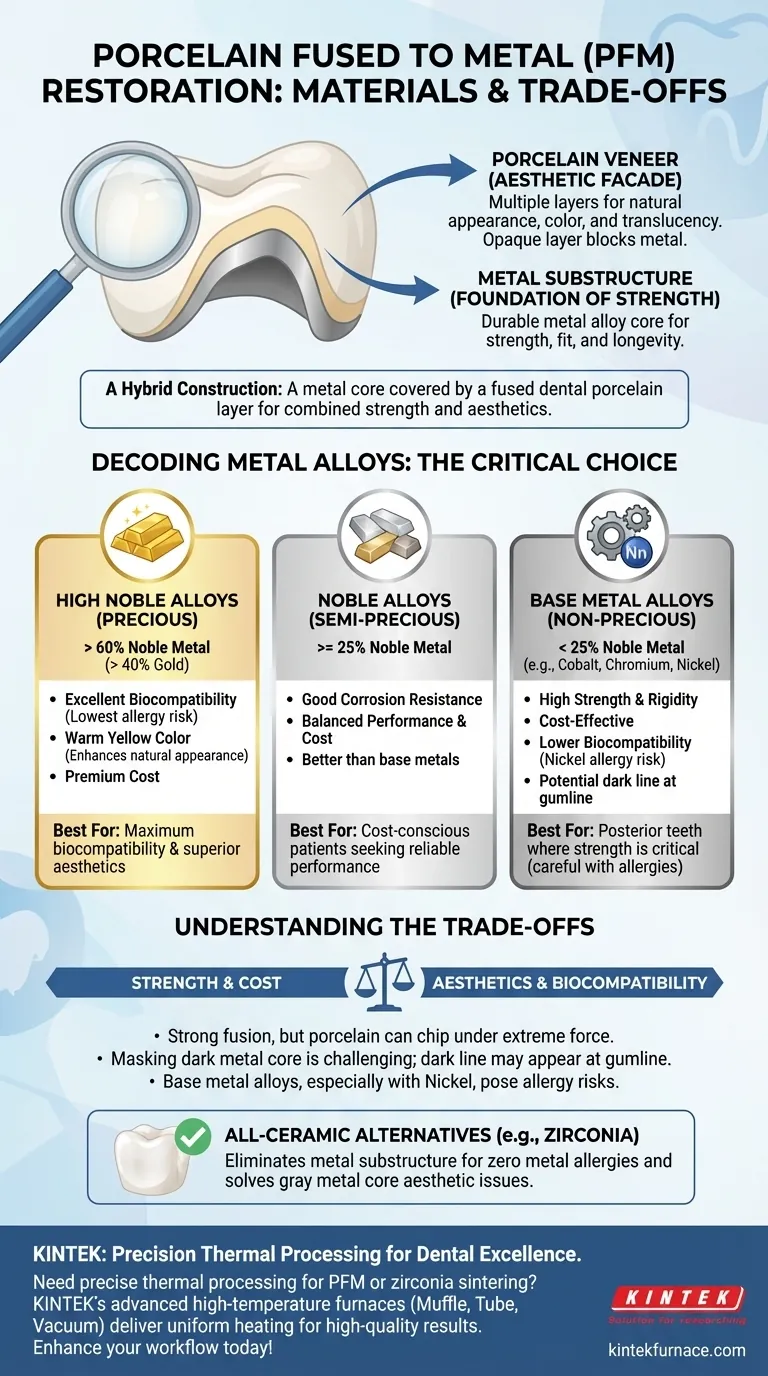

Porcelain-fused-to-metal (PFM) restorations are a hybrid construction using a metal alloy substructure for strength, which is then covered by a fused layer of dental porcelain for aesthetics. The metal component is typically made from a high noble alloy (containing gold), a noble alloy, or a base metal alloy like those containing cobalt-chromium or nickel-chromium.

The core of a PFM restoration is its two-part structure: a durable metal alloy core provides strength and a precise fit, while a porcelain overlay creates a natural, tooth-like appearance. The specific metal alloy chosen is the most critical factor, dictating the restoration's biocompatibility, longevity, and cost.

The Anatomy of a PFM Crown

A PFM restoration is not a single material but a precisely engineered combination of two distinct layers bonded together through a high-heat firing process. Each layer serves a critical function.

The Metal Substructure: The Foundation of Strength

The inner core of the restoration is a thin, cap-like structure cast from a dental alloy. This metal substructure is what provides the majority of the PFM's durability and resistance to chewing forces.

