue during the subsequent high-temperature carbonization, it will vaporize instantly. This rapid phase change from water to steam creates immense internal pressure.

This pressure causes the raw material to rupture or crack. The industrial oven eliminates this risk by removing the water before the heat becomes intense enough to cause explosive evaporation.

Ensuring Physical Stability

The physical properties of the final biochar depend heavily on the integrity of the raw material. By preventing cracking early in the process, the oven ensures the material maintains a stable physical structure throughout the conversion process.

Common Pitfalls and Trade-offs

The Risk of Inadequate Drying

Rushing this stage is a common error. If the drying time is shortened or the temperature is too low to fully penetrate the material, internal moisture will remain.

This residual moisture leads to "irregular collapse" of the pore structure during pyrolysis. This degrades the quality of the biochar, making it less effective for applications requiring high surface area or porosity.

Temperature Sensitivity

While other materials like oil palm shells or coconut husks may require higher drying temperatures (100°C–120°C), Rosa roxburghii utilizes a gentler 60°C. Deviating from this specific temperature could alter the biomass chemistry prematurely or fail to dry it efficiently.

Making the Right Choice for Your Goal

The industrial oven acts as the gatekeeper between raw biomass and high-quality biochar.

- If your primary focus is Structural Integrity: Ensure strict adherence to the 60°C limit, as this gentle heat prevents thermal shock before the material is ready.

- If your primary focus is Process Consistency: Do not shortcut the 24-hour duration, as consistency in the final product relies on the absolute removal of internal moisture pockets.

Success in biochar production is determined not just by how you burn the material, but by how well you prepare it.

Summary Table:

| Parameter | Specification | Purpose |

|---|---|---|

| Temperature | 60°C | Low-heat stabilization & moisture removal |

| Duration | 24 Hours | Complete core drying & uniform consistency |

| Key Outcome | Structural Integrity | Prevents steam expansion and pore cracking |

| Avoids | Pore Collapse | Prevents internal pressure during pyrolysis |

Optimize Your Biochar Quality with KINTEK

Maximize the structural integrity and surface area of your biochar with precision thermal solutions from KINTEK. Whether you are processing Rosa roxburghii or complex biomass materials, our advanced industrial ovens and high-temperature systems provide the exact thermal control needed to prevent pore collapse and ensure consistent results.

Why choose KINTEK?

- Expert R&D & Manufacturing: Our systems are built for research precision and industrial reliability.

- Versatile Solutions: From Muffle and Tube Furnaces to Vacuum and CVD systems, we cover every stage of the carbonization process.

- Tailored to Your Needs: All systems are fully customizable for your specific biomass requirements.

Ready to elevate your lab's efficiency and product quality? Contact us today to find the perfect furnace for your application!

Visual Guide

References

- Yong Dai, Ruyi Zheng. Adsorption and removal of pentavalent antimony from water by biochar prepared from modified rosa roxburghii residue. DOI: 10.3389/fenvs.2024.1540638

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What critical environment does a high-temp furnace provide for H13 steel? Mastering Microstructural Homogenization

- How do thermal stripping tools and heating equipment facilitate solar panel recycling? High-Value Glass Recovery Guide

- What role does thermal processing with precise temperature control and tensile stress play in PVDF fiber stabilization?

- How does a laboratory oven contribute to the hydrothermal treatment of graphene aerogels? Master High-Strength Synthesis

- What physical environment does a laboratory oven provide for perovskite annealing? Master Thermal Precision & Strain Control

- How does the speed-controlled motor in a high-pressure autoclave influence the yield of glucose from starch?

- Why is a vacuum drying oven required for the pretreatment of modified zeolite? Preserve Pore Integrity for CO2 Capture

- Why is HR-TEM used after high-temperature heat treatment? Visualize structural evolution and material integrity.