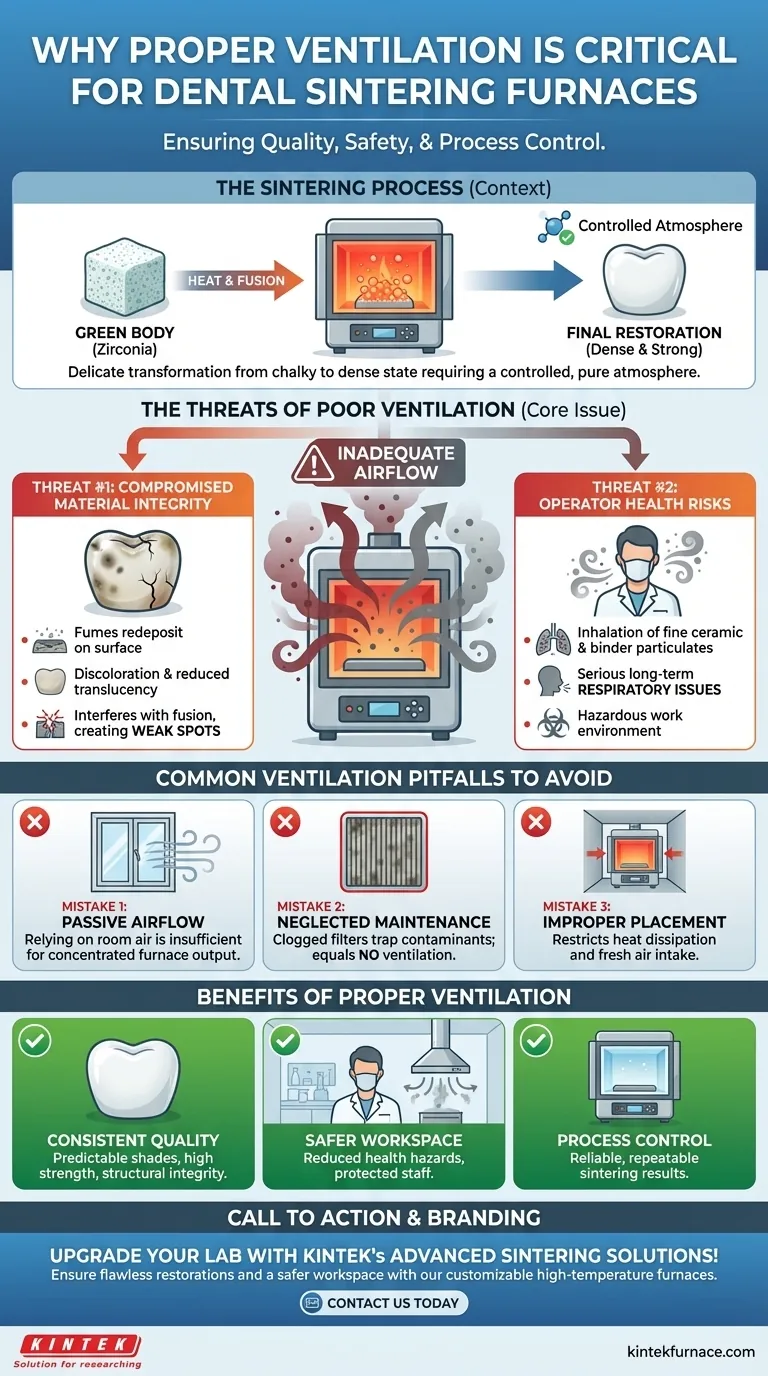

Proper ventilation is a critical operational requirement for any dental sintering furnace. Inadequate airflow allows fumes and contaminants to build up within the furnace chamber and the lab environment, which directly compromises the quality of the final dental restoration and poses significant health risks to technicians.

The core issue is that sintering inherently releases byproducts. Managing these byproducts through proper ventilation is not just a safety measure; it is a fundamental process control that ensures the structural integrity of your restorations and protects the health of your staff.

