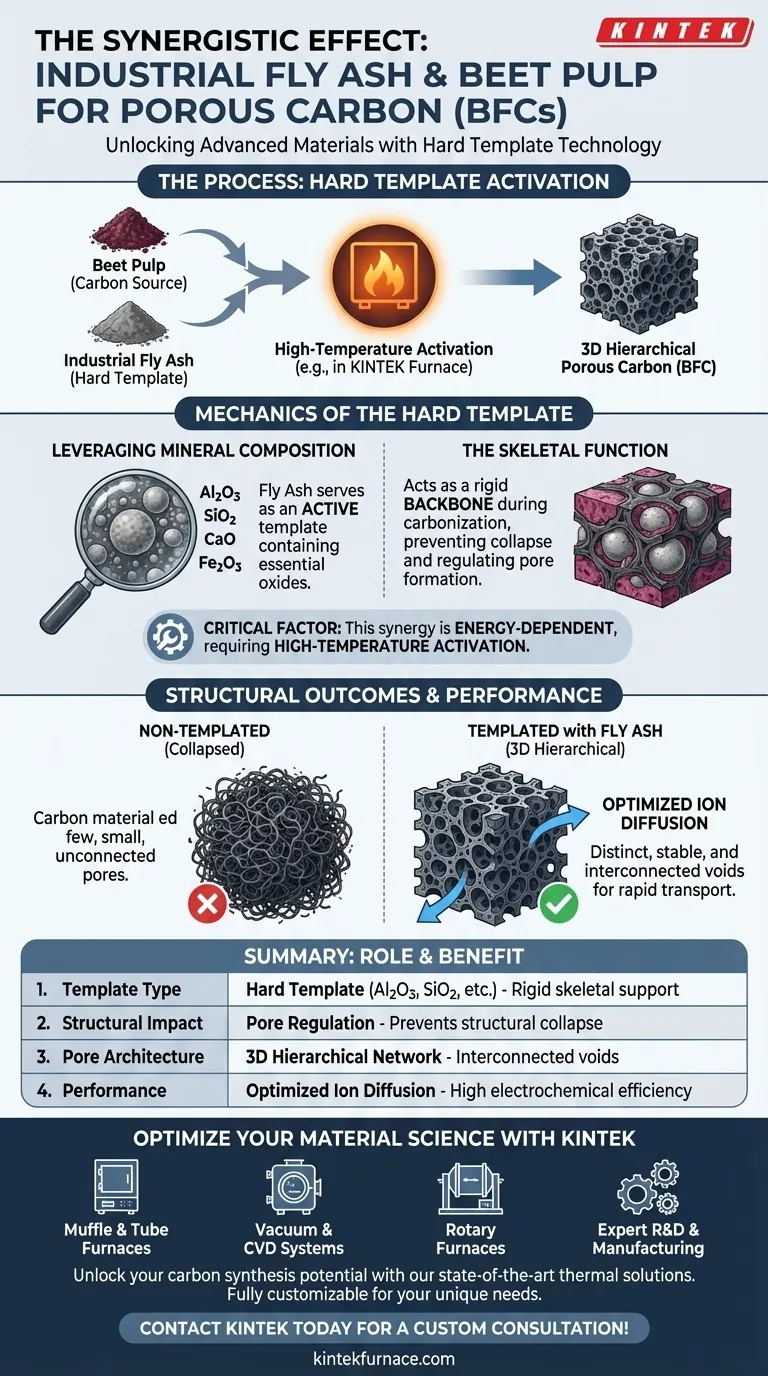

The synergistic effect arises from the physical scaffolding provided by industrial fly ash during the carbonization of beet pulp. The fly ash acts as a "hard template," utilizing its mineral composition to regulate pore formation during high-temperature activation. This interaction prevents structural collapse and organizes the carbon into a highly functional network.

The integration of fly ash provides a critical skeletal function that creates a stable 3D hierarchical porous structure, directly resulting in significantly improved ion diffusion efficiency.

