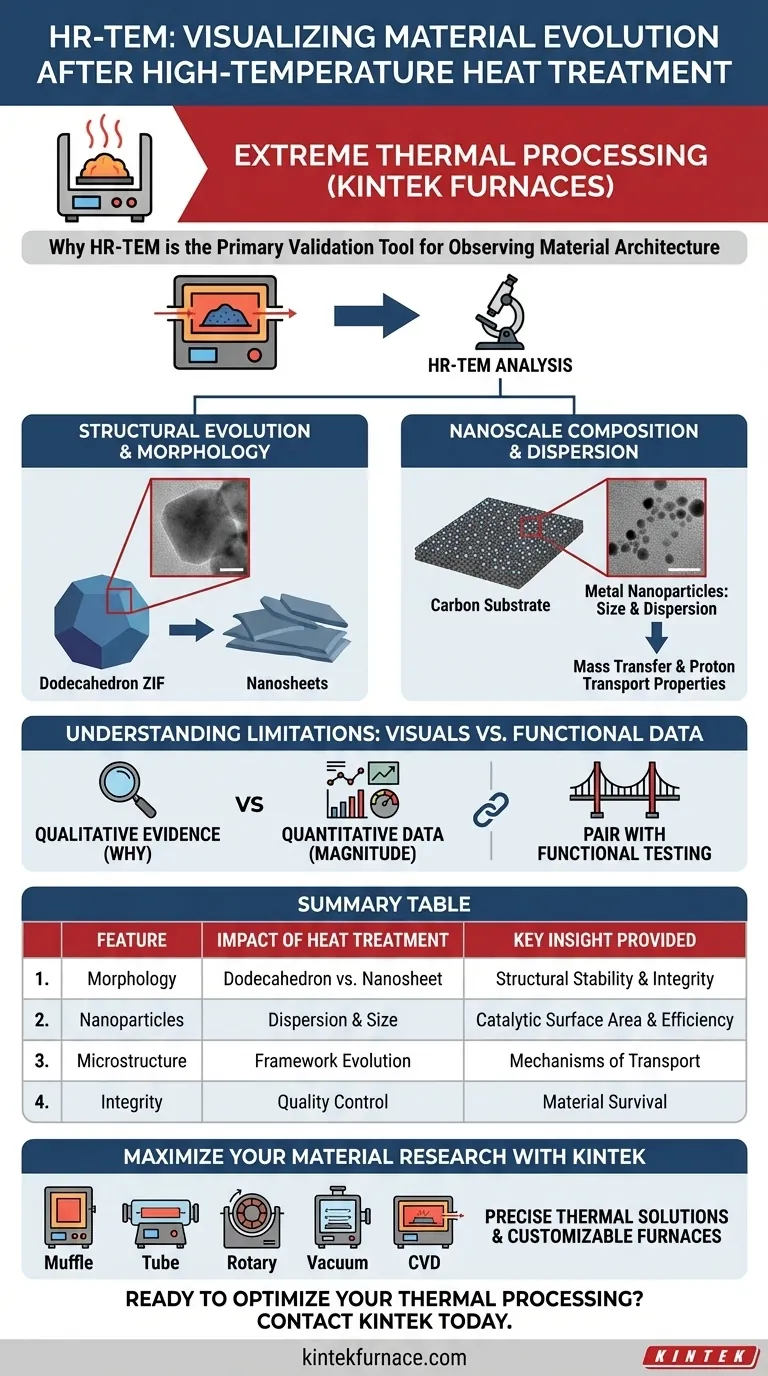

High-resolution transmission electron microscopy (HR-TEM) serves as the primary validation tool for visualizing how extreme thermal processing alters the fundamental architecture of a material. It allows researchers to directly observe "morphology evolution," confirming whether complex structures retain their original geometric shape or collapse into new forms following heat treatment in a high-temperature furnace.

Core Takeaway HR-TEM bridges the gap between thermal processing and material performance. By providing sub-micron visualization of structural changes—such as the collapse of frameworks or the dispersion of nanoparticles—it reveals the physical mechanisms responsible for shifts in mass transfer and proton transport properties.