The Role of Sintering in Modern Dentistry

To understand why ventilation is so crucial, you must first understand the sintering process itself. It is a precise thermal treatment, not simply a heating and cooling cycle.

From Green Body to Final Restoration

Sintering transforms a chalky, milled "green body" of zirconia into its final, dense, and incredibly strong state. The furnace heats the material to a temperature just below its melting point, causing the individual ceramic particles to fuse and condense. This process creates the hardness, strength, and biocompatibility required for a permanent dental restoration.

The Need for a Controlled Atmosphere

This transformation is a delicate chemical and physical process. The final properties of the sintered zirconia are highly dependent on the stability and purity of the atmosphere inside the furnace during the cycle. Any contaminants introduced can disrupt this process.

How Poor Ventilation Undermines Quality and Safety

When ventilation is insufficient, the byproducts released during heating become trapped. This leads to two primary failures: compromised material quality and a hazardous work environment.

Threat #1: Compromised Material Integrity

Fumes and airborne particles released during sintering do not simply vanish. In a poorly ventilated chamber, they can redeposit onto the surface of the restoration. This can lead to discoloration, reduced translucency, and an unpredictable final shade. More critically, these contaminants can interfere with the crystalline fusion, potentially creating weak spots that compromise the restoration's long-term structural integrity.

Threat #2: Operator Health Risks

The fumes generated during sintering are not harmless water vapor. They are a complex mixture of microscopic particulates from the ceramic material and any binding agents. Inhaling these fine particles over time can pose a serious health risk to lab technicians, contributing to respiratory issues and other long-term concerns.

Common Ventilation Pitfalls to Avoid

Achieving proper ventilation requires more than just placing the furnace near a window. Many well-intentioned labs make critical errors that negate their efforts.

Mistake 1: Relying on Passive Airflow

A room may feel "well-ventilated," but this passive airflow is often insufficient to handle the concentrated output of a sintering furnace. Without an active exhaust system, fumes can easily accumulate in the workspace, especially during long or repeated firing cycles.

Mistake 2: Neglecting Maintenance

Many furnaces have built-in ventilation filters. However, these filters become clogged over time with dust and particulates. A clogged filter is functionally equivalent to having no ventilation at all, trapping contaminants and forcing the furnace's fans to work harder, which can lead to premature failure.

Mistake 3: Improper Furnace Placement

Placing a furnace in a tight corner or a small, enclosed room is a common mistake. This restricts airflow around the unit, preventing heat from dissipating effectively and hampering the unit's ability to draw in clean air and expel fumes.

Making the Right Choice for Your Goal

Your ventilation strategy should be tailored to the scale of your operation and your primary objectives.

- If your primary focus is consistent restoration quality: Ensure the furnace has a dedicated exhaust path to prevent any contaminants from re-entering the sintering chamber.

- If your primary focus is lab safety in a small setup: Position the furnace in a well-ventilated area, commit to a strict schedule for inspecting and cleaning filters, and ensure good ambient airflow.

- If your primary focus is scaling production: Invest in a dedicated, active exhaust system that vents fumes directly from the furnace to the outside of the building.

By treating ventilation as an essential component of the sintering process itself, you gain direct control over the quality, safety, and consistency of your lab's output.

Summary Table:

| Aspect | Impact of Poor Ventilation | Benefit of Proper Ventilation |

|---|---|---|

| Material Quality | Discoloration, weak spots, reduced translucency | Consistent color, strength, and structural integrity |

| Operator Safety | Respiratory risks from inhaling fumes | Safe work environment, reduced health hazards |

| Process Control | Contaminants disrupt sintering atmosphere | Reliable, high-quality dental restorations |

Upgrade your dental lab with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, and Vacuum & Atmosphere Furnaces, with deep customization to meet your unique needs. Ensure flawless restorations and a safer workspace—contact us today to discuss how our products can enhance your lab's efficiency and output quality.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab