The critical equipment requirement for high-temperature furnaces in magnetic biochar synthesis is the capability to establish and maintain a completely hermetic, oxygen-free environment. Whether employing a box furnace or a tube furnace, the equipment must feature superior sealing mechanisms and precise atmosphere control to sustain a nitrogen blanket at operating temperatures of approximately 400°C.

The success of magnetic biochar synthesis is defined not just by heat, but by the exclusion of oxygen. Your furnace must guarantee an inert environment to prevent carbon loss and ensure iron oxides reduce specifically to the strongly magnetic Fe3O4 phase.

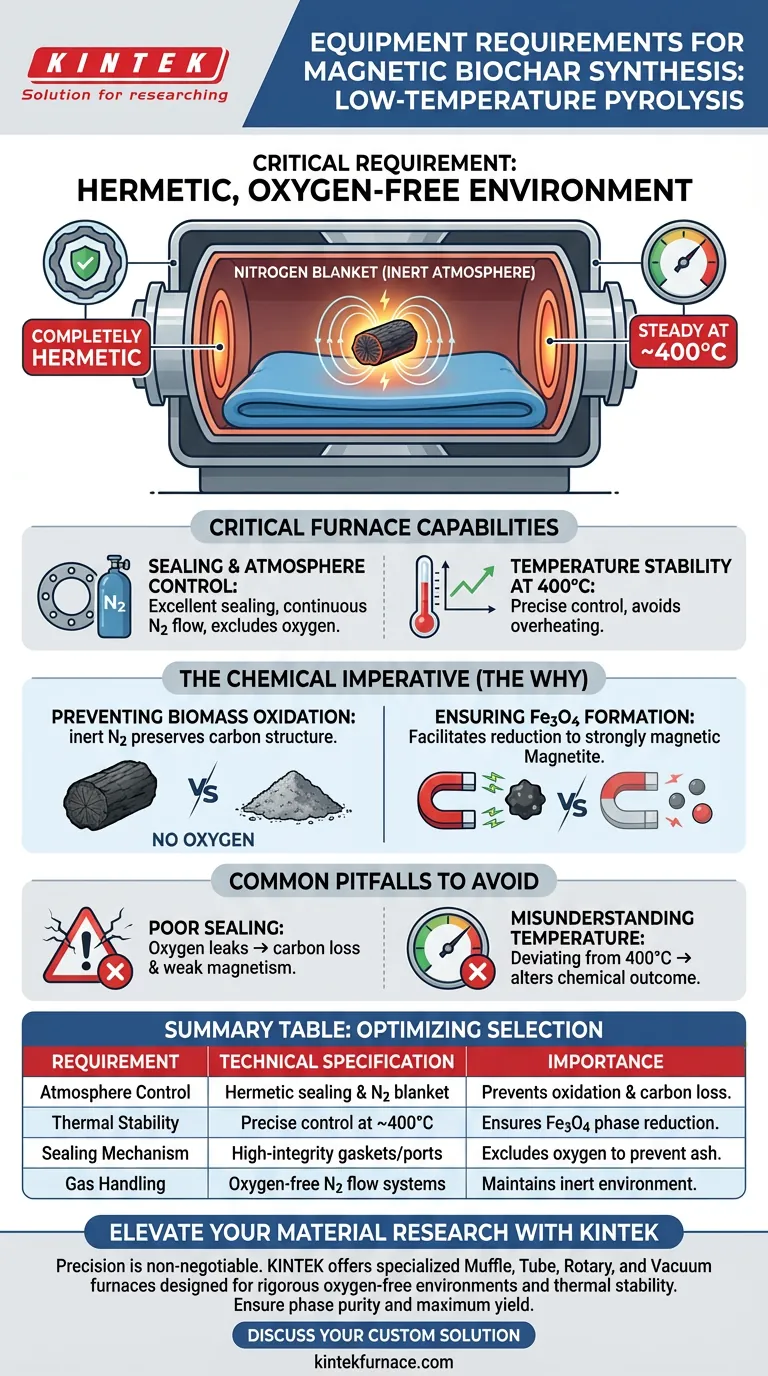

Critical Furnace Capabilities

To achieve successful low-temperature pyrolysis, the hardware must go beyond simple heating. It must serve as a reactor that strictly controls the chemical environment.

Sealing and Atmosphere Control

The furnace must possess excellent sealing capabilities. Standard furnaces with leaky door gaskets or unsealed ports are unsuitable for this process.

