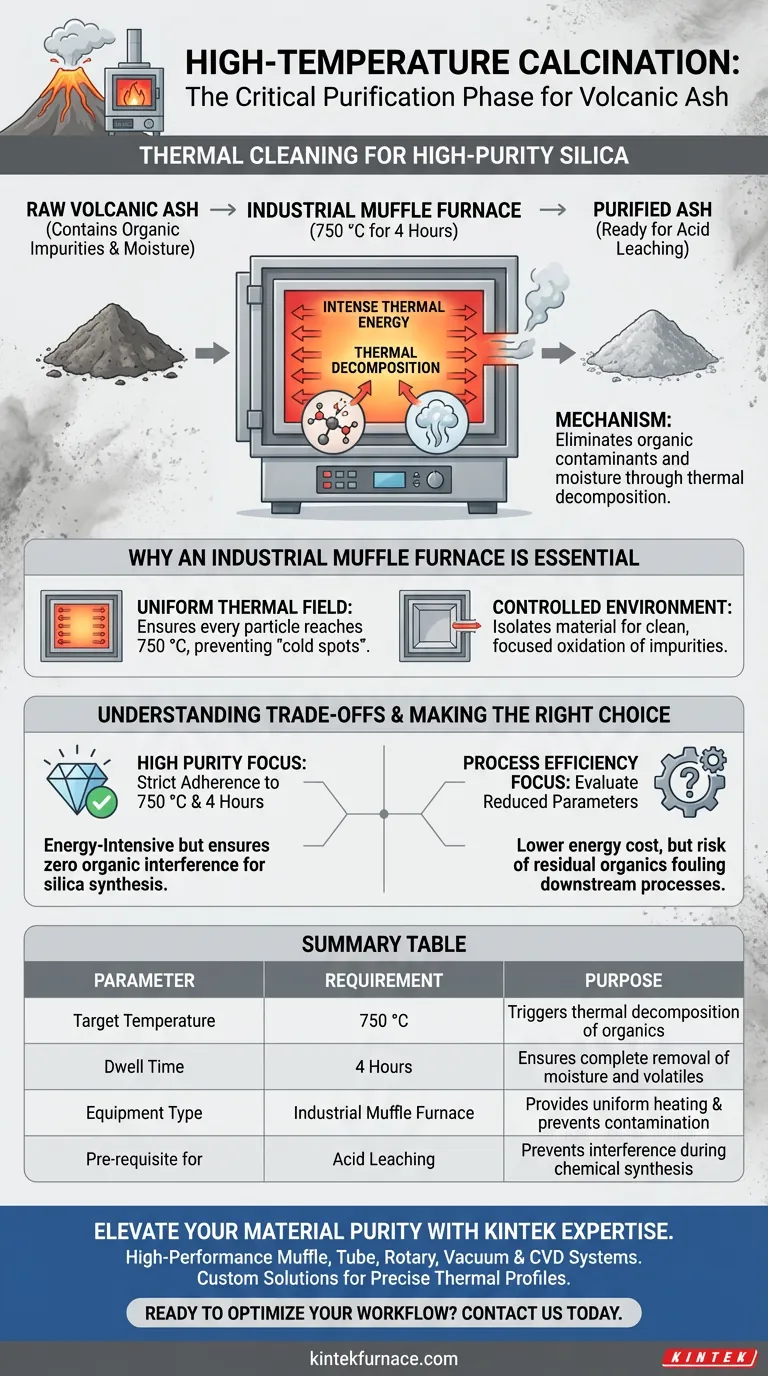

High-temperature calcination serves as the critical thermal cleaning phase in the processing of volcanic ash. By subjecting the material to 750 °C for four hours within an industrial muffle furnace, the process utilizes intense thermal energy to decompose and eliminate organic impurities and residual moisture. This step is a mandatory precursor to acid leaching, ensuring that contaminants do not interfere with the subsequent synthesis of high-purity silica.

Core Takeaway Calcination is not merely a drying step; it is a chemical purification process that uses thermal decomposition to strip away organic matter. By removing these impurities upfront, you protect the integrity of the downstream acid leaching process and ensure the final synthesized silica meets high purity standards.