Analyzing Structural Evolution

Visualizing Morphology Changes

Heat treatment significantly impacts the physical form of materials. HR-TEM is utilized to capture high-fidelity images that demonstrate exactly how the material's morphology evolves under specific thermal conditions.

Verifying Structural Integrity

For advanced materials like Zeolitic Imidazolate Frameworks (ZIFs), this imaging is essential for quality control. It reveals whether the material maintains its intended original structure, such as a dodecahedron, or if the thermal stress has caused it to collapse into nanosheets.

Assessing Material Composition at the Nanoscale

Tracking Metal Nanoparticles

Beyond the overall shape, HR-TEM provides critical data on the material's surface composition. It produces sub-micron images that display the dispersion and size of metal nanoparticles across the carbon substrate.

Linking Structure to Performance

The distribution of these particles is not just a visual detail; it is a performance indicator. By observing these nanoscale features, researchers can deduce how the furnace's heat affected the material's functional capabilities, specifically regarding mass transfer and proton transport properties.

Understanding the Limitations

Visuals vs. Functional Data

While HR-TEM provides exceptional visual evidence of morphology and dispersion, it is primarily a qualitative imaging tool.

It effectively shows why a material's properties might have changed (e.g., structure collapse), but it does not directly measure the magnitude of those property changes (e.g., the exact rate of proton transport). It must be paired with functional testing for a complete analysis.

Making the Right Choice for Your Goal

HR-TEM is the definitive choice when you need to correlate physical structure with thermal history.

- If your primary focus is Structural Stability: Use HR-TEM to verify if your ZIFs retained their dodecahedron geometry or collapsed into nanosheets.

- If your primary focus is Catalytic or Transport Efficiency: Use HR-TEM to assess the uniformity and size of metal nanoparticles dispersed on the carbon substrate.

By leveraging HR-TEM, you move beyond guessing how heat affected your material and gain the visual proof needed to optimize your thermal processing parameters.

Summary Table:

| Feature Observed | Impact of Heat Treatment | Key Insight Provided |

|---|---|---|

| Morphology | Dodecahedron vs. Nanosheet collapse | Structural stability & geometric integrity |

| Nanoparticles | Dispersion & size on carbon substrate | Catalytic surface area & efficiency |

| Microstructure | Framework evolution | Mechanisms of mass & proton transport |

| Integrity | Quality control post-thermal stress | Verification of material survival |

Maximize Your Material Research with KINTEK

Precise heat treatment is the foundation of high-performance materials. At KINTEK, we provide the advanced thermal solutions necessary to achieve the specific morphology and nanoparticle dispersion required for your most demanding applications.

Whether you are synthesizing ZIFs, carbon substrates, or complex catalysts, our expert-engineered Muffle, Tube, Rotary, Vacuum, and CVD systems offer the thermal precision needed to ensure your materials stand up to HR-TEM scrutiny. All our laboratory high-temperature furnaces are fully customizable to meet your unique research specifications.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your custom furnace needs with our R&D experts.

Visual Guide

References

- Yan Yang, Gai Zhang. Enhanced Electrocatalytic Activity for ORR Based on Synergistic Effect of Hierarchical Porosity and Co-Nx Sites in ZIF-Derived Heteroatom-Doped Carbon Materials. DOI: 10.3390/c11030070

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Ultra High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass for KF

People Also Ask

- What are the advantages of Spark Plasma Sintering (SPS) for TiC alloys? Preserve Precision and Microstructure

- What is the primary function of drying bovine horn biomass for PVC biocomposites? Optimize Material Strength

- Why is an industrial electric drying oven required for catalyst support precursors? Secure Pore Integrity

- Why is high-temperature hydrogen reduction used for HI decomposition catalysts? Boost Efficiency and Surface Purity

- Why must T91 steel ingots undergo long-term homogenization? Ensure High-Performance Microstructural Uniformity

- What is the function of a Mass Flow Controller (MFC)? Achieve Precise Ethanol Vapor Delivery for Graphene Synthesis

- What are the process advantages of using solution impregnation for PtS/Ti3C2Tx? Superior In-Situ Growth vs. Mixing

- What is the role of high-vacuum sealing technology? Precision Synthesis of High-Performance Copper Sulfide