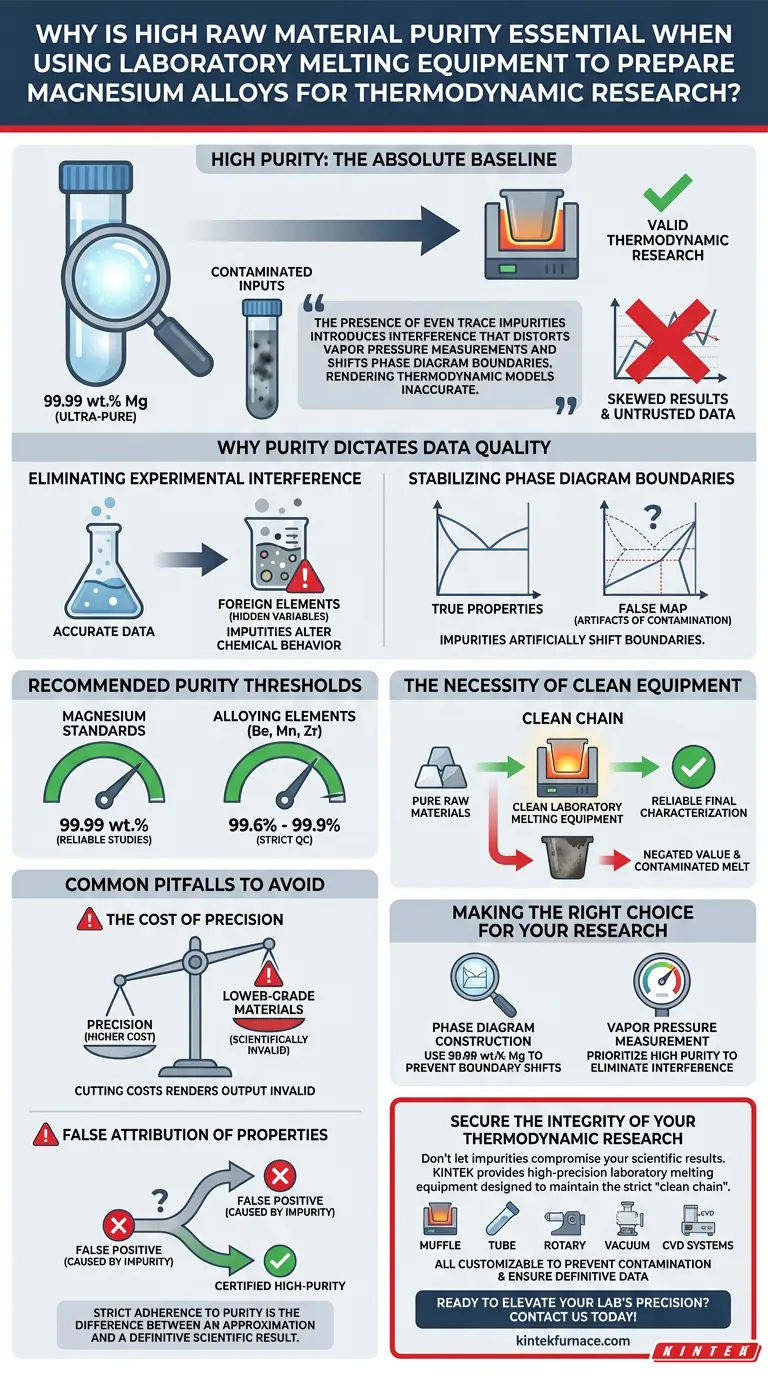

High raw material purity is the absolute baseline for valid thermodynamic research. When preparing magnesium alloys in laboratory melting equipment, using ultra-pure inputs—such as 99.99 wt.% magnesium—is essential to prevent contaminants from skewing experimental results. Without this strict standard, the resulting data cannot be trusted for scientific characterization.

The presence of even trace impurities introduces interference that distorts vapor pressure measurements and shifts phase diagram boundaries, rendering thermodynamic models inaccurate.