The Mechanism of Thermal Purification

Eliminating Organic Contaminants

Volcanic ash naturally contains organic impurities and moisture that act as contaminants. The primary function of calcination is to subject these unwanted elements to temperatures high enough to trigger thermal decomposition.

The Specifics of the Thermal Profile

For volcanic ash, the established protocol requires a sustained temperature of 750 °C for a duration of four hours. This specific time-temperature profile ensures that the decomposition of organics is complete rather than partial.

Preparing for Acid Leaching

This purification is a prerequisite for the next stage: acid leaching. If organic impurities remain in the ash, they can react unpredictably during leaching, compromising the efficiency of the chemical reaction and the purity of the final product.

Why the Industrial Muffle Furnace is Essential

Providing Consistent Thermal Energy

An industrial muffle furnace is designed to provide a uniform thermal field. This ensures that every particle of the volcanic ash is exposed to the same temperature, preventing "cold spots" where impurities might survive.

Controlled Environment

The muffle design isolates the material from direct contact with fuel or combustion byproducts. This allows for a clean, controlled application of heat focused solely on oxidizing and removing the target impurities.

Understanding the Trade-offs

Energy Consumption vs. Purity

Running a furnace at 750 °C for four hours is energy-intensive. While this ensures high purity, it represents a significant operational cost that must be weighed against the required grade of the final silica.

The Risk of Thermal Variation

While the target is 750 °C, process control is vital. As seen in similar calcination processes, significant temperature fluctuations can lead to abnormal structural changes or incomplete removal of solvents, necessitating precise equipment calibration.

Making the Right Choice for Your Project

To determine how strictly you must adhere to this calcination protocol, consider your end-goal requirements.

- If your primary focus is High-Purity Silica Synthesis: Adhere strictly to the 750 °C and 4-hour parameters to ensure zero organic interference during acid leaching.

- If your primary focus is Process Efficiency: Evaluate if lower-grade applications allow for a reduced temperature or dwell time, but be aware that residual organics may foul downstream chemical processes.

Successful purification relies on viewing calcination not as a passive heating step, but as an active chemical barrier against contamination.

Summary Table:

| Process Parameter | Requirement | Purpose in Purification |

|---|---|---|

| Target Temperature | 750 °C | Triggers thermal decomposition of organics |

| Dwell Time | 4 Hours | Ensures complete removal of moisture and volatiles |

| Equipment Type | Industrial Muffle Furnace | Provides uniform heating and prevents contamination |

| Pre-requisite for | Acid Leaching | Prevents interference during chemical synthesis |

Elevate Your Material Purity with KINTEK Expertise

Don't let organic contaminants compromise your silica synthesis. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to deliver the precise thermal profiles required for critical calcination processes. Whether you need a standard setup or a fully customizable high-temp furnace for your unique research needs, our engineering team is ready to help you achieve superior thermal uniformity and process control.

Ready to optimize your purification workflow? Contact us today to find the perfect furnace solution for your lab.

Visual Guide

References

- Raden Darmawan, Fitria Nur Laily. Silica Synthesis from Mount Semeru Volcanic Ash as a Nickel Heavy Metal Adsorbent. DOI: 10.9767/bcrec.20337

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is an electric blast drying oven required for CRP microstructure analysis? Ensure Data Accuracy with Proper Drying

- What is the purpose of using an Argon Stream during activation? Enhance $CO_2$ Adsorption Efficiency

- Why is precise temperature control in an aging oven critical for ZK61 alloys? Master the 175°C Pre-aging Threshold

- Why is graphene oxide (GO) essential in microwave synthesis? Unlock Rapid Growth and Precise 2D Nanocomposite Control

- Why is a forced-air drying oven necessary for impregnated kaolin catalysts? Achieve Uniform Component Immobilization

- What is the significance of high-precision temperature monitoring systems in SPS? Control Ti-6Al-4V/HA Microstructure

- What is the synergistic effect of industrial fly ash in beet pulp porous carbons? Enhance 3D Structural Performance

- Why is high-purity argon gas required for MTO synthesis? Ensure Stability in Rhenium Organometallic Catalysis