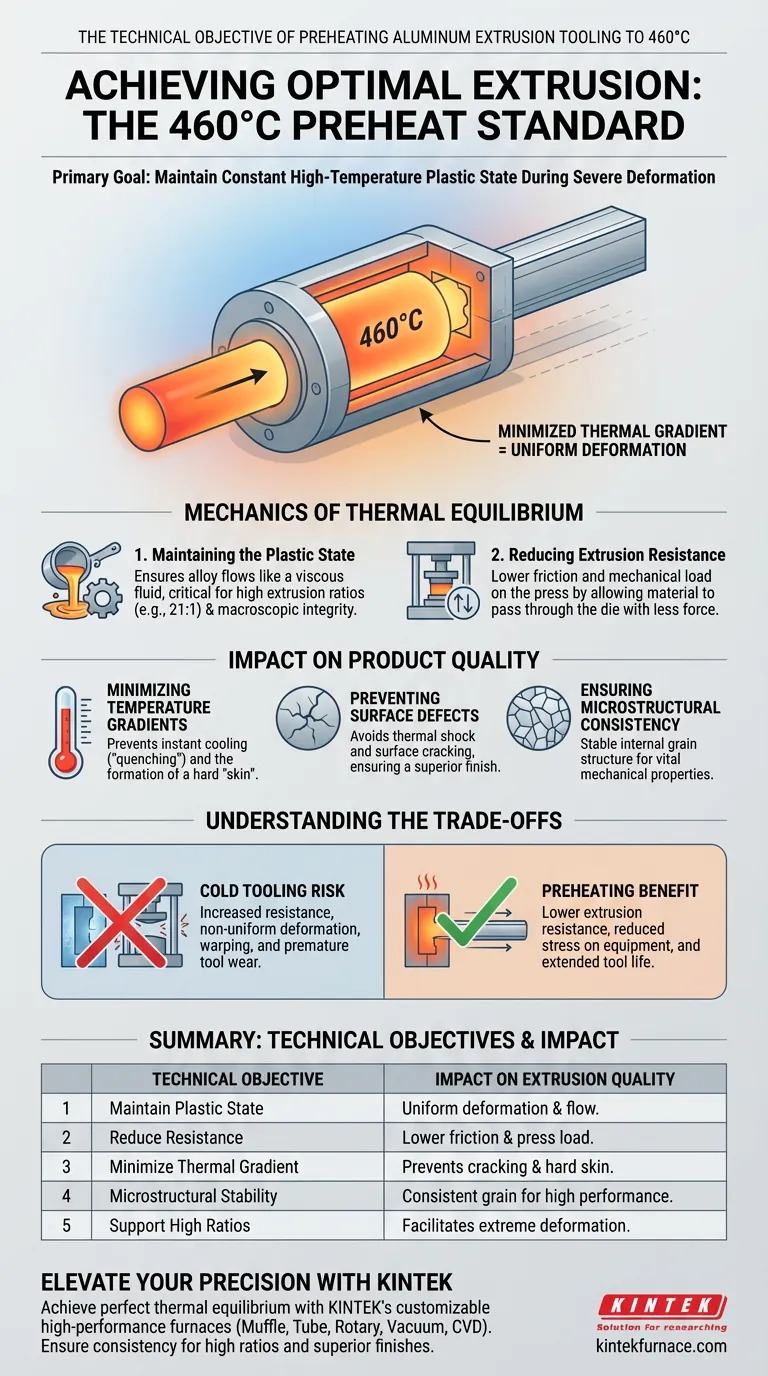

The primary technical objective of preheating the extrusion cylinder and molds to 460 ℃ is to strictly maintain the aluminum alloy in a constant, high-temperature plastic state during severe deformation. By equilibrating the temperature of the tooling with the material, you minimize the thermal gradient at the interface. This directly reduces extrusion resistance and eliminates the internal stresses that lead to non-uniform deformation or surface cracking.

Preheating is critical for achieving high extrusion ratios, such as 21:1, without compromising the material structure. It ensures the extruded bars retain both macroscopic integrity and microstructural consistency.

