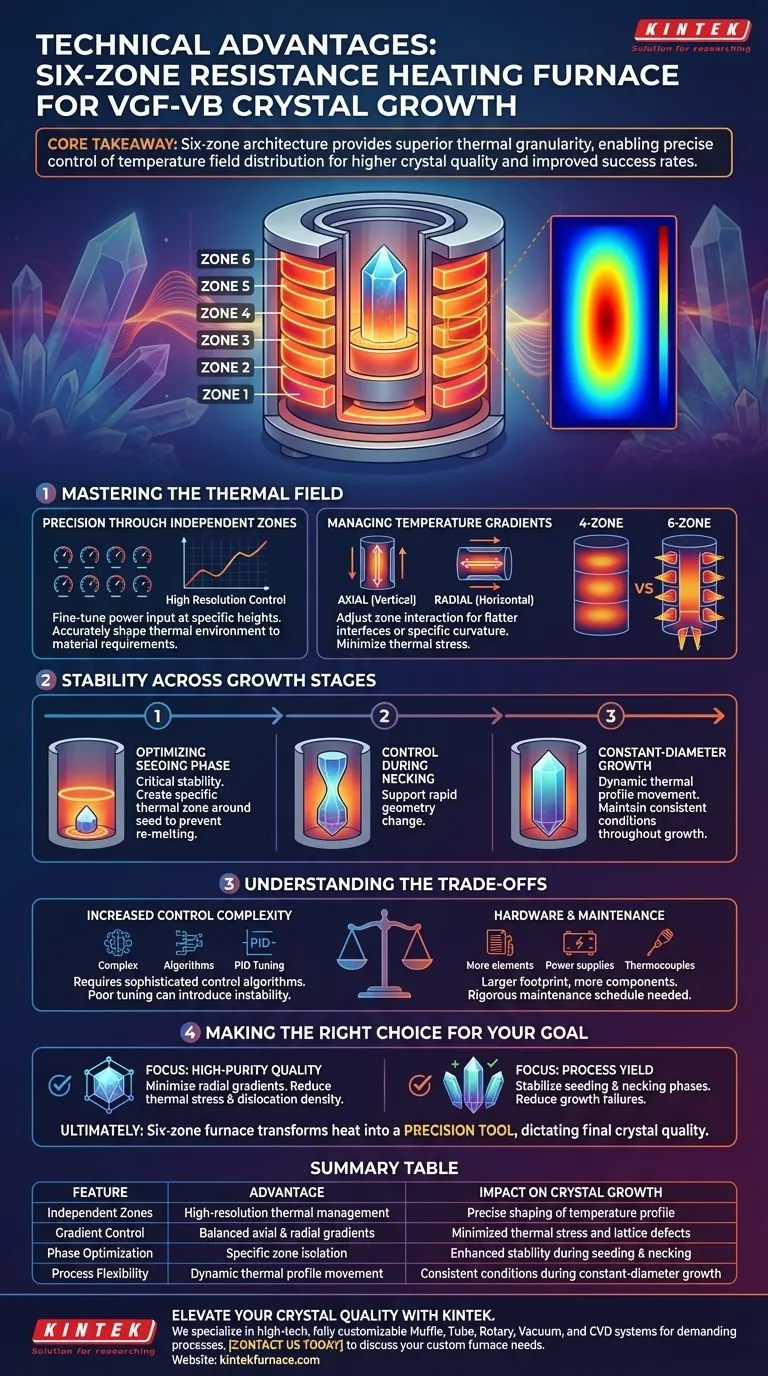

The primary technical advantage of a six-zone resistance heating furnace is its superior granularity in thermal management compared to standard four-zone systems. By utilizing six independently controlled heating zones, this architecture allows for precise manipulation of the temperature field distribution, enabling operators to flexibly manage both axial and radial temperature gradients.

Core Takeaway: Crystal growth demands distinct thermal environments at different stages of development. The six-zone furnace provides the necessary coordinated control to stabilize these environments, directly translating to higher crystal quality and improved success rates in the VGF-VB process.

Mastering the Thermal Field

Precision Through Independent Zones

The defining feature of this furnace architecture is the use of six independent heating zones. Unlike simpler four-zone systems, this configuration allows for a much higher resolution of control over the heating profile.

Through coordinated control, operators can fine-tune the power input at specific heights along the crucible. This ensures that the thermal environment is not just "hot enough," but accurately shaped to the specific requirements of the crystal material.

