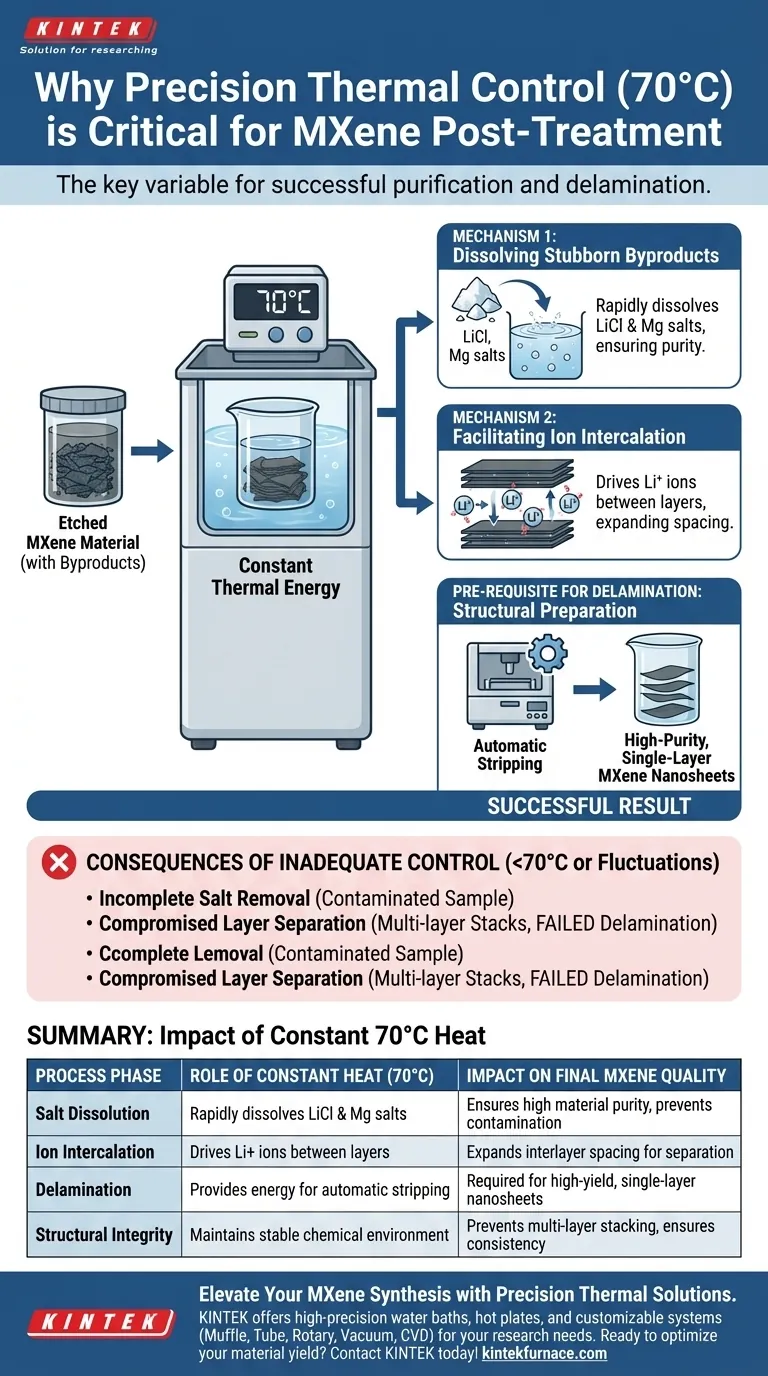

Precision thermal control is the critical variable for successful MXene purification. A constant temperature water bath or hot plate is required to provide the stable thermal energy needed to dissolve residual salts in 70°C water effectively. This specific thermal environment ensures the rapid dissolution of byproducts like lithium chloride and magnesium salts, while simultaneously enabling solvated lithium ions to diffuse between the material layers.

The application of constant heat is not just a cleaning measure; it is a structural preparation step. It facilitates the necessary ion diffusion that acts as a prerequisite for the automatic stripping and delamination of MXene into single-layer sheets.

The Mechanics of Post-Etching Purification

Dissolving Stubborn Byproducts

The etching process leaves behind significant residual byproducts, specifically lithium chloride and magnesium salts. These compounds can be difficult to remove completely at room temperature.