The Mechanics of the Hard Template

Leveraging Mineral Composition

The synergy begins with the specific chemical makeup of the industrial fly ash.

It is not an inert filler but serves as an active template containing Al2O3, SiO2, CaO, and Fe2O3. These oxides are essential to the templating process.

The Skeletal Function

During the critical phase of high-temperature activation, the fly ash provides a skeletal function.

As the beet pulp converts to carbon, the fly ash acts as a rigid backbone. This regulates the formation of pores and ensures the material maintains a defined shape rather than collapsing into a dense mass.

Structural Outcomes and Performance

Creating a 3D Hierarchical Structure

The primary output of this template-assisted technology is the construction of a stable 3D hierarchical porous structure.

This architecture is distinct from the disordered pore structures typically found in non-templated carbonization. It offers a sophisticated network of interconnected voids.

Optimizing Ion Diffusion

The ultimate advantage of this structural synergy is electrochemical performance.

Because the pores are regulated and hierarchically organized, the material exhibits significantly improved diffusion efficiency of ions. This makes the material highly effective for applications requiring rapid transport of species within the carbon matrix.

Understanding the Process Dependencies

Reliance on High-Temperature Activation

It is important to note that this synergy is energy-dependent.

The skeletal function and pore regulation described do not occur passively. They explicitly require high-temperature activation to facilitate the interaction between the mineral template and the beet pulp carbon source.

Making the Right Choice for Your Goal

- If your primary focus is Structural Stability: Rely on the fly ash's skeletal function to prevent pore collapse and maintain a robust 3D framework.

- If your primary focus is Electrochemical Performance: Leverage this templating method to maximize ion diffusion efficiency through the creation of hierarchical pores.

By using fly ash as a hard template, you convert agricultural waste into a high-performance material with an optimized internal architecture.

Summary Table:

| Feature | Role of Fly Ash Synergy | Benefit to Porous Carbon |

|---|---|---|

| Template Type | Hard Template (Al2O3, SiO2, etc.) | Provides rigid skeletal support |

| Structural Impact | Pore Regulation | Prevents structural collapse during activation |

| Pore Architecture | 3D Hierarchical Network | Creates interconnected voids for transport |

| Performance | Optimized Ion Diffusion | High electrochemical efficiency |

Optimize Your Material Science with KINTEK Advanced Thermal Solutions

Unlock the full potential of your carbon synthesis research with KINTEK. Our state-of-the-art laboratory equipment is designed to handle the rigorous demands of high-temperature activation and templating processes.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance systems, including:

- Muffle and Tube Furnaces for precise carbonization

- Vacuum and CVD Systems for advanced material engineering

- Rotary Furnaces for uniform processing

All our systems are fully customizable to meet your unique research and industrial needs. Whether you are developing sustainable porous carbons or exploring new chemical synergies, our technology provides the stability and control your project deserves.

Ready to elevate your lab's capabilities? Contact KINTEK today for a custom consultation!

Visual Guide

References

- Perseverance Dzikunu, Pedro Vilaça. Waste-to-carbon-based supercapacitors for renewable energy storage: progress and future perspectives. DOI: 10.1007/s40243-024-00285-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What role does a vacuum oven play in determining the moisture content of mercury-depleted coal adsorbents? Key Insights

- What is the purpose of using a forced-air drying oven at 100 °C? Optimize Fe3O4@Fe-AC Composite Synthesis

- What is the function of a furnace in CuAlMn alloy treatment? Achieve Perfect Microstructural Homogenization

- Why is high raw material purity essential for magnesium alloy research? Ensure Precise Thermodynamic Data Quality

- Why is thermal growth oxidation preferred for SiO2 gate dielectrics? Superior Quality for a-IGZO TFTs

- What are the advantages of solution combustion synthesis? Optimize (MnFeNiCoX)3O4 High-Entropy Oxide Catalyst Production

- How does a high-sensitivity non-contact microphone assist in detecting cracks during the solidification of molten slag?

- Why is a 1:1 mixture of NaNO3 and KNO3 used in molten salt baths? Optimize Quenching Performance