Managing Temperature Gradients

Successful crystal growth relies heavily on controlling how temperature changes across space. The six-zone system excels at managing axial temperature gradients (vertical changes) and radial temperature gradients (horizontal changes from the center to the wall).

By adjusting the interaction between the six zones, you can create a flatter interface or a specific curvature required for the material. This capability is vital for minimizing thermal stress within the crystal lattice.

Stability Across Growth Stages

Optimizing the Seeding Phase

The seeding stage is the most critical point of the VGF-VB process, requiring extreme stability to prevent re-melting or poly-crystal formation.

The six-zone furnace allows for the creation of a highly specific thermal zone around the seed crystal. This isolation ensures that the seed remains stable while the bulk melt is prepared for solidification.

Control During Necking and Constant-Diameter Growth

As the crystal grows, the thermal requirements shift. During the necking phase, the system must support a rapid change in geometry.

Subsequently, during constant-diameter growth, the goal is uniformity. The multi-zone control allows the thermal profile to "move" dynamically with the growth interface, maintaining consistent conditions throughout the entire length of the crystal.

Understanding the Trade-offs

Increased Control Complexity

While a six-zone system offers superior precision, it introduces a higher level of complexity in process engineering.

Operators must manage more variables, meaning the control algorithms or PID tuning parameters must be more sophisticated than those used in four-zone furnaces. A poorly tuned six-zone system can introduce instability rather than solving it.

Hardware and Maintenance Implications

Adding two additional zones increases the hardware footprint inside the furnace.

This results in more heating elements, power supplies, and thermocouples to maintain and calibrate. The potential for component failure increases statistically, requiring a more rigorous maintenance schedule to ensure all six zones remain synchronized.

Making the Right Choice for Your Goal

To maximize the benefits of the VGF-VB combined process, align your furnace configuration with your specific production targets:

- If your primary focus is high-purity crystal quality: Leverage the six-zone capability to minimize radial gradients, which reduces thermal stress and dislocation density.

- If your primary focus is process yield: Utilize the independent zone control to stabilize the seeding and necking phases, where the majority of growth failures occur.

Ultimately, the six-zone furnace transforms heat from a blunt instrument into a precision tool, giving you the control necessary to dictate the quality of your final crystal.

Summary Table:

| Feature | Advantage | Impact on Crystal Growth |

|---|---|---|

| Independent Zones | High-resolution thermal management | Precise shaping of the temperature profile |

| Gradient Control | Balanced axial & radial gradients | Minimized thermal stress and lattice defects |

| Phase Optimization | Specific zone isolation | Enhanced stability during critical seeding & necking |

| Process Flexibility | Dynamic thermal profile movement | Consistent conditions during constant-diameter growth |

Elevate Your Crystal Quality with KINTEK

Precision thermal management is the difference between a high-yield harvest and a failed melt. At KINTEK, we specialize in providing the high-tech equipment necessary for the most demanding laboratory and industrial processes.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature furnaces—all of which are fully customizable to meet your unique VGF-VB process requirements.

Whether you need to minimize dislocation density or optimize your seeding success rate, our engineering team is ready to design a solution tailored to your goals. Contact us today to discuss your custom furnace needs and see how our expertise can drive your research and production forward.

Visual Guide

References

- Hua Wei, Hui Feng. Growth of 4-Inch InP Single-Crystal Wafer Using the VGF-VB Technique. DOI: 10.1021/acsomega.4c09376

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does starch play in g-C3N4-Bi2S3 and g-C3N4-ZnS synthesis? Enhance Composite Stability and Dispersion

- What is the function of a flash furnace in sludge treatment? Essential Thermal Preparation for Phosphorus Recovery

- Why is a high-purity argon flow control system essential? Ensure Precision in Metallurgy Simulations

- What experimental conditions do physical property measurement systems provide for TaAs2? Explore Cryogenic Transport

- What is the significance of maintaining an inert nitrogen atmosphere during molten salt activation? Ensure Pore Purity

- What is the technical objective of preheating the extrusion cylinder and molds to 460 ℃? Optimize Quality & Flow

- How do thermal stripping tools and heating equipment facilitate solar panel recycling? High-Value Glass Recovery Guide

- What are the benefits of thermal cycling furnaces? Boost Speed, Efficiency, and Durability