It is also responsible for ensuring a precise fit over the prepared tooth, which is crucial for preventing future decay and ensuring the longevity of the crown.

The Porcelain Veneer: The Aesthetic Facade

Fused to the outside of the metal substructure are multiple layers of dental porcelain, a type of ceramic. An initial opaque layer is applied to block the dark color of the underlying metal from showing through.

Subsequent layers of porcelain are then artfully applied and shaped by a dental technician to mimic the color, translucency, and contours of a natural tooth. This layering is what gives the PFM its aesthetic quality.

Decoding the Metal Alloys

The choice of metal alloy is the single most important variable in the quality of a PFM restoration. Alloys are categorized based on their content of "noble" metals (like gold and platinum group metals), which are highly resistant to corrosion and oxidation.

High Noble Alloys (Precious)

These are considered the gold standard, containing over 60% noble metal, with at least 40% being gold. Gold alloys are exceptionally biocompatible, minimizing the risk of allergic reactions or tissue irritation.

Their warm, yellowish color also provides a better underlying shade for the porcelain, making it easier to achieve a natural-looking result compared to the gray of other metals.

Noble Alloys (Semi-Precious)

These alloys have at least 25% noble metal content. They offer a good balance of performance and cost, providing better corrosion resistance than base metals but at a lower price point than high noble alloys.

Base Metal Alloys (Non-Precious)

These contain less than 25% noble metal and are primarily composed of materials like cobalt, chromium, and nickel. These alloys are very strong, rigid, and cost-effective.

However, they are less biocompatible. Nickel, in particular, is a common allergen, making these alloys unsuitable for sensitive patients. They can also lead to a visible dark or gray line at the gumline over time.

Understanding the Trade-offs

While PFM restorations have a long track record of success, they represent a series of compromises between strength, aesthetics, and cost. Understanding these is key to knowing their place among modern dental options.

Strength vs. Aesthetics

The fusion of metal and porcelain creates a strong restoration, but it isn't perfect. The porcelain layer, while beautiful, can be brittle and may chip or fracture off the metal core under extreme force.

Furthermore, completely masking the dark metal core is a challenge. A dark line can sometimes become visible at the gumline, especially if the gums recede over time.

Biocompatibility Concerns

As noted, the primary concern with PFM restorations is the potential for metal allergies, specifically with base metal alloys containing nickel. High noble gold alloys are the safest choice to avoid adverse tissue reactions.

The Rise of All-Ceramic Alternatives

Modern dental technology has introduced materials like zirconia, an extremely strong all-ceramic material. Zirconia restorations eliminate the metal substructure entirely, solving the aesthetic problem of the gray metal core and removing any risk of metal allergies.

Making the Right Choice for Your Goal

The best material depends entirely on the clinical situation, patient factors, and desired outcome.

- If your primary focus is maximum biocompatibility and premium aesthetics: A PFM with a high noble (gold) alloy is the superior choice, minimizing allergy risk and providing a warm foundation for the porcelain.

- If your primary focus is strength and cost-effectiveness: A PFM with a base metal (cobalt-chromium) alloy offers excellent durability for posterior teeth at a lower cost, but the potential for allergies must be carefully evaluated.

- If your primary focus is the absolute best aesthetics with zero metal: You should explore modern all-ceramic options like zirconia, which avoid the compromises of the PFM's metal substructure.

Understanding the fundamental material differences empowers you to make a more informed decision for long-term dental health.

Summary Table:

| Metal Alloy Type | Key Characteristics | Best For |

|---|---|---|

| High Noble (e.g., Gold) | Excellent biocompatibility, warm color for natural aesthetics, premium choice | Patients prioritizing biocompatibility and superior aesthetics |

| Noble (Semi-Precious) | Good corrosion resistance, balanced cost and performance | Cost-conscious patients seeking reliable performance |

| Base Metal (e.g., Cobalt-Chromium) | High strength, rigid, cost-effective | Posterior teeth where strength is critical (check for nickel allergies) |

Need precise thermal processing for dental alloy development or ceramic firing? KINTEK's advanced high-temperature furnaces are engineered to meet the exacting demands of dental laboratories and manufacturers. Whether you are sintering zirconia for all-ceramic restorations or fusing porcelain to metal substrates, our Muffle, Tube, and Vacuum Furnaces deliver the uniform heating and precise temperature control essential for consistent, high-quality results. Leverage our deep customization capabilities to tailor a furnace solution for your unique PFM or all-ceramic production line. Contact us today at #ContactForm to enhance your dental restoration workflows!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations