High-sensitivity non-contact microphones function as a remote diagnostic tool, bridging the gap between extreme thermal environments and precision measurement. By eliminating the need for physical contact with molten slag, these devices capture the specific acoustic wave signals released the instant a crack initiates. This allows for the real-time detection of structural failures that traditional sensors, which cannot withstand direct contact with high-temperature slag, would miss.

By bypassing the thermal limitations of physical sensors, this technology isolates the precise moment of fracture during solidification. It enables researchers to correlate crack formation with specific crystalline or glassy phase transitions.

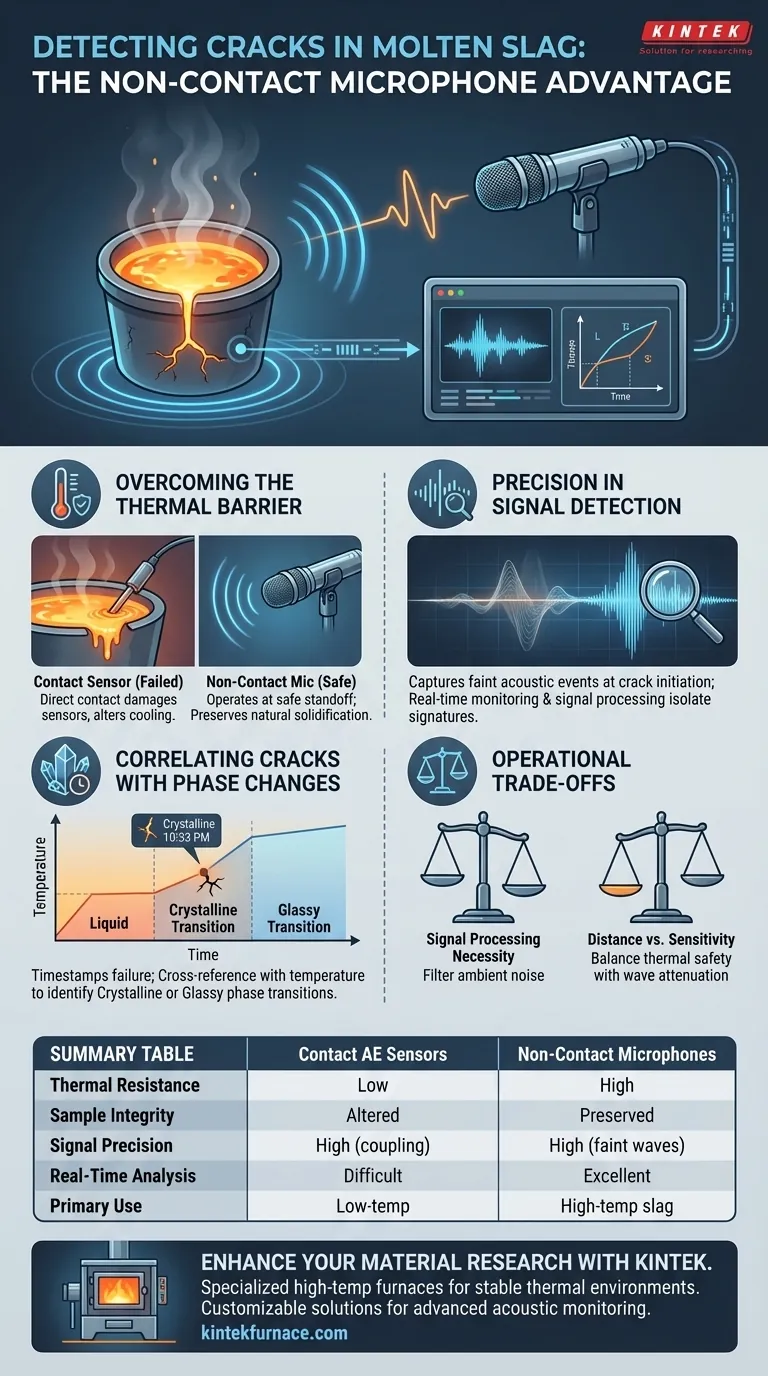

Overcoming the Thermal Barrier

The Limitation of Contact Sensors

Traditional Acoustic Emission (AE) sensors rely on direct physical contact to detect vibrations. In the context of molten slag, the extreme temperatures often damage these sensors or make consistent coupling impossible.

