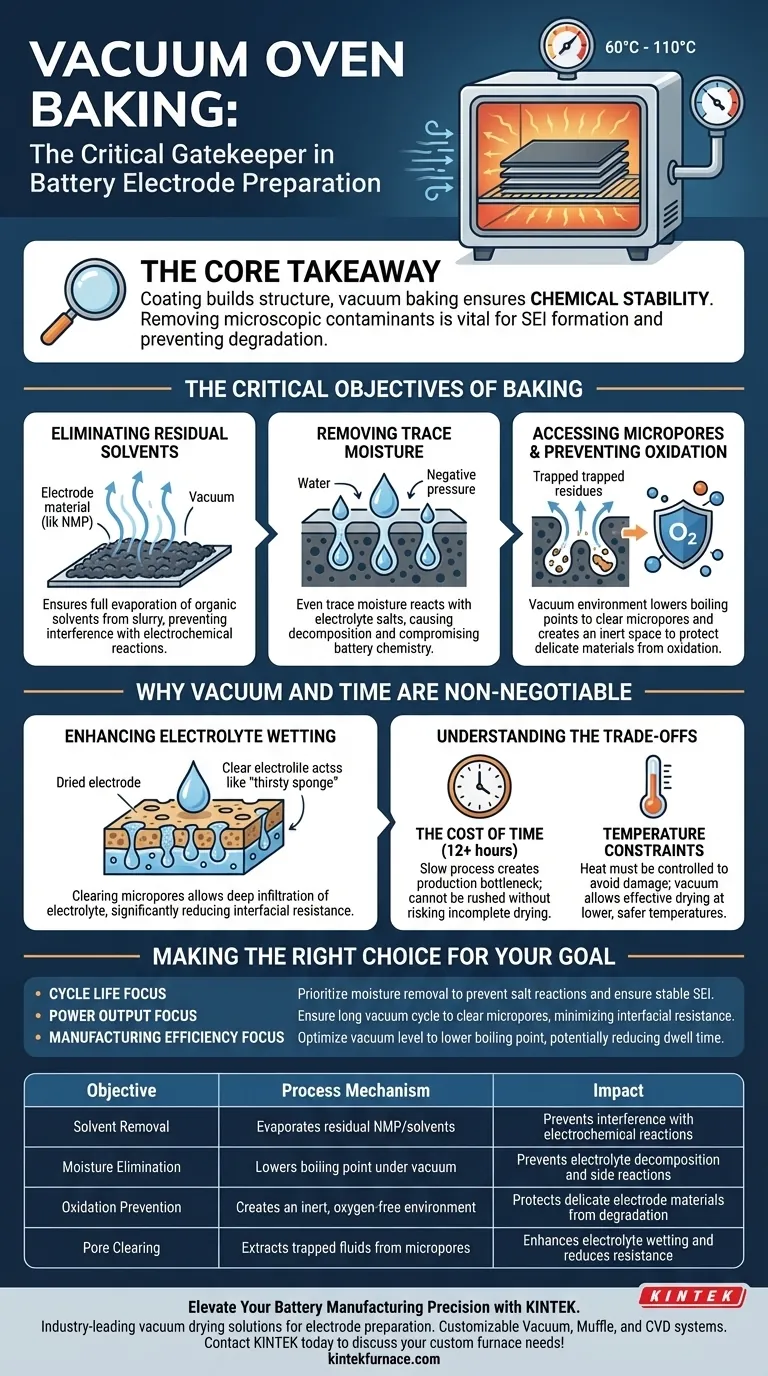

Baking electrode sheets in a vacuum oven is a critical purification step that functions as the final "gatekeeper" before cell assembly. By subjecting coated sheets to heat (typically 60°C to 110°C) under negative pressure for extended periods (often 12 hours or overnight), you ensure the complete extraction of residual polar organic solvents, such as NMP, and deep-seated trace moisture.

The Core Takeaway While coating builds the electrode's structure, vacuum baking ensures its chemical stability. Failing to remove microscopic contaminants leads to electrolyte decomposition and poor Solid Electrolyte Interface (SEI) formation, causing permanent degradation of battery performance and safety.

The Critical Objectives of Baking

Eliminating Residual Solvents

The coating process often relies on solvents like NMP (N-methyl-2-pyrrolidone) to create a slurry.

However, once the electrode is formed, these solvents become contaminants.

Extended baking ensures these organic solvents are fully evaporated from the material, preventing them from interfering with the cell's electrochemical reactions.