Why Purity Dictates Data Quality

Eliminating Experimental Interference

Impurities are not inert; they actively alter the chemical behavior of the melt. To obtain accurate thermodynamic data, you must remove these hidden variables from the equation.

If low-purity materials are used, the interference from foreign elements will mask the true properties of the alloy.

Stabilizing Phase Diagram Boundaries

Calculating phase diagram boundaries requires extreme precision. Impurities can artificially shift these boundaries, creating a false map of the alloy's material phases.

High purity ensures that the boundaries you observe are inherent to the alloy system, not artifacts of contamination.

Recommended Purity Thresholds

Magnesium Standards

For the base metal, a purity of 99.99 wt.% is the standard required to ensure reliability in thermodynamic studies.

Alloying Elements

Secondary elements also require strict quality control. Materials such as beryllium, manganese, and zirconium typically require purity levels between 99.6% and 99.9%.

The Necessity of Clean Equipment

Maintaining the "Clean Chain"

High-purity raw materials must be processed in clean laboratory melting equipment.

Introducing pure metals into a contaminated crucible or furnace negates the value of the raw material.

Ensuring Characterization Reliability

The combination of pure materials and clean equipment is the only way to guarantee the reliability of the final alloy characterization.

Common Pitfalls to Avoid

The Cost of Precision

Achieving these purity levels requires sourcing specialized, often more expensive materials.

While this increases upfront resource allocation, attempting to cut costs with lower-grade materials renders the research output scientifically invalid.

False Attribution of Properties

A common error in thermodynamic research is attributing a specific behavior to the alloy when it is actually caused by an impurity.

Using certified high-purity stock is the only method to rule out this "false positive" data.

Making the Right Choice for Your Research

To ensure your thermodynamic data stands up to peer review, align your material selection with your specific research goals:

- If your primary focus is Phase Diagram Construction: Use 99.99 wt.% magnesium to ensure that phase boundaries are not shifted by trace contaminants.

- If your primary focus is Vapor Pressure Measurement: Prioritize high purity to eliminate interference that can distort pressure readings.

Strict adherence to material purity is the difference between an approximation and a definitive scientific result.

Summary Table:

| Feature | Recommended Purity | Scientific Impact |

|---|---|---|

| Base Magnesium | 99.99 wt.% | Prevents phase boundary shifts and data artifacts |

| Alloying Elements | 99.6% - 99.9% | Ensures accurate vapor pressure measurements |

| Melting Equipment | Laboratory Grade | Prevents cross-contamination of ultra-pure melts |

| Research Goal | Phase Construction | Guarantees reliability for peer-reviewed characterization |

Secure the Integrity of Your Thermodynamic Research

Don't let impurities compromise your scientific results. KINTEK provides high-precision laboratory melting equipment designed to maintain the strict 'clean chain' required for sensitive magnesium alloy preparation.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to prevent contamination and ensure your research data is definitive.

Ready to elevate your lab's precision? Contact us today to find your custom furnace solution!

Visual Guide

References

- В. Н. Володин, Xeniya Linnik. Recycling of beryllium, manganese, and zirconium from secondary alloys by magnesium distillation in vacuum. DOI: 10.31643/2024/6445.42

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why are high-precision nitrogen flow meters essential during pyrolysis? Ensure Perfect Char Preparation

- What is an industrial oven and which industries use it? Discover Versatile Thermal Processing Solutions

- What is the specific function of laboratory electric heating devices in solid-state hydrogen storage? Optimize Thermal Management

- What is the primary purpose of introducing reactive gases (SF6/CF4) in magnetron sputtering? Restore Film Stoichiometry

- How does the QIO algorithm improve temperature control precision in electric furnaces? Achieve Global Optimization

- What is the operating principle of a vacuum freeze-dryer in the fabrication of carbon aerogels? Master Sublimation

- What is the primary function of carbonization equipment? Master Biomass to Fuel Conversion with Precision

- What performance characteristics are required for a stainless steel tubular autoclave or reactor used in SCWG?