The Non-Contact Advantage

A non-contact microphone operates at a safe distance from the heat source. This separation ensures the equipment remains functional and accurate throughout the entire solidification process, regardless of the slag's temperature.

Preserving the Specimen

Because the sensor does not touch the slag, it does not act as a heat sink or alter the cooling rate. This ensures the solidification process observed is natural and undisturbed by the measurement tools.

Precision in Signal Detection

Capturing Faint Acoustic Waves

Crack initiation releases energy in the form of sound waves, often at very low amplitudes. High-sensitivity microphones are engineered to detect these faint, transient signals that indicate the very beginning of a fracture.

Real-Time Monitoring

The detection happens instantaneously. As the slag cools and stresses build, the microphone captures the acoustic event the moment it occurs, providing a real-time timeline of structural changes.

Leveraging Signal Processing

Raw acoustic data is often complex. By integrating this hardware with advanced processing technology, researchers can filter out background noise to isolate the specific signature of a crack.

Correlating Cracks with Phase Changes

Identifying the Transition Point

Slag solidification involves complex changes, moving between liquid, crystalline, and glassy states. The microphone provides the exact timestamp of a crack.

Mapping to Microstructure

By knowing the exact time a crack formed, researchers can cross-reference that moment with the slag's temperature profile. This reveals whether the failure occurred during a crystalline transition or a glassy transition.

Understanding Failure Mechanisms

This correlation helps identify which specific phase of cooling is most susceptible to cracking. It moves the analysis from simply knowing that a crack occurred to understanding why it occurred relative to the material's structure.

Understanding the Operational Trade-offs

Necessity of Signal Processing

High sensitivity means the microphone picks up everything, potentially including ambient environmental noise. Reliable results depend heavily on the quality of the signal processing technology used to filter out non-relevant sounds.

Distance vs. Sensitivity

While non-contact is safer, acoustic waves attenuate (weaken) as they travel through air. The microphone must be positioned carefully to balance thermal safety with the ability to detect very faint crack signatures.

Maximizing Insight from Solidification Data

To effectively utilize this technology, align your equipment choice with your specific research objectives.

- If your primary focus is material characterization: Prioritize systems with high temporal resolution to accurately map cracks to specific crystalline or glassy phases.

- If your primary focus is equipment longevity: Ensure the microphone's sensitivity is high enough to allow for a standoff distance that protects the sensor from radiant heat.

This technology transforms the chaotic sounds of cooling slag into a precise map of material behavior.

Summary Table:

| Feature | Contact AE Sensors | Non-Contact Microphones |

|---|---|---|

| Thermal Resistance | Limited; prone to heat damage | High; safe standoff distance |

| Sample Integrity | Acts as a heat sink; alters cooling | No contact; preserves natural cooling |

| Signal Precision | High, but requires coupling agents | High; detects faint transient waves |

| Real-Time Analysis | Difficult in extreme heat | Excellent; captures instant fracture |

| Primary Use | Lower temperature vibrations | High-temp slag solidification monitoring |

Enhance Your Material Research with KINTEK

Precision in high-temperature analysis requires equipment that can withstand the heat while delivering accurate data. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding laboratory environments. Whether you are studying crystalline transitions in slag or developing new alloys, our customizable high-temp furnaces provide the stable thermal environment necessary for advanced acoustic monitoring.

Ready to optimize your solidification studies? Contact us today to discover how KINTEK’s tailored solutions can support your unique research needs.

Visual Guide

People Also Ask

- What are the functions of an industrial drying furnace vertically installed below a shredder? Efficient LIB Recycling

- What are the equipment requirements for high-temperature furnaces during magnetic biochar synthesis? Find the key specs.

- How does the pre-oxidation process affect high-temperature alloys? Enhancing Surface Integrity for Steam Cracking

- What is the mechanism of bed powder in LLZO sintering? Optimize Lithium Stability and Phase Purity

- How does a high-precision Vertical Bridgman Furnace facilitate ZnGeP2 growth? Master Single Crystal Production

- How does a crucible furnace work? A Guide to Efficient Metal Melting

- What type of furnace is used for heat treatment? Choose the Right Solution for Your Materials

- What is the significance of using a hydrogen etching process in a reaction chamber? Mastering SiC Surface Preparation