Mechanics of Thermal Equilibrium

Maintaining the Plastic State

For aluminum alloys to be extruded successfully, they must flow similarly to a viscous fluid. Preheating the cylinder and molds ensures the alloy remains in a high-temperature plastic state throughout the entire process.

Reducing Extrusion Resistance

When the tooling is as hot as the billet, the friction and resistance against the metal flow are significantly lowered. This allows the material to pass through the die with less force, reducing the mechanical load on the extrusion press.

Impact on Product Quality

Minimizing Temperature Gradients

If hot aluminum touches a cold mold, the outer layer of the metal cools instantly (quenching), creating a hard "skin" while the core remains soft. Preheating to 460 ℃ prevents this drastic temperature difference.

Preventing Surface Defects

Large temperature differences often result in surface cracking. By minimizing the thermal gradient, the material deforms uniformly, preventing the surface tears that ruin the finish of the extruded bar.

Ensuring Microstructural Consistency

Beyond the visible surface, the internal grain structure of the metal relies on stable temperatures. Uniform heating ensures the microstructure remains consistent from the core to the surface, which is vital for the mechanical properties of the final part.

Understanding the Trade-offs

The Risk of Cold Tooling

Failing to reach the target temperature of 460 ℃ does not just result in poor surface finish; it risks the integrity of the process itself.

Mechanical Stress and Wear

Attempting to force hot metal through cooler tooling increases extrusion resistance. This not only requires higher pressure but can also lead to non-uniform deformation, potentially causing the part to warp or the tooling to suffer premature wear.

Making the Right Choice for Your Goal

To maximize the quality of your aluminum extrusion process, control of the preheating phase is non-negotiable.

- If your primary focus is Surface Finish: Ensure the mold temperature precisely matches the alloy temperature to prevent the thermal shock that causes surface cracks.

- If your primary focus is Structural Integrity: Maintain the 460 ℃ target to guarantee uniform microstructural evolution, especially when targeting high extrusion ratios like 21:1.

- If your primary focus is Equipment Longevity: Prioritize preheating to lower extrusion resistance, which reduces the stress placed on both the cylinder and the die.

Consistency in temperature is the defining factor between a flawed component and a high-performance structural element.

Summary Table:

| Technical Objective | Impact on Extrusion Quality |

|---|---|

| Maintain Plastic State | Ensures alloy flows like a viscous fluid for uniform deformation. |

| Reduce Resistance | Lowers friction and mechanical load on the extrusion press. |

| Minimize Thermal Gradient | Prevents surface cracking and the formation of a hard "skin." |

| Microstructural Stability | Ensures internal grain consistency for high-performance mechanical properties. |

| Support High Ratios | Facilitates extreme deformation (e.g., 21:1) without material failure. |

Elevate Your Metal Processing Precision with KINTEK

Achieving perfect thermal equilibrium in aluminum extrusion requires reliable, high-performance heating solutions. Backed by expert R&D and manufacturing, KINTEK offers a wide range of systems, including Muffle, Tube, Rotary, Vacuum, and CVD furnaces, all fully customizable to meet your unique high-temperature needs. Whether you are targeting high extrusion ratios or superior surface finishes, our technology provides the consistency your materials demand.

Contact KINTEK today to discover how our specialized laboratory and industrial furnaces can optimize your production and ensure structural integrity.

Visual Guide

References

- Influence of Aging Temperature on the Electrochemical Corrosion Behavior of an Age-Hardening 7xxx Aluminum Alloy. DOI: 10.3390/cryst15020107

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the significance of a flow control system for safety during the in-situ passivation of U-6Nb powders?

- What are the limitations of functional group grafting through high-temperature heating? Achieve Chemical Precision

- Why is a constant temperature water bath or hot plate required for MXene post-treatment? Master Precise Delamination

- What role does the vacuum system play in regulating the length of ZnO branches? Master Precision in Nanostructures

- What functions does ammonia (NH3) perform beyond acting as a nitrogen source? Unlock Advanced Surface Engineering

- Why is it important to choose the right type of heat treatment furnace? Boost Efficiency and Quality in Your Lab or Facility

- What are the primary applications of a high-precision electric furnace in biomass characterization? Unlock Key Insights

- What are the three main categories of thin-film deposition methods? Essential Guide for Material Engineers