Removing Trace Moisture

Water is the enemy of battery longevity.

Even trace amounts of moisture adsorbed from the air can react with electrolyte salts during operation.

This reaction triggers electrolyte decomposition and unwanted side reactions, which compromise the battery's internal chemistry immediately upon charging.

Why Vacuum and Time are Non-Negotiable

Accessing Micropores

Electrodes are highly porous structures with complex internal geometries.

Surface drying is insufficient; the vacuum environment lowers the boiling point of liquids, allowing moisture and solvents to be extracted from deep within the micropores.

This ensures the internal active surfaces are clean and fully accessible.

Preventing Oxidation

Standard thermal drying uses hot air, which introduces oxygen to the material.

A vacuum oven extracts air, creating an inert environment.

This prevents the oxidation of delicate electrode materials that would otherwise degrade under conventional heating methods.

Enhancing Electrolyte Wetting

A thoroughly dried electrode is essentially a "thirsty" sponge.

By clearing the micropores of residues, you allow the electrolyte (such as PVA-KOH gel or liquid variations) to infiltrate the electrode arrays effectively.

This deep infiltration significantly reduces interfacial resistance, improving the battery's ability to deliver power.

Understanding the Trade-offs

The Cost of Time

The process is inherently slow, often requiring 12 hours or overnight treatment.

This creates a production bottleneck, as sheets cannot be rushed through this stage without risking incomplete drying.

Temperature Constraints

While heat accelerates drying, it must be strictly controlled (e.g., 60°C to 110°C).

Excessive heat can damage the binder or active materials, while insufficient heat fails to mobilize the trapped solvents.

The vacuum helps mitigate this by allowing evaporation at lower, safer temperatures.

Making the Right Choice for Your Goal

To optimize your battery assembly process, consider your specific performance targets:

- If your primary focus is Cycle Life: Prioritize the removal of moisture to prevent salt reactions and ensure a stable Solid Electrolyte Interface (SEI).

- If your primary focus is Power Output: Ensure the vacuum cycle is long enough to clear micropores, minimizing interfacial resistance for better electrolyte wetting.

- If your primary focus is Manufacturing Efficiency: optimize the vacuum level to lower the boiling point, potentially reducing the required dwell time without raising temperatures.

Ultimately, the vacuum bake is not just a drying step; it is the fundamental process that prepares the electrode's surface for stable electrochemical interaction.

Summary Table:

| Objective | Process Mechanism | Impact on Battery Performance |

|---|---|---|

| Solvent Removal | Evaporates residual NMP/solvents | Prevents interference with electrochemical reactions |

| Moisture Elimination | Lowers boiling point under vacuum | Prevents electrolyte decomposition and side reactions |

| Oxidation Prevention | Creates an inert, oxygen-free environment | Protects delicate electrode materials from degradation |

| Pore Clearing | Extracts trapped fluids from micropores | Enhances electrolyte wetting and reduces resistance |

Elevate Your Battery Manufacturing Precision with KINTEK

Don't let residual moisture or solvents compromise your cell's cycle life and safety. KINTEK provides industry-leading vacuum drying solutions specifically designed for the rigorous demands of electrode preparation.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Vacuum, Muffle, and CVD systems, all fully customizable to your specific temperature and pressure requirements. Whether you are optimizing for Longer Cycle Life or Maximum Power Output, our high-temp lab furnaces ensure your materials are purified for stable electrochemical performance.

Ready to optimize your assembly process? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Shasha Song, Xingqun Zhu. Synthesis and Lithium Storage Performance of CoO/CoSe Composite Nanoparticles Supported on Carbon Paper. DOI: 10.54691/k2djhp47

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do industrial molds and 10 MPa pressure impact PEEK quality? Unlock Superior Density & Structural Integrity

- What preparatory questions should be addressed before converting to electrically heated processes? Ensure a Smooth Transition to Electric Heating

- Why must Ru/GNK catalysts undergo vacuum drying? Ensure Peak Performance with Safe Desorption

- What are the limitations of functional group grafting through high-temperature heating? Achieve Chemical Precision

- What is the significance of industrial drying equipment for metal powders? Master Post-Processing & Quality Control

- What material is used in porcelain fused to metal restoration? A Guide to Alloys & Aesthetics

- What is the role of a dedicated bias power supply in low-pressure plasma nitriding? Master Ion Acceleration Control

- What is the function of a 1% CO-99% Argon gas mixture? Protect Phase Equilibrium Experiments from Oxidation