The system must support the continuous introduction of oxygen-free nitrogen. This creates an inert atmosphere that is maintained throughout the entire heating duration.

Temperature Stability at 400°C

While the equipment is classified as a "high-temperature furnace," this specific process requires stability at a lower range, typically around 400°C.

The furnace must be able to hold this temperature consistently. This thermal stability is required to drive the pyrolysis reaction without overheating the material or causing unwanted phase changes.

The Chemical Imperative

Understanding the "why" behind these equipment specs helps in selecting the right tool. The equipment requirements are dictated strictly by the chemical reactions needed to create magnetic properties.

Preventing Biomass Oxidation

If the furnace allows oxygen ingress, the biomass carbon will be consumed by oxidation.

Instead of forming biochar, the material will combust into ash. A strictly inert nitrogen environment preserves the carbon structure of the biomass.

Ensuring Fe3O4 Formation

The defining characteristic of magnetic biochar is the presence of Fe3O4 (Magnetite).

The furnace environment must facilitate the reduction of iron oxides into this specific strongly magnetic phase. If the atmosphere is uncontrolled, the process may yield non-magnetic impurities instead.

Common Pitfalls to Avoid

Even with high-quality equipment, overlooking the specific requirements of magnetic biochar synthesis can lead to failure.

The Risk of Poor Sealing

Using a furnace with degraded seals is the most common failure point. Even a small amount of oxygen can disrupt the reduction process.

This leads to the formation of weak magnetic phases or the total loss of the carbon matrix.

Misunderstanding Temperature Impact

Setting the temperature significantly higher or lower than the 400°C target can alter the chemical outcome.

Precision in the thermal setpoint is necessary to hit the specific reduction window for Magnetite.

Optimizing Your Equipment Selection

When evaluating furnaces for this application, prioritize atmospheric integrity over maximum temperature capabilities.

- If your primary focus is Phase Purity: Ensure the furnace has a verified, high-integrity sealing system to guarantee the formation of Fe3O4 rather than non-magnetic oxides.

- If your primary focus is Yield: Prioritize precise nitrogen flow controls to prevent oxidation and strictly preserve the biomass carbon mass.

The right furnace acts as a protective vessel, shielding the delicate chemical transformation of iron and carbon from the destructive effects of oxygen.

Summary Table:

| Requirement | Technical Specification | Importance in Magnetic Biochar Synthesis |

|---|---|---|

| Atmosphere Control | Hermetic sealing & Nitrogen blanket | Prevents biomass oxidation and carbon loss. |

| Thermal Stability | Precise control at ~400°C | Ensures reduction of iron oxides to magnetic Fe3O4 phase. |

| Sealing Mechanism | High-integrity gaskets/ports | Excludes oxygen to prevent combustion into ash. |

| Gas Handling | Oxygen-free N2 flow systems | Maintains the inert environment throughout the process. |

Elevate Your Material Research with KINTEK

Precision is non-negotiable in magnetic biochar synthesis. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, and Vacuum furnaces designed to deliver the rigorous oxygen-free environments and thermal stability your synthesis requires. Whether you need standard CVD systems or fully customizable high-temperature solutions, our equipment ensures phase purity and maximum yield for your lab's unique needs.

Ready to optimize your pyrolysis process? Contact KINTEK today to discuss your custom furnace solution!

Visual Guide

References

- Ruixiang Wu, Qianwei Ke. Preparation and characterization of Ru-TiO<sub>2</sub>/PC/Fe<sub>3</sub>O<sub>4</sub> composite catalyst with enhanced photocatalytic performance and magnetic recoverability under simulated solar light. DOI: 10.1039/d4ra07712a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the necessity of baking electrode sheets in a vacuum oven? Ensure Battery Stability and Peak Performance

- How do microprocessor-controlled electric furnaces ensure the homogeneity of the Se80In5Te6Sb9 alloy?

- What are the technical advantages of using a pyrolysis furnace vs. an incinerator? Recover Value from Composites

- What is the function of a Teflon-lined autoclave in hydrothermal acid treatment? Enhance Catalyst Synthesis Efficiency

- Why are SiC fragments added in microwave sintering? Boost Heating Uniformity and Prevent Cracks in Porous Ceramics

- How does zinc chloride (ZnCl2) serve as a structural template? Engineering High-Porosity Nitrogen-Doped Carbon

- What occurs during the recrystallization stage of annealing? Restore Ductility and Reset Microstructure

- Why must the entire system be maintained at a high temperature during the filling process of a sodium heat pipe?