By utilizing a water bath or hot plate to maintain a constant temperature of 70°C, you ensure these salts dissolve rapidly. This prevents impurities from remaining on the surface or between the layers of the synthesized material.

Facilitating Ion Intercalation

The heating process serves a dual purpose beyond simple washing. It provides the energy required for solvated lithium ions to effectively diffuse into the MXene layers.

This intercalation of lithium ions is a chemical necessity for the material's final structure. It expands the interlayer spacing, preparing the tightly packed stacks for separation.

Preparing for Delamination

The Prerequisite for Stripping

The ultimate goal of synthesis is often to obtain individual, single-layer MXene sheets. The thermal treatment described is the essential "key" that unlocks this possibility.

Without the effective diffusion of lithium ions driven by stable heat, the subsequent automatic stripping process will likely fail. The material must be chemically prepped by this thermal step to allow for successful delamination.

Consequences of Inadequate Thermal Control

Incomplete Salt Removal

If the temperature fluctuates or fails to reach the required 70°C threshold, salt dissolution becomes inefficient. Residual magnesium or lithium salts may contaminate the final sample, altering its electrical or physical properties.

Compromised Layer Separation

The most significant trade-off of neglecting this step is a failure in the delamination phase. If the thermal energy is insufficient to drive lithium ion diffusion, the layers may remain stuck together. This renders the automatic stripping process ineffective, yielding multi-layer stacks rather than the desired individual nanosheets.

Optimizing Your MXene Synthesis

Making the Right Choice for Your Goal

- If your primary focus is material purity: Ensure your water bath maintains a strict 70°C to guarantee the complete dissolution of lithium chloride and magnesium salt residues.

- If your primary focus is high-yield delamination: Prioritize this thermal step to maximize lithium ion diffusion, which is the mechanical prerequisite for separating individual layers.

Consistent thermal energy is the bridge between a raw etched product and a high-quality, delaminated nanomaterial.

Summary Table:

| Process Phase | Role of Constant Heat (70°C) | Impact on Final MXene Quality |

|---|---|---|

| Salt Dissolution | Rapidly dissolves LiCl and magnesium salts | Ensures high material purity and prevents surface contamination |

| Ion Intercalation | Drives solvated Li+ ions between material layers | Expands interlayer spacing for easier separation |

| Delamination | Provides energy for automatic stripping | Required for obtaining high-yield, single-layer nanosheets |

| Structural Integrity | Maintains stable chemical environment | Prevents multi-layer stacking and inconsistent electrical properties |

Elevate Your MXene Synthesis with Precision Thermal Solutions

Achieving perfect delamination and high-purity nanosheets requires more than just chemistry; it requires uncompromising thermal stability. KINTEK provides the specialized lab equipment needed to maintain the exact 70°C environment critical for lithium ion diffusion and salt removal.

Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory equipment including high-precision water baths, hot plates, and advanced Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are working on 2D materials or high-temp industrial applications, our solutions are fully customizable for your unique research needs.

Ready to optimize your material yield? Contact KINTEK today to find the perfect thermal system for your lab!

Visual Guide

References

- Sin‐Yi Pang, Jianhua Hao. Fluoride‐Free Molten Salt Hydrate‐Assisted Synthesis of MXene in Air Down to 150 °C. DOI: 10.1002/adfm.202504864

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is programmable temperature control in furnaces critical during superalloy aluminization? Ensure High-Yield HTLA

- Why must (MnFeNiCo)3O4 materials undergo a secondary calcination? Key Steps to Optimizing FCC Spinel Structure

- How does substrate preheating equipment affect the formation and distribution of the Laves phase in Inconel 718?

- What advantages does hydrogen gas-phase pyrolysis offer over inert gas? Unlock Superior Carbon Defunctionalization

- What role does high-temperature calcination play in the purification of volcanic ash? Achieve Ultra-Pure Silica Results

- How does a lab furnace use eutectic points for Boron Carbide sintering? Achieve High-Density Ceramics at Lower Heat

- How does a laboratory furnace affect chemical bonding in hybrid composites? Unlock Superior Material Strength

- Why are batch furnaces considered essential for certain applications? Achieve Precision and Flexibility in Heat Treatment