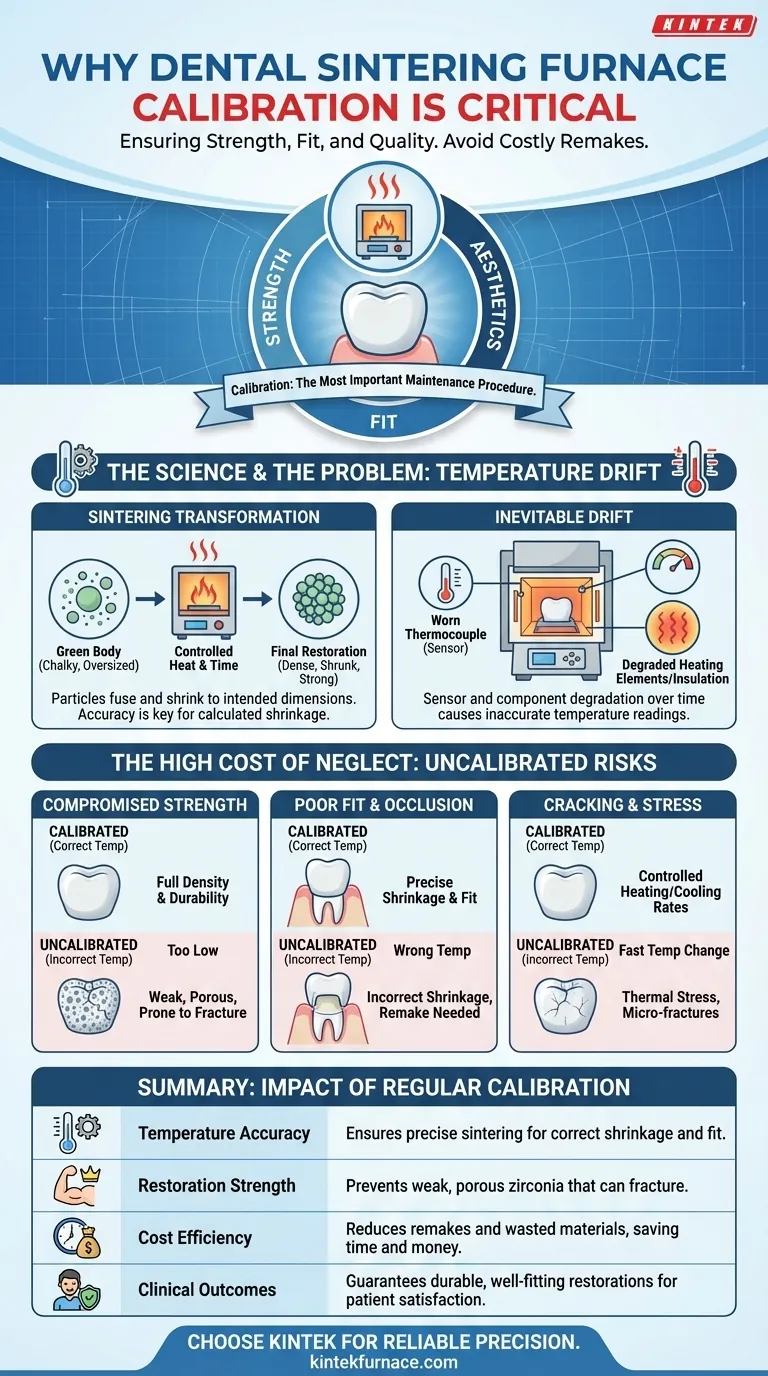

In short, calibration is the single most important maintenance procedure for your dental sintering furnace. It directly ensures the final restoration's strength, fit, and aesthetic quality by guaranteeing the furnace reaches and holds the precise temperatures required by materials like zirconia. Without it, you are operating blind, risking failed restorations and costly remakes.

The core issue is not whether your furnace turns on, but whether it achieves the exact temperature profile required for successful sintering. Over time, all furnaces experience "temperature drift," and regular calibration is the only way to correct it, safeguarding your clinical outcomes and your bottom line.

Why Temperature Accuracy Is Everything in Sintering

Sintering is a process of thermal transformation. It converts a chalky, oversized milled restoration (a "green body") into a dense, strong, and precisely fitting final product.

The Science of Sintering

During the sintering cycle, fine ceramic particles are heated to a temperature just below their melting point. This causes the particles to fuse, condensing the material and shrinking the restoration to its final, intended dimensions.

This process is what gives a material like zirconia its exceptional hardness, strength, and biocompatibility. The final properties are a direct result of the temperature and time it was exposed to during the cycle.

Accounting for Shrinkage

The significant shrinkage that occurs during sintering is a calculated variable. Restorations are intentionally milled larger to compensate for this. This calculation assumes the furnace will execute the sintering program with perfect accuracy.

If the temperature is off, the shrinkage will be incorrect, leading to a restoration that simply does not fit.

The Inevitable Problem: Temperature Drift

A furnace's ability to control temperature is not static. It degrades over time due to the harsh operating environment, a phenomenon known as temperature drift.

The Thermocouple's Degradation

The thermocouple is the furnace's temperature sensor. Constant exposure to extreme heat, chemical vapors, and soiling causes it to lose accuracy. It may report a temperature that is significantly different from the actual temperature inside the chamber.

Heating Element and Insulation Wear

Heating elements also wear out, becoming less efficient at producing heat. Likewise, the furnace's insulation can degrade or become contaminated with deposits, leading to heat loss and uneven temperature distribution within the chamber.

Calibration verifies that all these components—the sensor, the heat source, and the insulation—are working together to produce an accurate and stable thermal environment.

The High Cost of an Uncalibrated Furnace

Neglecting calibration directly translates to clinical failures, wasted resources, and frustrated patients. The consequences of inaccurate sintering temperatures are predictable and severe.

Compromised Strength and Durability

If the peak temperature is too low, the zirconia will not achieve full density. This results in a weak, porous restoration that is prone to premature failure and fracture in the patient's mouth.

Poor Fit and Occlusion

If the furnace temperature is inaccurate, the shrinkage factor will be wrong. A furnace running too hot can cause over-shrinkage, while one running too cool will cause under-shrinkage. In either case, the crown will not fit the preparation, leading to a costly remake.

Cracking and Material Stress

Proper sintering relies on controlled heating and cooling rates. An uncalibrated furnace can heat or cool too quickly, inducing thermal stress within the material and causing micro-fractures that compromise the restoration's integrity.

Making the Right Choice for Your Practice

Think of calibration not as a cost, but as an essential quality control step that protects your work. The decision to calibrate consistently is a decision to control the outcome.

- If your primary focus is clinical excellence: Regular calibration is the only way to guarantee your restorations have the strength, fit, and longevity your patients deserve.

- If your primary focus is operational efficiency: Calibration is a direct investment in reducing remakes, minimizing wasted materials, and saving valuable chair time.

Ultimately, calibrating your sintering furnace gives you control over a critical step in your production chain, ensuring every restoration you deliver is your best work.

Summary Table:

| Aspect | Impact of Calibration |

|---|---|

| Temperature Accuracy | Ensures precise sintering for correct shrinkage and fit |

| Restoration Strength | Prevents weak, porous zirconia that can fracture |

| Cost Efficiency | Reduces remakes and wasted materials, saving time and money |

| Clinical Outcomes | Guarantees durable, well-fitting restorations for patient satisfaction |

Ensure your dental lab's success with reliable, high-performance sintering furnaces from KINTEK. Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today to discuss how our furnaces can enhance your precision and efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations